Solvent-out crystallization process of extracting aluminum oxide in coal ash by acid process

A technology for dissolving crystallization and alumina, applied in alumina/aluminum hydroxide, chemical industry, chlorine/hydrogen chloride, etc., can solve the problems of equipment corrosion and high investment cost, reduce equipment corrosion, reduce system investment cost, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

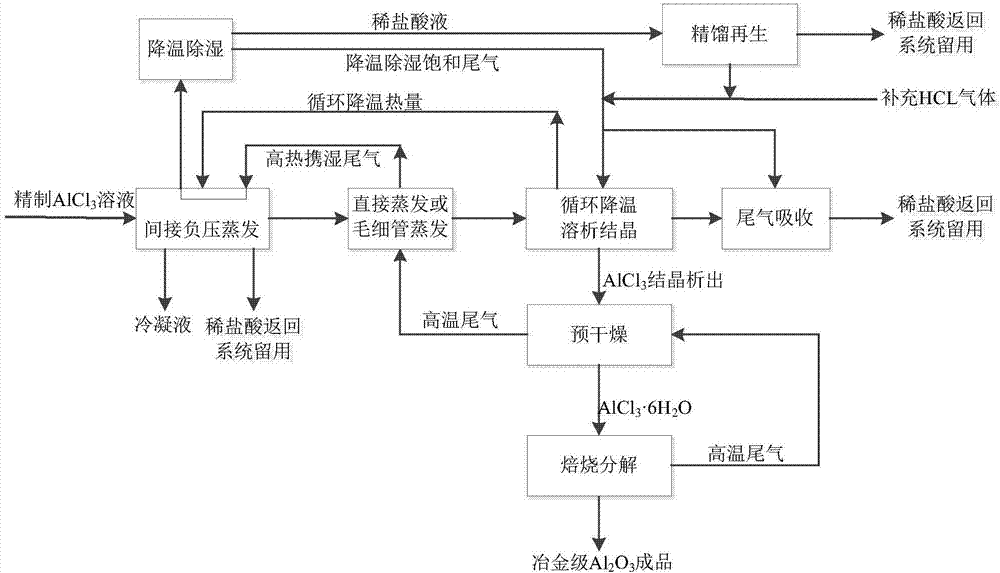

[0026] Such as figure 1 As shown, a dissolution and crystallization process for extracting alumina in fly ash by acid method, the treatment of HCl-containing high-temperature roasting tail gas, the recovery and utilization of HCl gas, the recovery and utilization of AlCl 3 The three processes of solution evaporation and concentration are organically coupled, and the specific steps are as follows:

[0027] Step A. Pre-dry the crystalline AlCl from the crystallization section with the HCl-containing high-temperature roasting tail gas (temperature about 150-400°C) from the high-temperature roasting unit 3 ;

[0028] Step B, then use the remaining sensible heat (temperature is about 100°C) and unsaturated moisture carrying capacity of the HCl-containing high-temperature roasting tail gas to pre-concentrate the refined AlCl 3 The solution was re-concentrated to near saturation;

[0029] Step C, then the high-heat HCl-containing wet tail gas (temperature is about 70-80 ° C) is us...

Embodiment 2

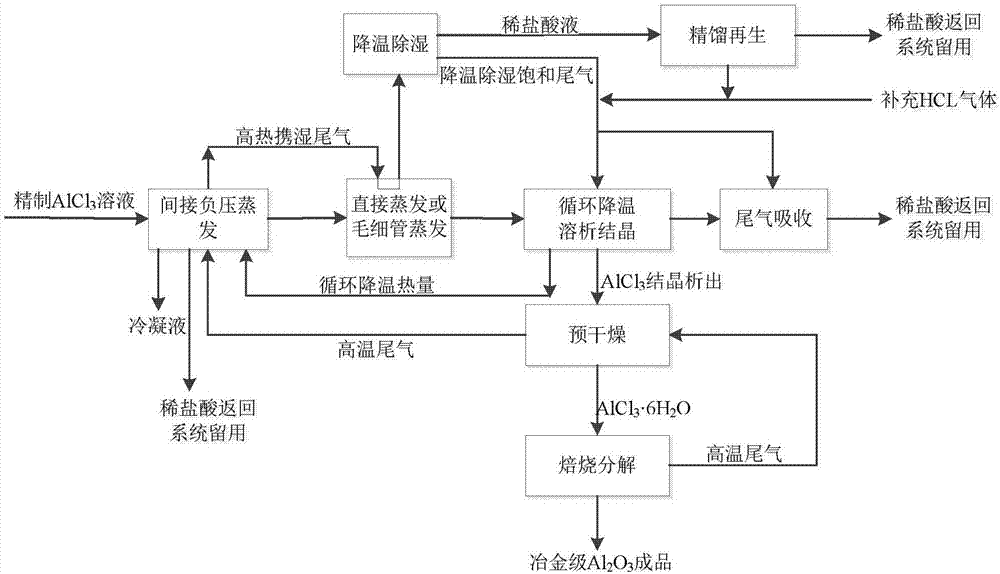

[0038] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the adaptive selection is carried out according to the different composition ratios of HCl-containing high-temperature roasting tail gas, and the order of step B and step C is changed. The specific process is as follows:

[0039] Step A, firstly use HCl-containing high-temperature roasting tail gas to pre-dry the crystalline AlCl from the crystallization section 3 crystal;

[0040] Step B, then use the remaining sensible heat and unsaturated moisture carrying capacity of the HCl-containing high-temperature roasting tail gas to refine AlCl 3 The solution is pre-concentrated;

[0041]Step C, then the high-heat HCl-containing tail gas is used to carry the wet tail gas to the pre-concentrated refined AlCl 3 The solution was re-concentrated to near saturation;

[0042] Step D, then send the HCl-containing saturated tail gas that has been cooled and dehumidified to the crystallization secti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap