Ultrasonic-extrusion reinforcement method and device for structural part connecting hole

A technology for strengthening devices and connecting holes, applied in the field of machining, can solve the problems of unable to change the vibration mode, unable to adapt to the requirements of hole strengthening, etc., to avoid the reaming process, eliminate wall scratches, and consume less energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing, this method is clearly described in further detail.

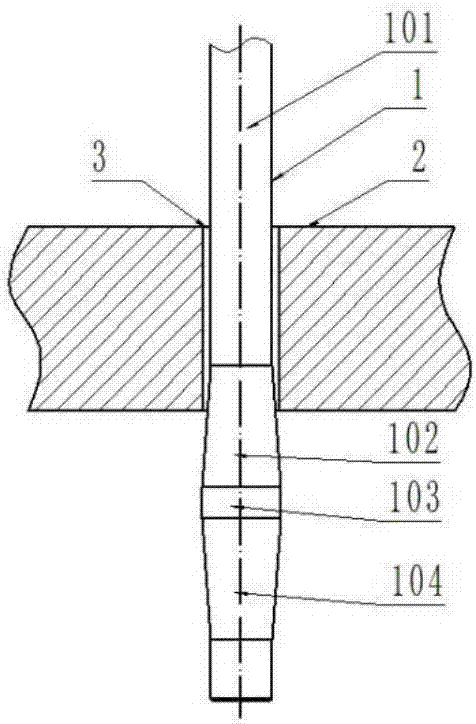

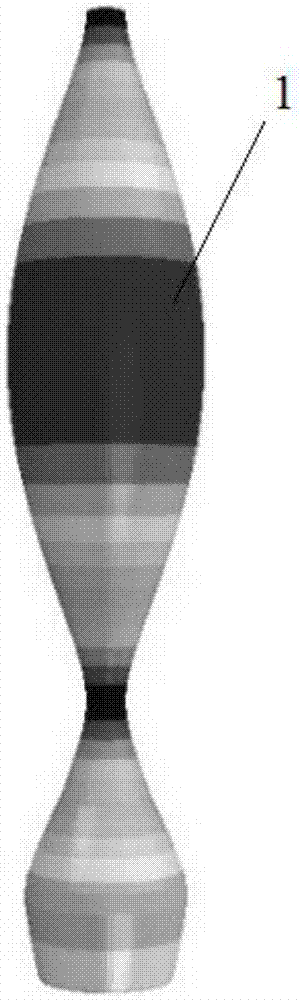

[0059] The present invention is an ultrasonic extrusion strengthening method for connecting holes 3 of structural parts. The method operates with a breath-type ultrasonic vibration mandrel 1 as an extrusion tool, and the vibration state of the breath-type ultrasonic vibration mandrel is as follows: figure 2 . The extrusion mandrel used is a cylindrical tool such as figure 1 , including a guide section 101, a front cone section 102, a working section 103, and a rear cone section 104.

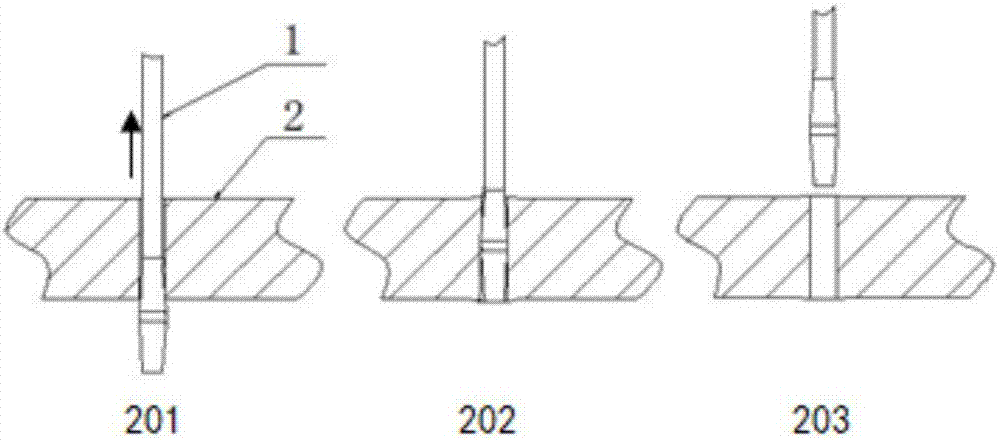

[0060] The principle of the ultrasonic extrusion strengthening method of the present invention is as follows: figure 1 As shown, there is a connection hole 3 on the mother plate 2 of the structural part, and the axis of the mandrel 1 is aligned with the axis of the connection hole 3 under the condition that the mandrel 1 and the connection hole 3 maintain an extrusion margin of 2% to 6%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com