Adjustable preset powder laying device used for laser cladding

A powder spreading device and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problem of non-adjustable powder spreading thickness and powder spreading area, difficult control of powder spreading thickness and area, and difficulty of powder spreading specific area. Control and other issues, to achieve the effect of easy mass production, easy control and adjustment, and convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

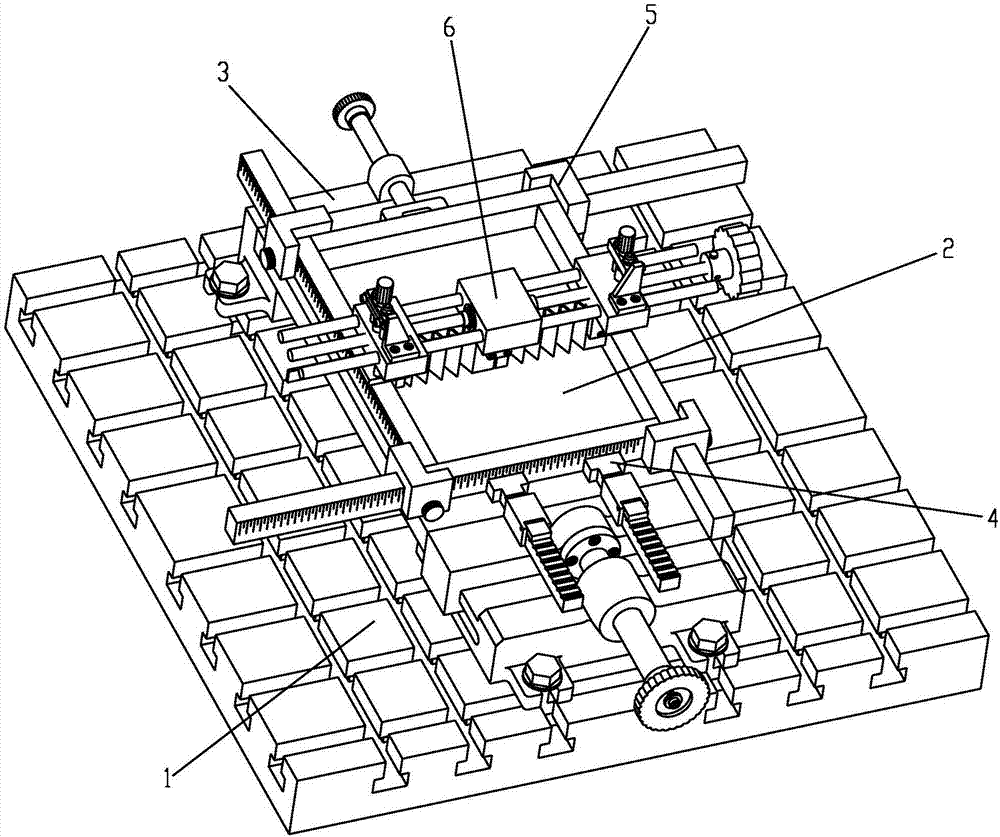

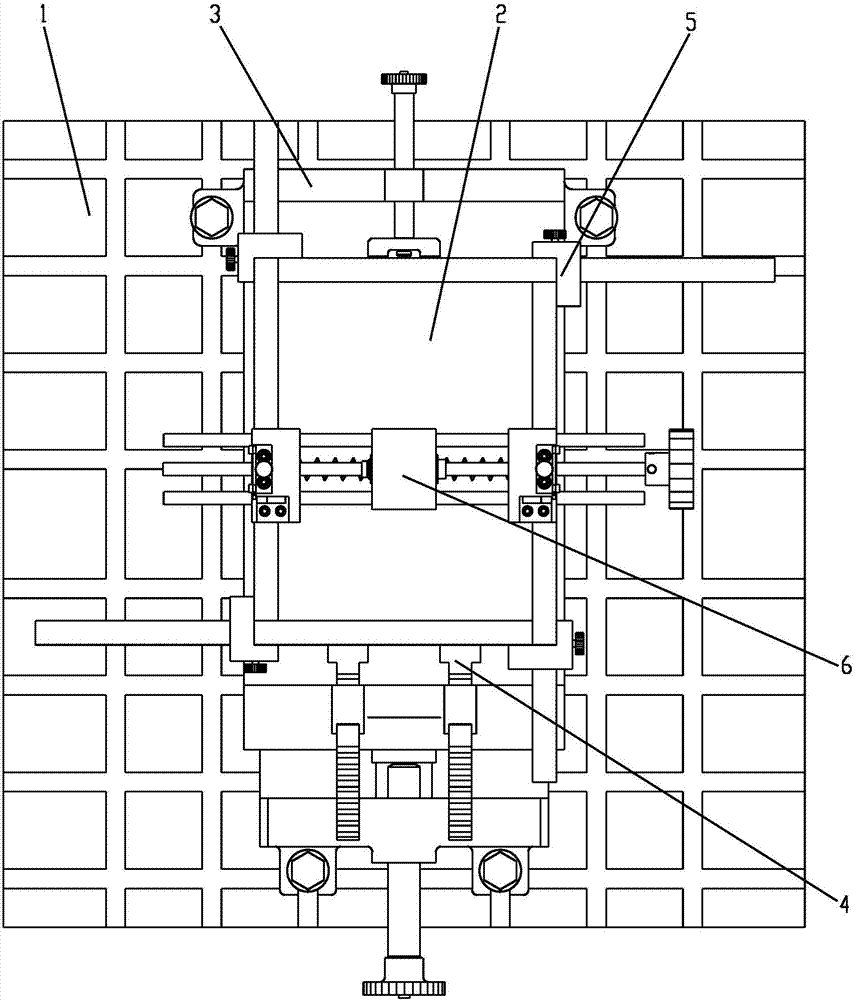

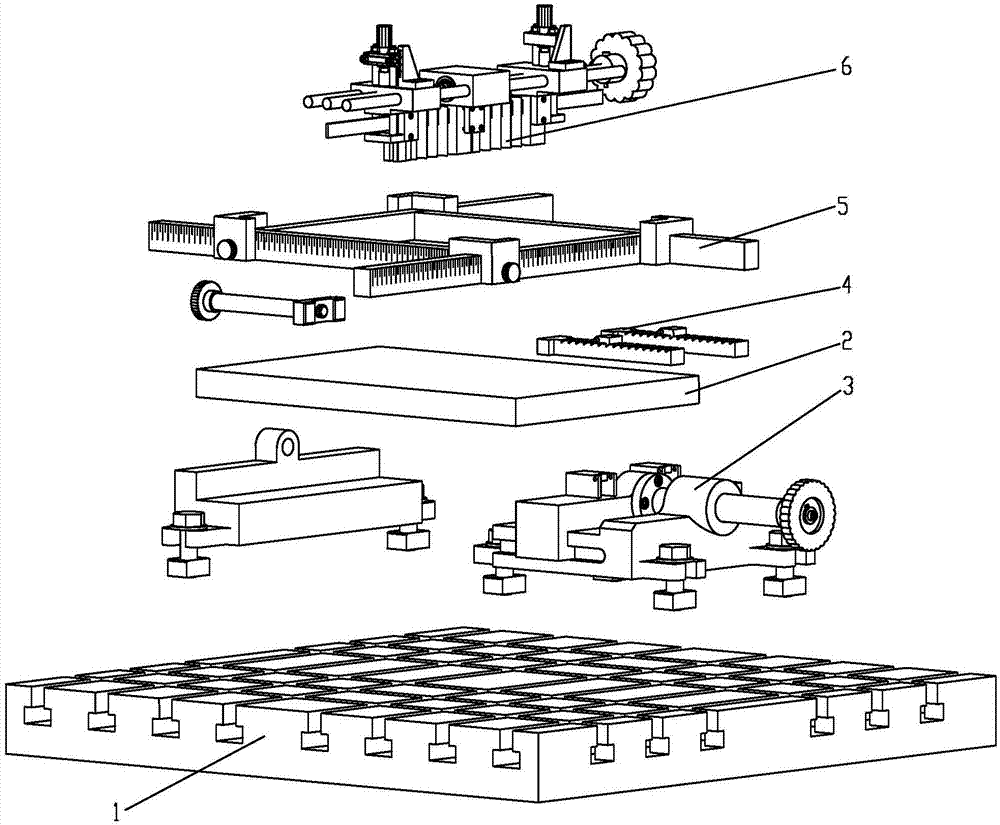

[0054] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the adjustable preset powder spreading device for laser cladding of the present invention includes a workbench 1, a substrate 2 arranged above the workbench 1, and a substrate installed on the workbench 1 and used to fix the substrate 2 A clamping mechanism 3, the base plate 2 is provided with a frame assembly 5 with adjustable length and width, the base plate clamping mechanism 3 is equipped with a frame clamping mechanism 4 for fixing the frame assembly 5, the frame assembly 5 A height-adjustable mobile beam mechanism 6 is arranged on the top; the mobile beam mechanism 6 includes two guide blocks 6-4 and an intermediate block 6-5 arranged between the two guide blocks 6-4, and the intermediate block 6 -5 is perforated along the horizontal direction with a two-way lead screw 6-8 for driving the guide block 6-4 to move back and forth, and a telescopic curtain 6-12 that can expand and contract in the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com