Semi-automatic dyeing cleaning system

A semi-automatic, dyeing roller technology, applied in the field of textile printing and dyeing, can solve the problems of time-consuming and labor-intensive cleaning of dyeing rollers, and achieve the effects of saving manpower, high cleaning efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

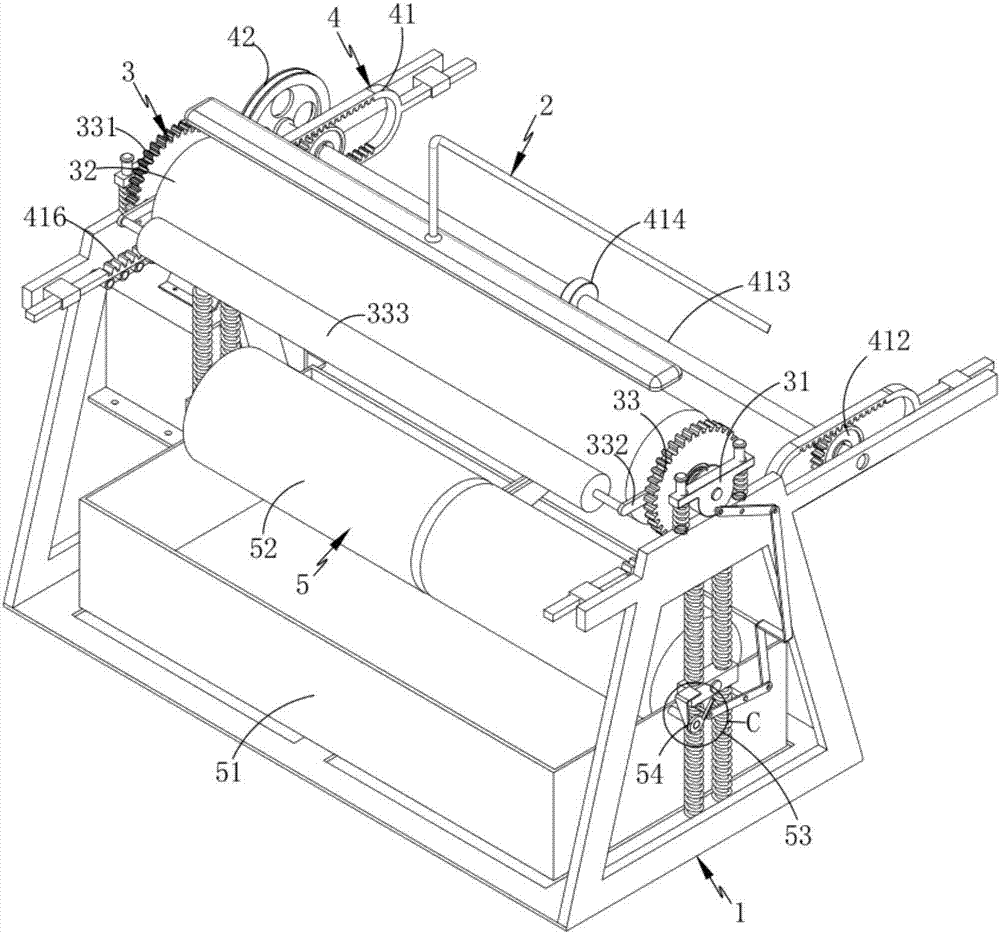

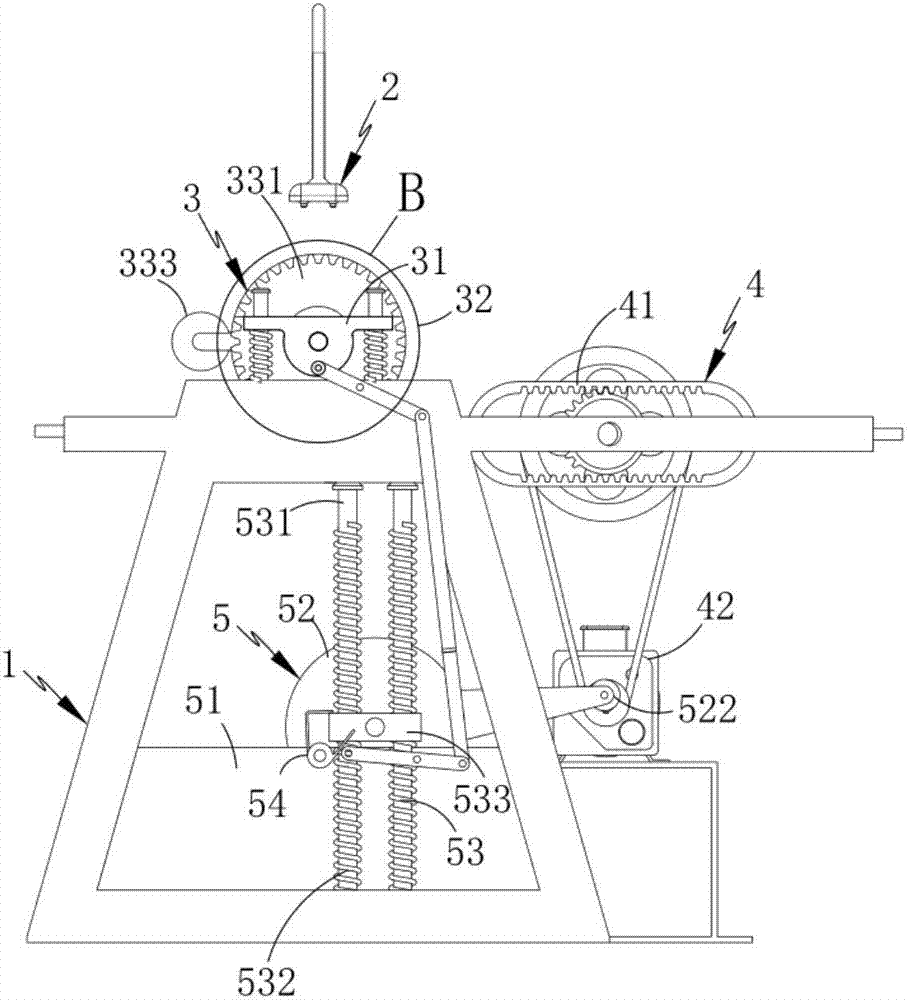

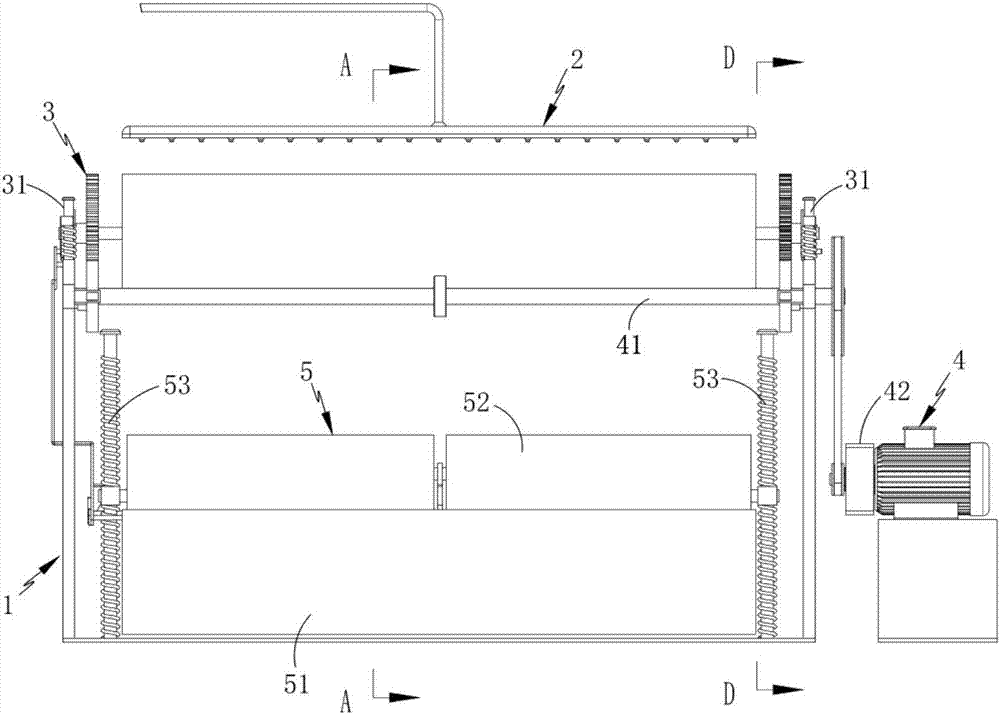

[0063] Such as figure 1 , 2, 3, a semi-automatic dyeing cleaning system, including a frame 1 and a dyeing mechanism 2, also includes:

[0064] A dyeing mechanism 3, the two ends of the dyeing mechanism 3 are respectively arranged on the frame 1 through the first elastic component 31, and are located below the spraying mechanism 2;

[0065] The transmission mechanism 4 includes a transmission assembly 41 arranged on the dyeing frame 1 and a drive assembly 42 that drives the transmission assembly 41 for reciprocating motion; and

[0066] Cleaning mechanism 5, described cleaning mechanism 5 is arranged on the below of described dyeing mechanism 3, and it comprises:

[0067] Washing tank 51;

[0068] A cleaning assembly 52, the cleaning assembly 52 is located inside the wash...

Embodiment 2

[0102] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is: as Figure 4 As shown, it also includes a linkage assembly 6 installed on the frame 1 and arranged on the same side as the locking assembly 54. The linkage assembly 6 includes:

[0103] A first swing rod 61, the first swing rod 61 is rotatably mounted on the frame 1 and is rotatably connected with the mounting block 313;

[0104] The second swing rod 62, the second swing rod 62 is rotatably mounted on the washing tank 51, one end of which is rotatably connected with the first swing rod 61 via a traction link 63, and the other end is connected with the locking assembly 54 contact settings.

[0105] Install the linkage assembly 6 on the same side of the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com