Oilfield surface facilities

An impeller, gas-liquid separation technology, used in wellbore/well components, production fluids, earth-moving drilling and other directions, can solve the problems of large volume, poor separation effect, inaccurate three-phase measurement of oilfield liquid production, etc., to achieve separation effect Good, simple structure, fast and efficient gas-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

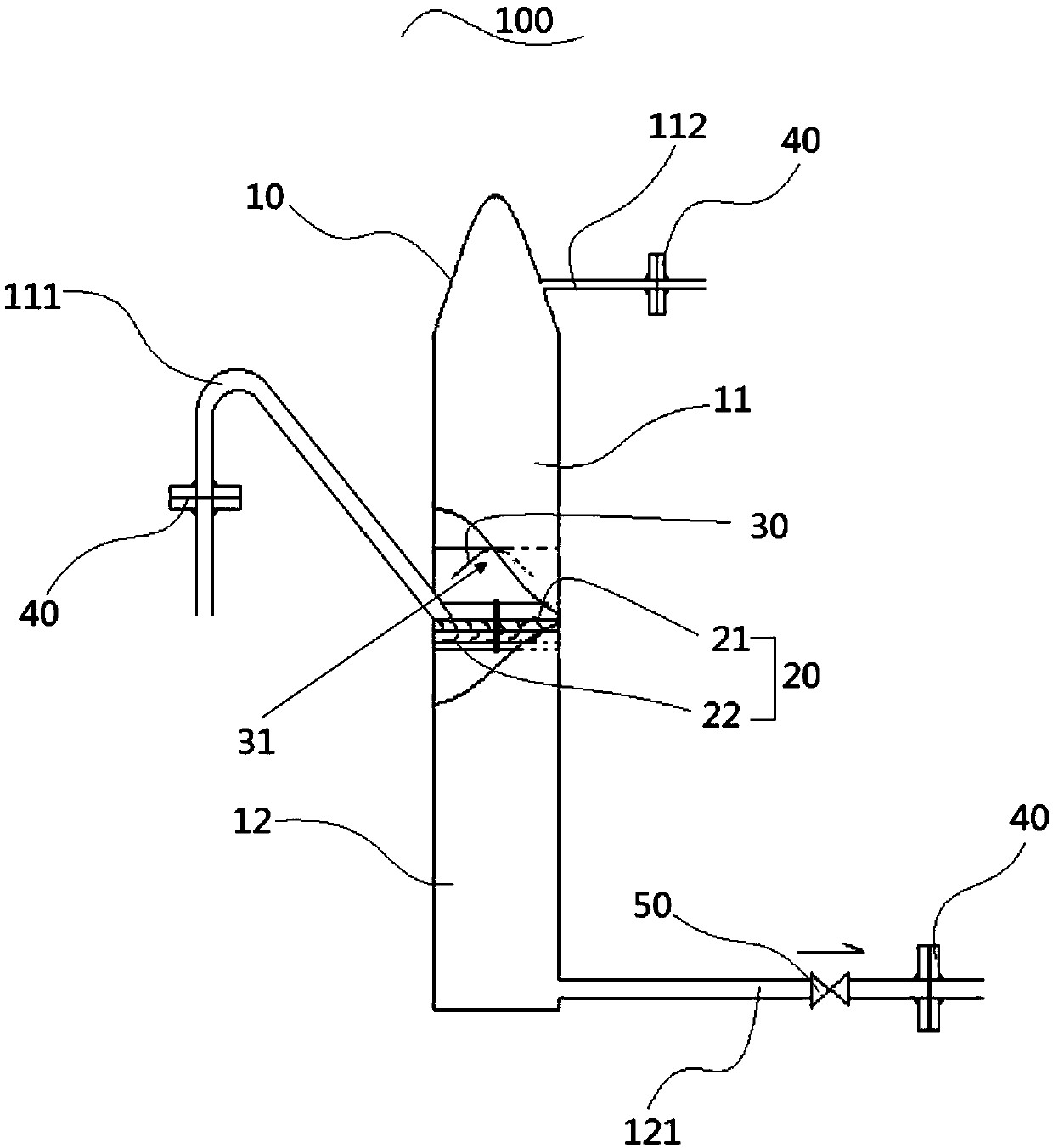

[0033] see figure 1 , which shows a gas eliminator 100 for gas-liquid separation according to an embodiment of the present invention. The gas eliminator 100 includes a gas-liquid separation column 10, a centrifugal assembly 20 and a gas phase shroud 30, and the centrifugal assembly 20 and the gas phase shroud 30 are all accommodated in the inner chamber of the gas-liquid separation column 10, and the centrifugal assembly 20 and the gas phase The shrouds 30 are spaced apart from each other. Specifically, when in use, the oilfield production fluid is sprayed into the centrifugal assembly 20, and then the centrifugal assembly 20 and the gas phase shroud 30 cooperate with each other to realize the first centrifugal separation and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com