an oil return converter

A technology of converters and fuel tanks, which is applied in the direction of machines/engines, charging systems, liquid fuel feeders, etc., to achieve the effects of convenient application, simple structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

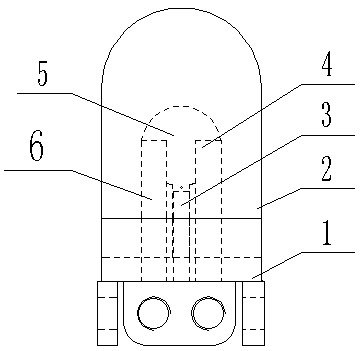

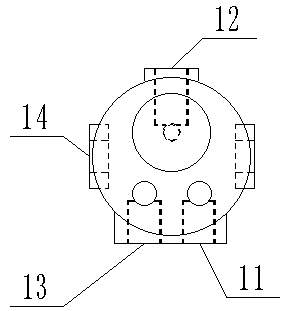

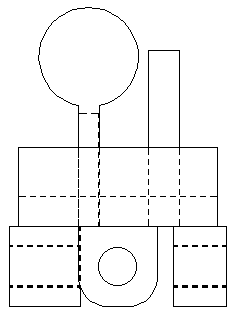

[0022] The oil return converter is installed on the oil return road of the engine, such as figure 1 , figure 2 and image 3 As shown, the oil return converter includes a mounting base 1, on which a cover 2 is connected, and the mounting base 1 is screwed to the cover 2 to form a cavity capable of accommodating the return oil. The oil control pipe 3 is installed on the mounting base 1, the oil control pipe 3 is a hollow cavity, and its shape can be a cylinder, a square, etc., and there are several holes near the wall of the mounting base 1, and the diameter of the hole is about 1mm , arranged equidistantly along the circumferential direction of the pipe wall, and more than two circles of holes are set from bottom to top. There is no limit to the shape of the holes, which can be round, square, special-shaped and other shapes. A floating device 5 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com