Locking connection device and method for steel rope heads with tensile force

A technology of connecting device and rope head, applied in the direction of belt/chain/gear, transmission element or pulley rope or cable, textile cable, etc. Avoid personal injury accidents, facilitate operation, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

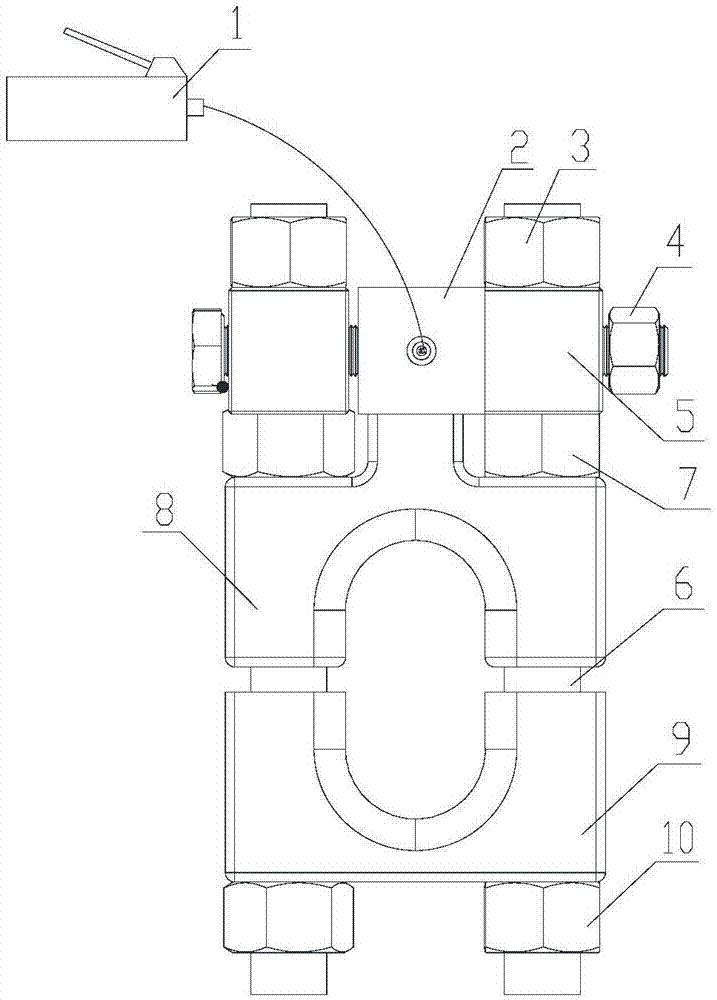

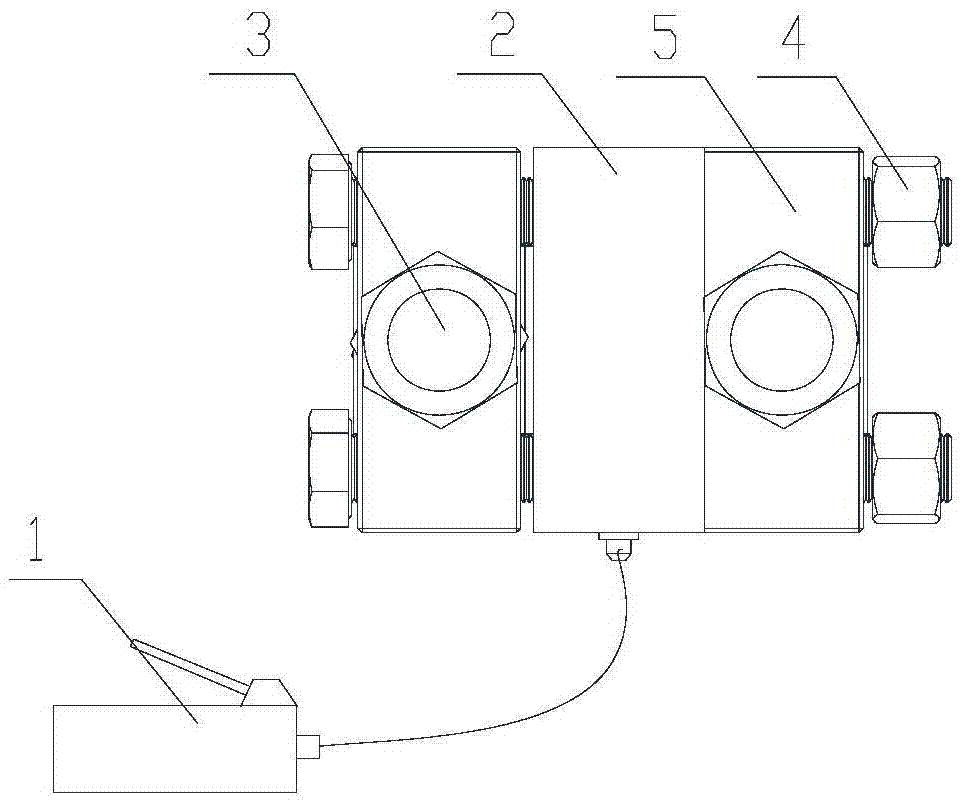

[0017] As can be seen from the accompanying drawings, the tensioned steel rope head locking connection device of the present invention is composed of a pressure pump 1, a hydraulic cylinder 2, a pressure nut 3, an adjusting bolt 4, a guide block 5, a guide rod 6, a safety nut 7, a locking Tight block 8, lower locking block 9 and pre-tightening nut 10 are formed.

[0018] The pressure pump 1 is connected with the hydraulic cylinder 2, and a guide block 5 with a hole in the middle is provided on both sides of the hydraulic cylinder 2 respectively, and the two guide blocks 5 are connected together laterally by two adjusting bolts 4 . The lower end of the cylinder rod of the hydraulic cylinder 2 is connected to an upper locking block 8, and a lower locking block 9 is arranged below the upper locking block 8, and a "U"-shaped slot is correspondingly opened in the middle of the upper locking block 8 and the lower locking block 9, Both sides are provided with guide rod holes, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com