Heating type integrated urea pipe

A urea tube, an integrated technology, applied in the direction of pipeline heating/cooling, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of unsafe heating method, inability to completely thaw, slow heating speed, etc., to shorten heating and thawing The effect of time, heating power is stable and heating speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

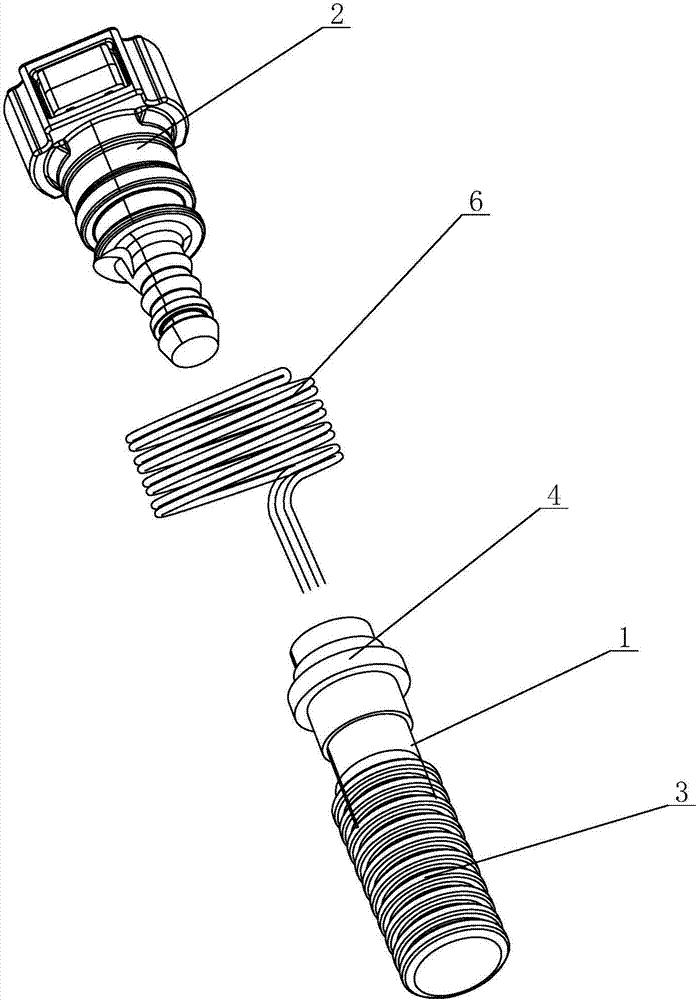

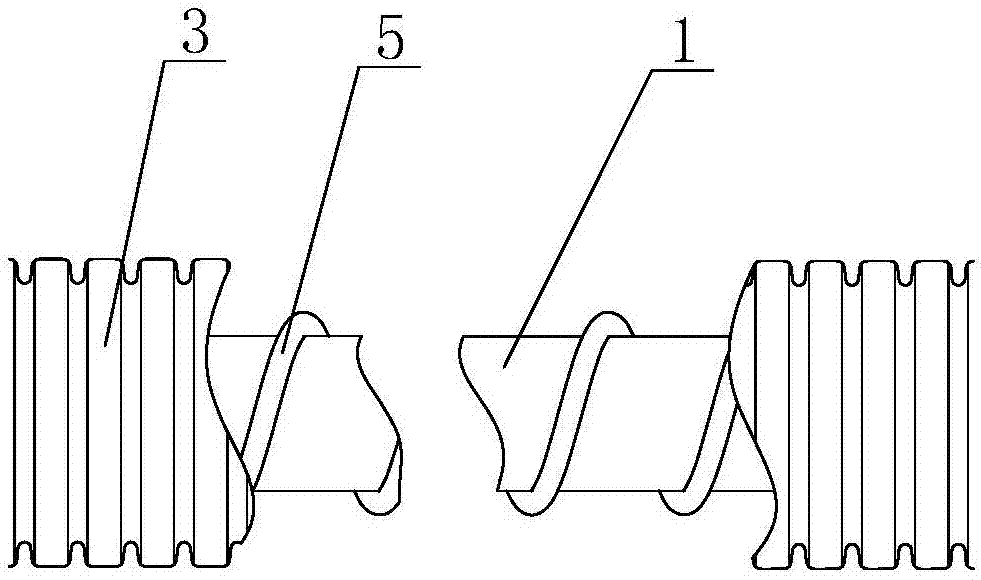

[0016] see figure 1 and figure 2 As shown, in this embodiment, a heated integrated urea tube includes a nylon tube body 1 for transporting urea, the end of the nylon tube body 1 is provided with a quick-plug joint 2, and the nylon tube body 1 The outer jacket is provided with a corrugated tube 3, and the connection between the quick-plug connector 2 and the nylon tube body 1 is provided with an overflow stopper 4, and the nylon tube body 1 is wound with a helical tube body heating wire 5. The pipe body heating wire 5 is covered with a Teflon high temperature resistant layer, and the quick-plug connector 2 is evenly wound with a spiral joint heating wire 6, and the joint heating wire 6 is covered with a high temperature resistant tape for fixing. Finally, it is packaged with plastic to form an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com