A kind of microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and dielectrics, applied in ceramics, inorganic insulators, etc., can solve problems such as effects and controllability need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

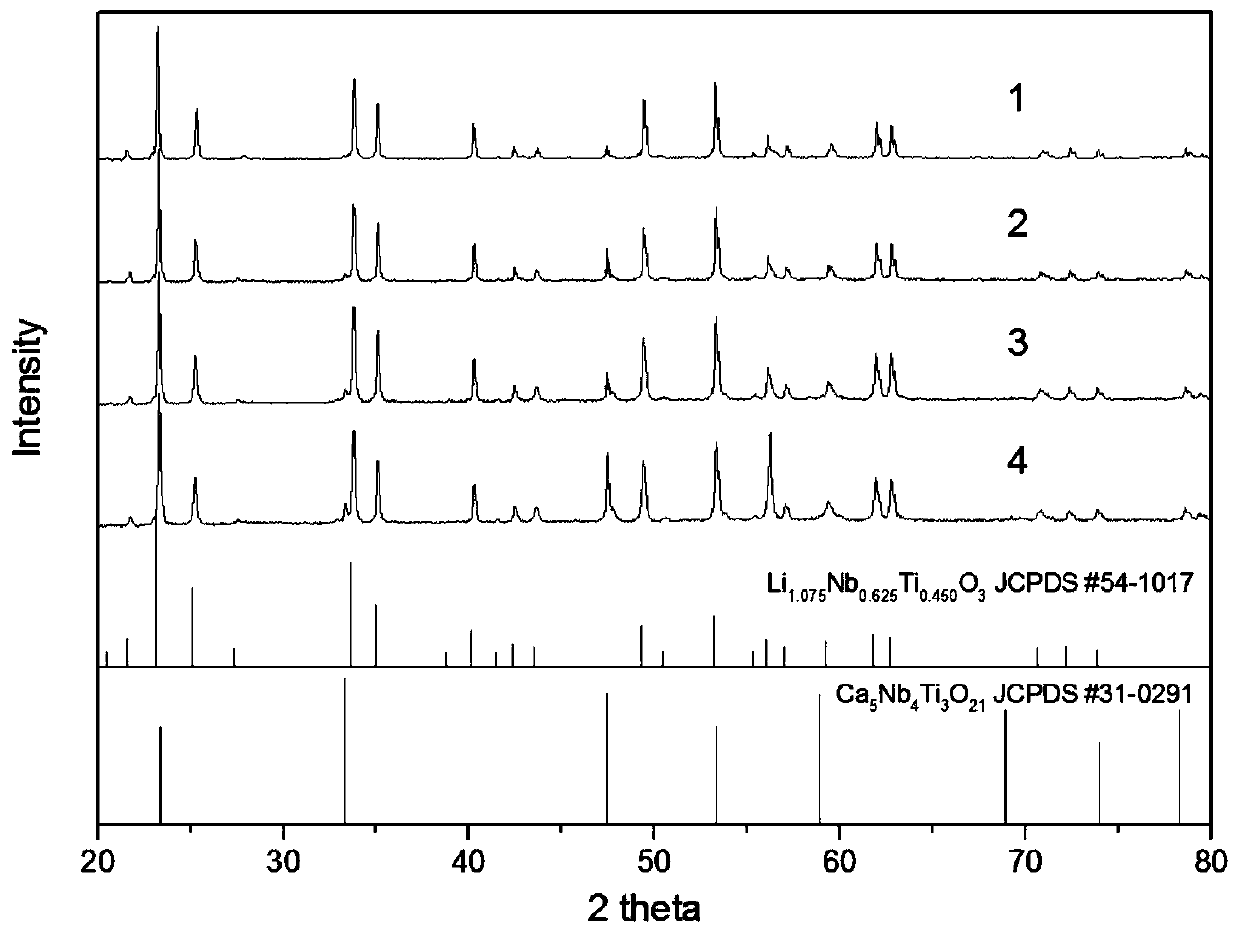

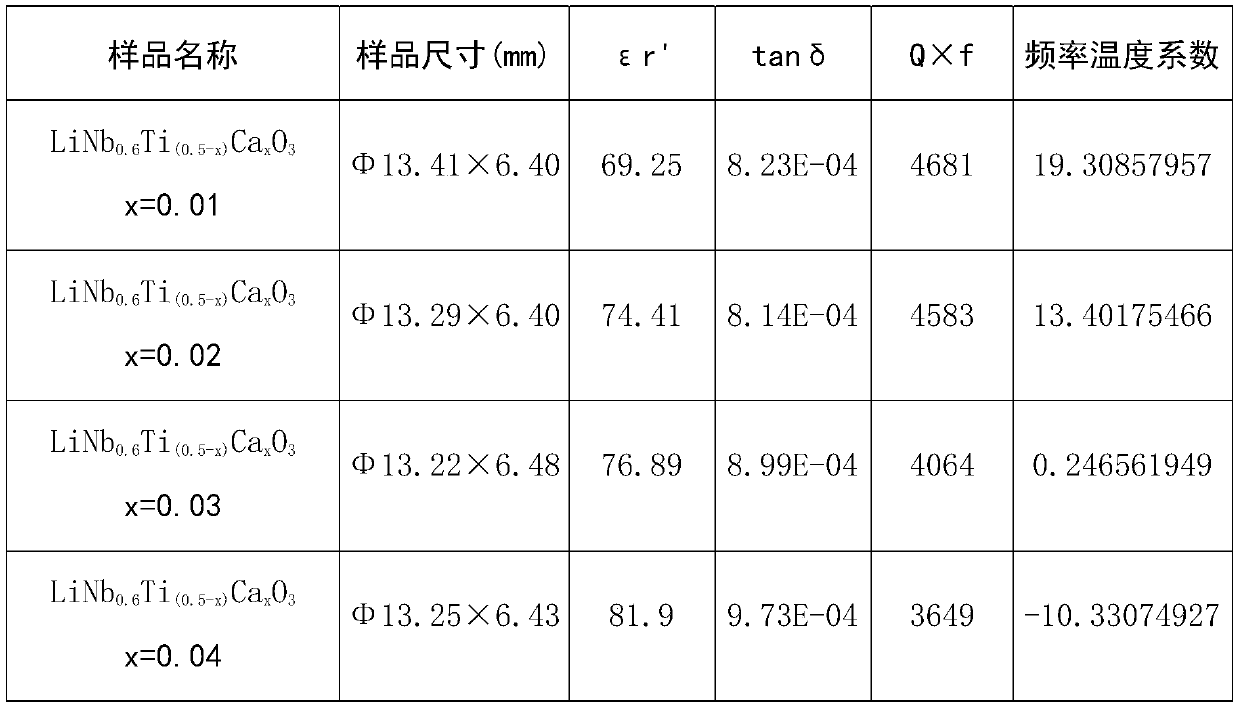

[0017] The preparation method includes the following steps:

[0018] Step 1, the raw material Li 2 CO 3 , Nb 2 O 5 , TiO 2 And CaCO 3 Powder according to chemical formula LiNb 0.6 Ti (0.5-x) Ca x O 3 (x=0.01-0.1) Ingredients, planetary ball milling with deionized water as medium for 5 hours, drying at 100℃ after taking out, sieving with 60 mesh screen, and then pre-burning at 870℃ for 4 hours to synthesize the main LNT raw material whose crystal phase is M phase;

[0019] Step 2. Use deionized water as the medium to mill the above LNT raw material planetary ball for 5 hours, take it out and dry it at 100°C, add PVA solution with 4% of it as a binder to granulate, press and shape, and finally at 1100°C Sintered in the atmosphere for 2 hours to prepare doped and modified LiNb 0.6 Ti (0.5-x) Ca x O 3 (x=0.01-0.1) Ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com