Lapping machine provided with high-speed rolling type bracket mechanism and applied to bio-based spun-bonding and hot-rolling line

A high-speed rolling, bio-based technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of anti-static net curtains affecting the service life, etc., to increase the life of the net curtain, uniform cloth surface without ripples, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

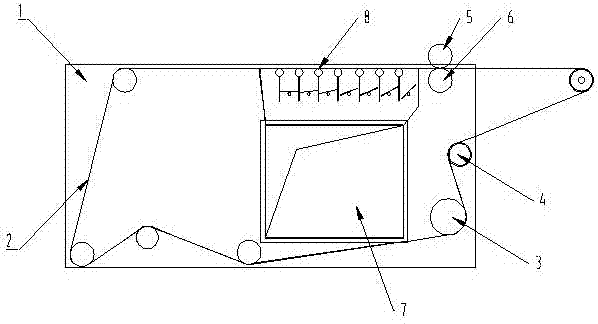

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] As shown in the figure, the present invention includes a net-laying machine frame 1, a mesh curtain 2, a transmission roller 3, a cloth guide roller 4, a pre-roller 5, a rubber lower roller 6, a suction bellows 7, and a grille on the suction bellows The top is provided with a horizontal rolling mechanism 8, and the rolling rod is made up of a bearing, a bearing seat, and a rolling rod, and a group of horizontal rolling mechanisms are arranged every 100-200mm in the width direction.

[0012] During production, when the net curtain of the netting machine is running at a line speed of 150 m / min, due to the addition of a lateral rolling mechanism, the friction and frictional resistance between the net curtain and the return air grid are reduced, energy is saved, costs are reduced, and improvements are made. production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com