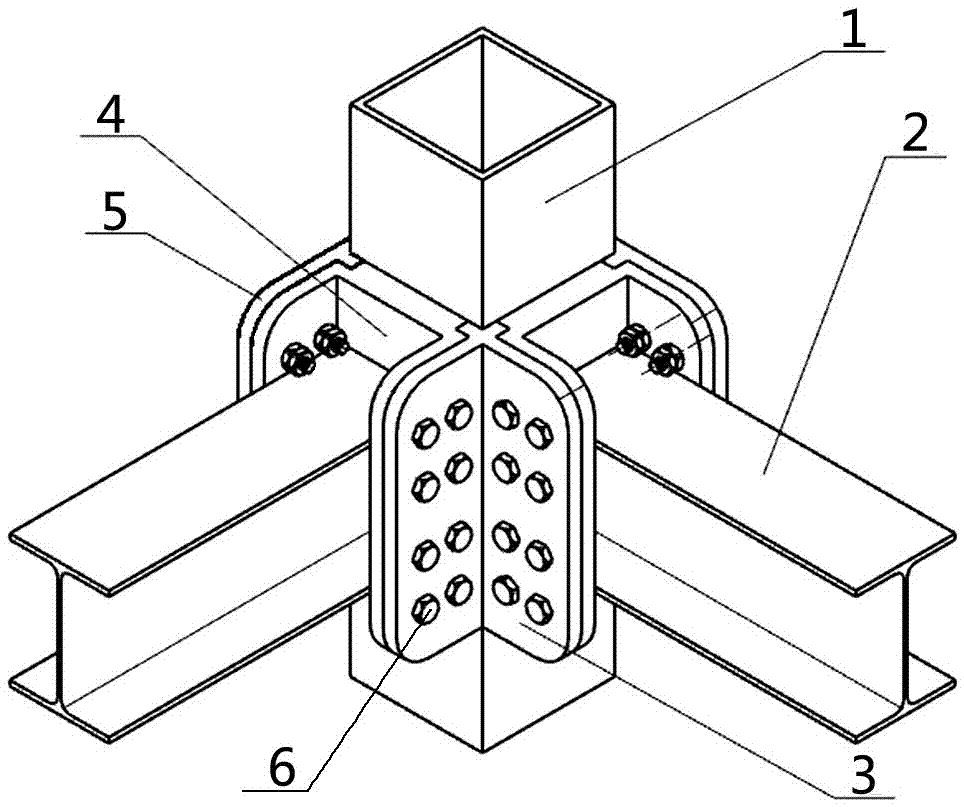

Corner beam column joint for square tubular column and H-shaped steel and assembled connection part and construction method for corner beam column joint

An H-beam assembly-type technology, which is applied in the direction of construction and building construction, can solve the problems of difficult control of assembly accuracy, failure to achieve productization, and high assembly accuracy requirements, so as to improve assembly efficiency, avoid slippage stress, and reduce construction. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

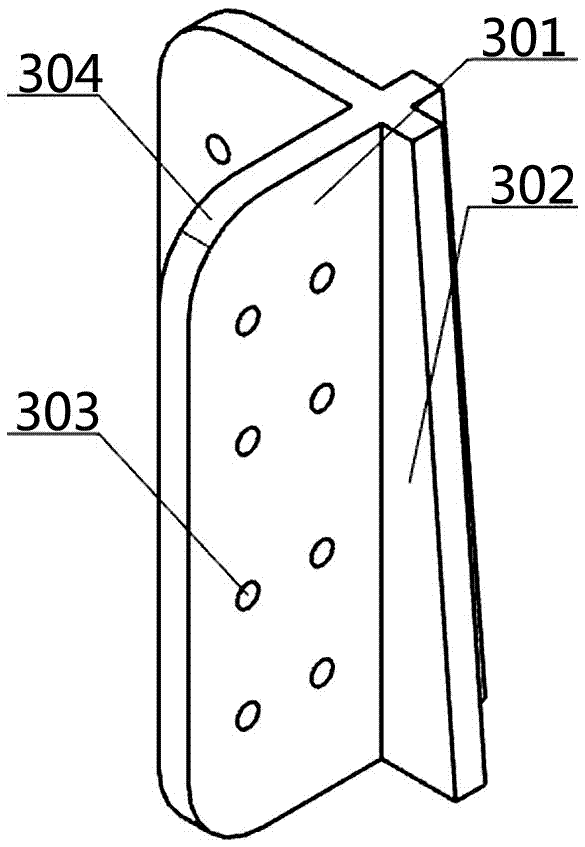

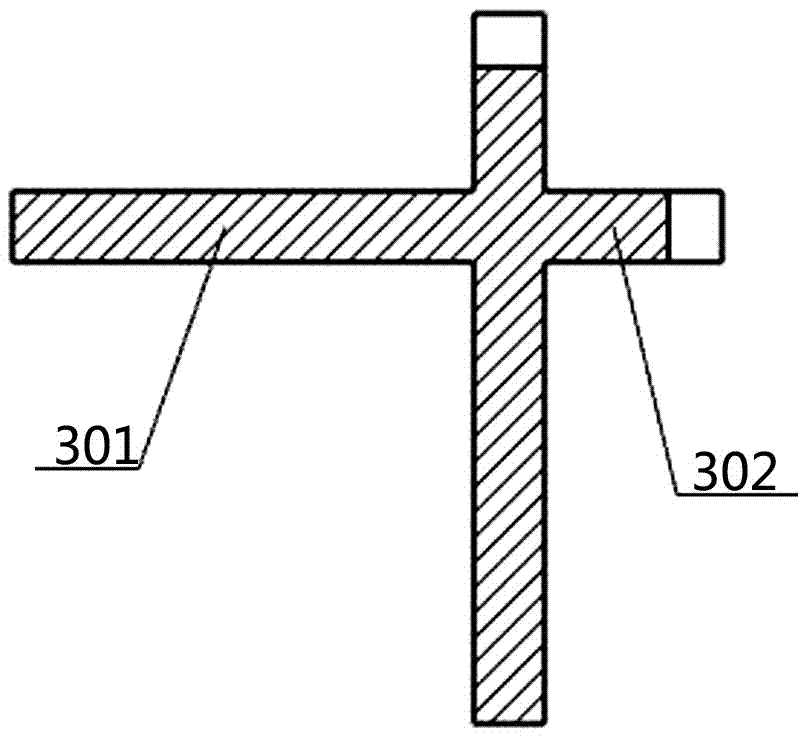

[0043] Hereinafter, embodiments of an angle beam-column joint between a square pipe column and an H-shaped steel, a fabricated connector and a construction method of the present invention will be described with reference to the accompanying drawings.

[0044] The examples described here are specific specific implementations of the present invention, and are used to illustrate the concept of the present invention. They are all explanatory and exemplary, and should not be construed as limiting the implementation of the present invention and the scope of the present invention. In addition to the embodiments described here, those skilled in the art can also adopt other obvious technical solutions based on the claims of the application and the contents disclosed in the description, and these technical solutions include adopting any obvious changes made to the embodiments described here. Replacement and modified technical solutions.

[0045] The accompanying drawings in this specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com