System and method for detecting leaks in generators

A technology of generators and detectors, which is applied in the direction of detecting the presence of fluid at the leak point, testing the tightness of the fluid by applying light, and measuring light by using an electric radiation detector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

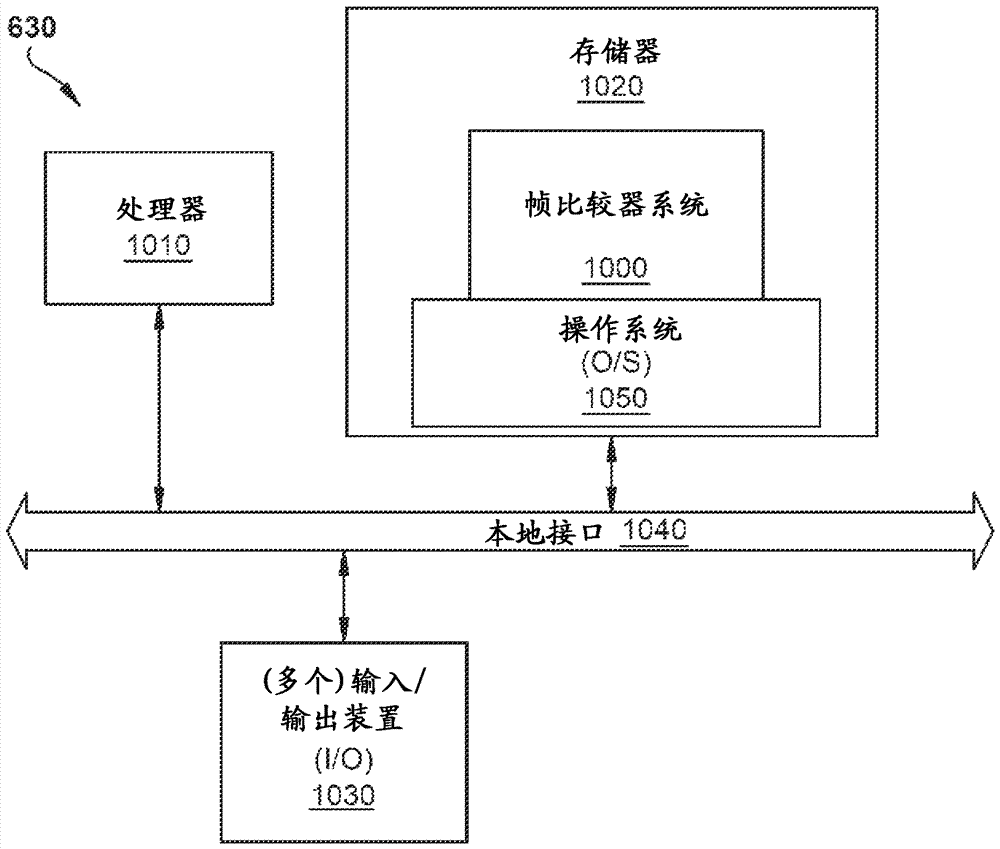

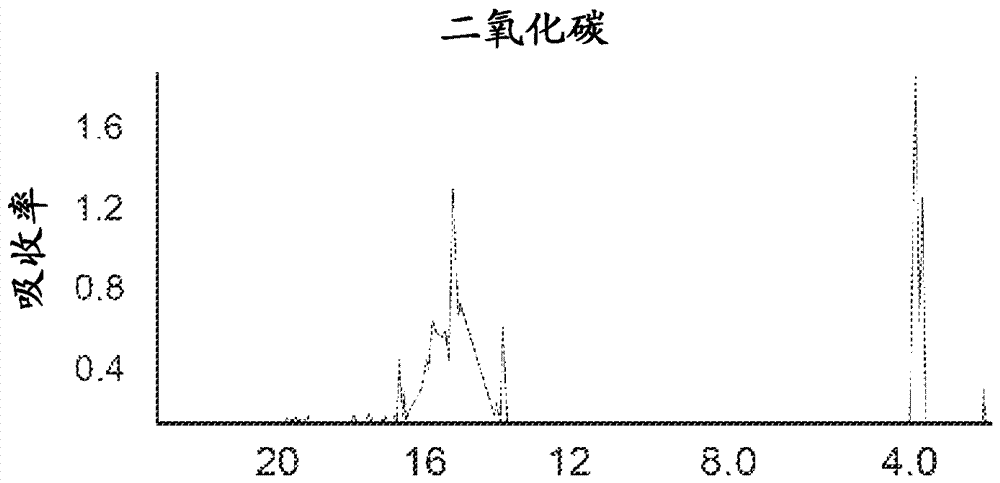

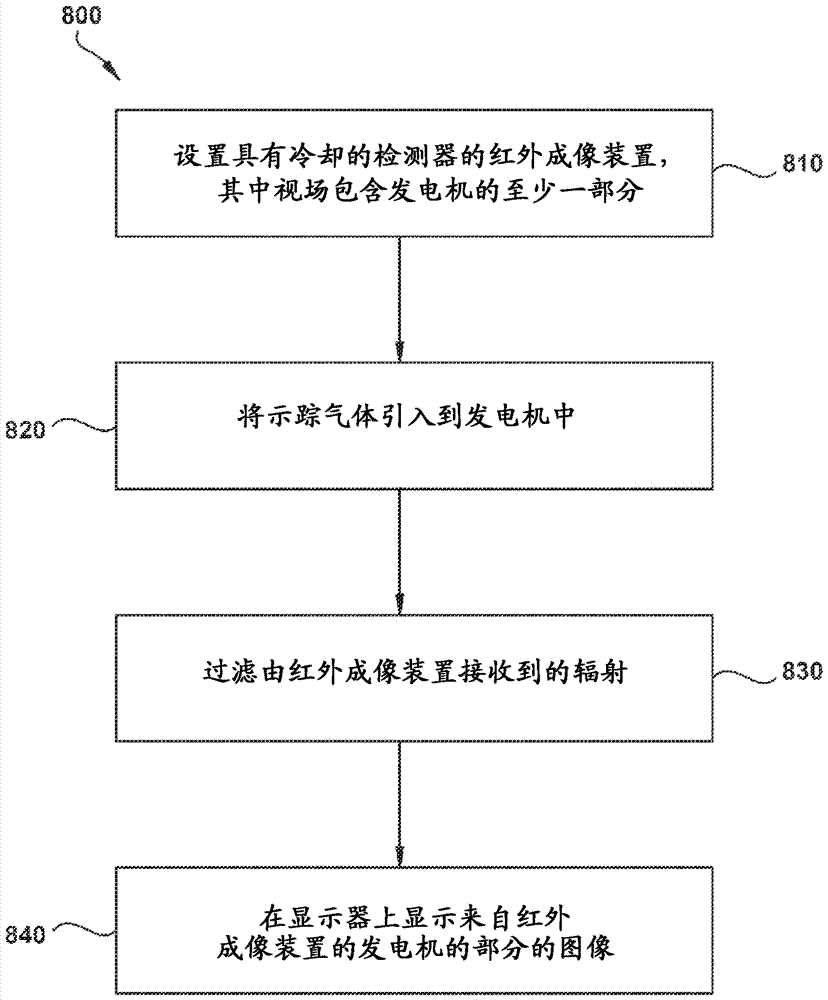

[0111] Aspects of the present disclosure include systems for detecting gas leaks in electric machines (eg, motors or generators) or turbines by introducing an environmentally safe and non-corrosive tracer gas into on-grid or off-grid machines. An infrared imaging device adapted to display images of the escaping tracer gas is provided.

[0112] figure 1 A schematic diagram of a system 10 for detecting gas leaks for use with a machine 15 is shown. Machine 15 may be an electric machine, hydrogen (H 2 ) cooled generators, direct liquid cooled generators, pressurized generators, pressurized gas cooled generators, or pressurized air cooled generators, motors, synchronous condensers, steam turbines or any machinery, sealed vessels, container or box. The phrase "leak detection" includes detecting a leak as well as locating the source of the leak. Leak detection system 10 includes infrared imaging device 20 capable of scanning most or a small portion of machine 15 . Infrared imagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com