A dust removal and heat dissipation structure for a switch cabinet

A technology of heat dissipation structure and switchgear, which is applied in the field of switchgear to achieve the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

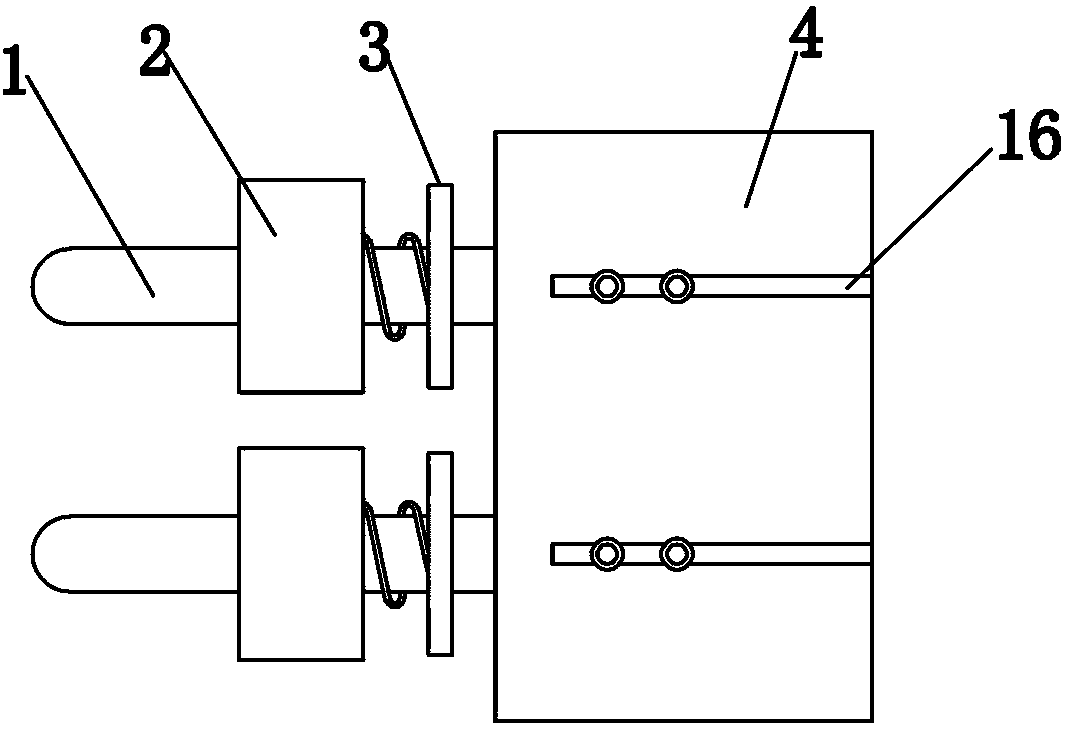

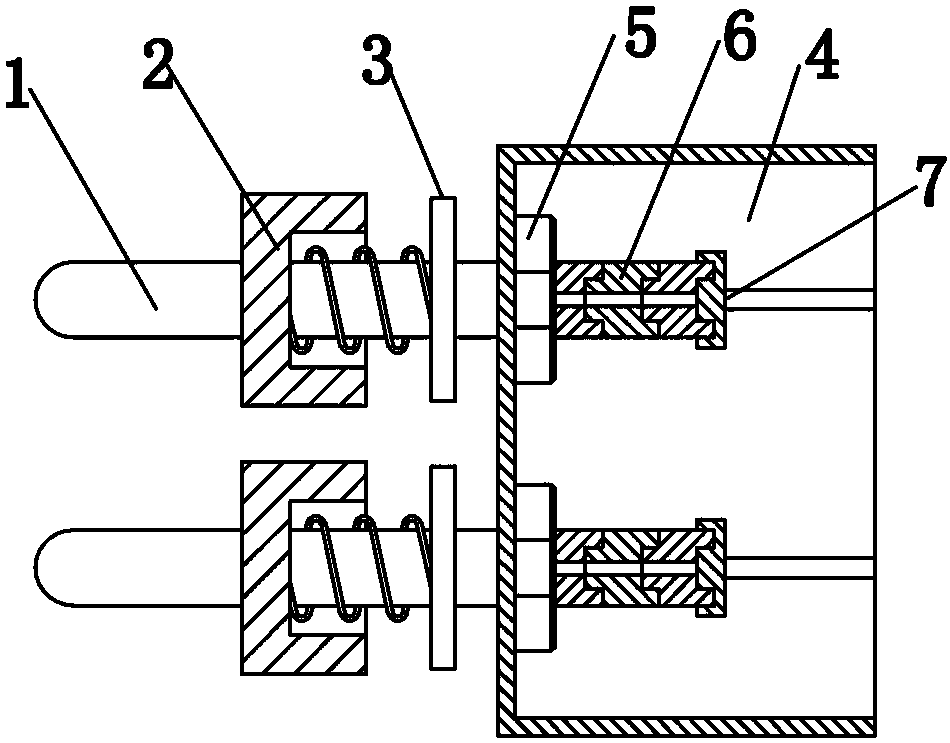

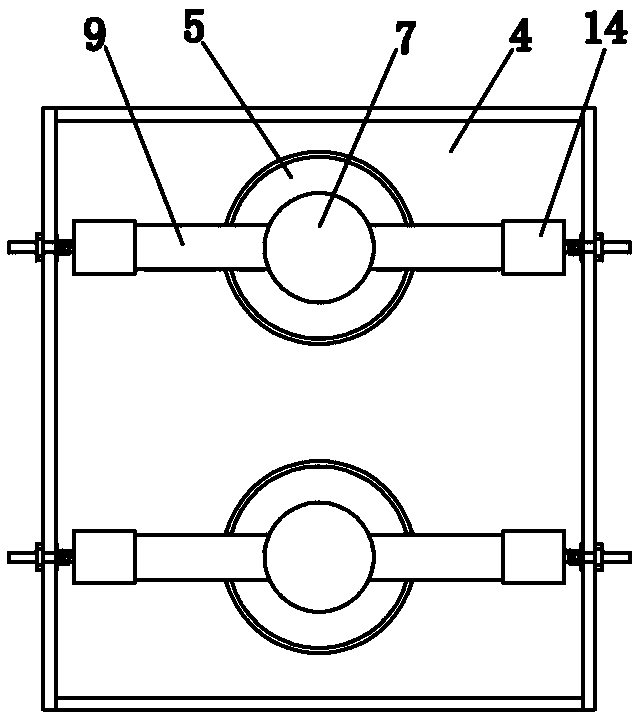

[0021] Depend on Figure 1 to Figure 9 Given, the present invention comprises a vent pipe and a filter box, the vent pipe 1 has through holes running through the left and right ends, one end of the vent pipe 1 is equipped with a stopper 2 and a sealing block 3, the stopper 2 is fixed on the vent pipe 1, sealed The block 3 can slide left and right on the vent pipe 1, and there is a spring set on the vent pipe 1 between the stopper 2 and the sealing block 3;

[0022] The other end of the ventilation pipe 1 passes through the side plate of the filter box 4 and is placed in the cavity of the filter box 4, and one end of the ventilation pipe 1 placed in the cavity of the filter box 4 is screwed with a nut 5 and placed in the cavity of the filter box 4 One end of the ventilation pipe 1 has a blind hole communicating with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com