Method and device for separating metal particles from rice flour

A technology for metal particles and rice flour, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as food insecurity, improve food hygiene and safety, improve water absorption and preparation, and improve fineness. and the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

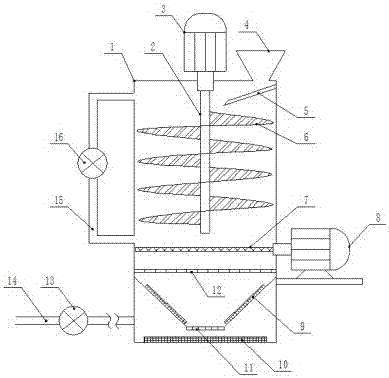

[0016] A device for separating metal particles from rice flour. A feeding hopper 4 is installed on the crushing box 1 of the device. A downwardly inclined feeding plate 5 is installed below the feeding hopper 4. A crushing shaft 2 is installed in the crushing box 1. Screw blade 6 is installed on the rotating shaft 2, one end of the crushing rotating shaft 2 is connected with the crushing motor 3, a vibrating screen 7 is installed below the crushing rotating shaft 2, the vibrating screen 7 is connected with the vibrating motor 8, and the crushing box 1 on one side of the vibrating screen 7 is A pumping pipe 15 is installed, and a pumping pump 16 is installed on the pumping pipe 15. The other end of the pumping pipe 15 is connected to the upper end of the crushing box 1. A primary filter 12 is installed below the vibrating screen 7, and a primary filter 12 is installed below the vibrating screen 7. A "V" shaped metal particle adsorber is installed, a primary electromagnet 9 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com