Appliance for clamping rod-like part during maintenance of nuclear power plant

A nuclear power plant, rod-aligning technology, applied in the direction of chucks, manipulators, claw arms, etc., can solve the problems of residual radiation harmful to the human body, inconvenient grabbing rod-shaped parts, etc., to achieve reduced contact, accurate and stable grabbing, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

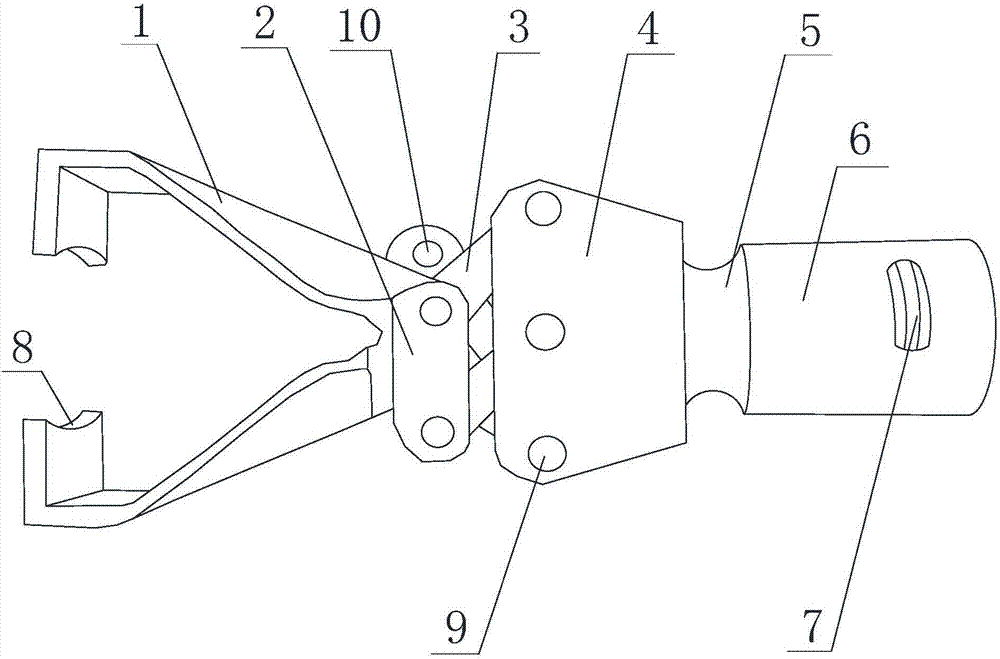

[0017] Such as figure 1 As shown, the device for clamping rod-shaped components during maintenance of nuclear power plants includes a connecting head 6 connected to a stretching mechanism, and the stretching mechanism is connected to a clamping member, which includes two clamping plates 1 , one end of the clamping plate 1 is connected to the stretching mechanism, and when the stretching mechanism is stretched, the clamping plate 1 moves toward the center line between the two clamping plates 1, and the end of the clamping plate 1 away from the stretching mechanism faces the two The central line direction between the clamping plates 1 is bent at 90°, and the end face has a concave arc groove 8, and the arc groove 8 completely runs through the end face. The stretching mechanism includes two mounting plates 4 with the same structure and arranged in parallel, one end of the connecting head 6 is arranged between the mounting plates 4 and fixed with the mounting plates 4, and three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com