Compact vehicle drive train

A transmission system and vehicle technology, which is applied to the transmission device, vehicle components, differential transmission device, etc., can solve the problems of increasing the complexity of the vehicle system, and achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

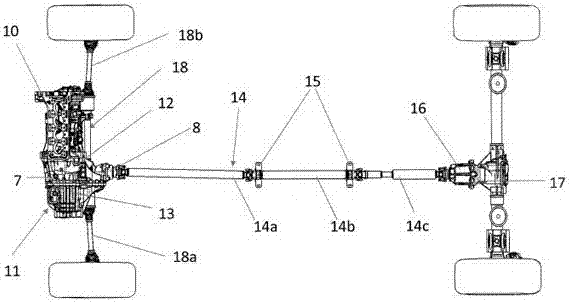

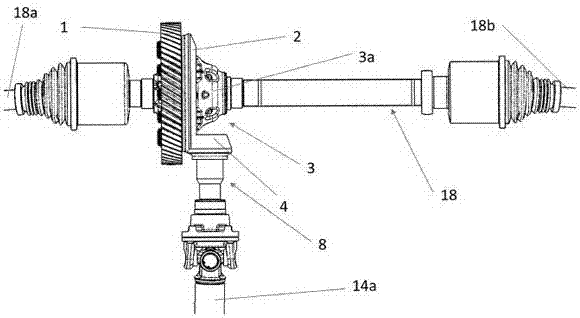

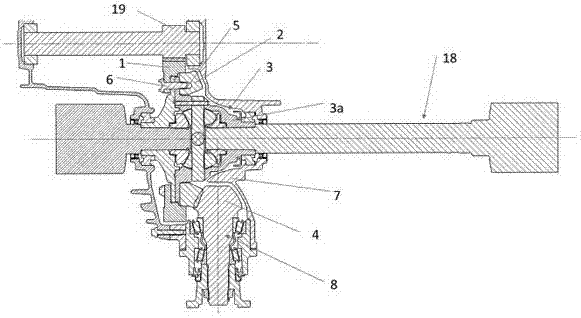

[0029] figure 1 It is a top view of the vehicle drive train assembly. figure 1 A power unit (engine) 10 connected to a manual transmission 11 is shown. The transmission 11 includes a transmission housing 7 which may include a differential housing 12 and a gear housing 13 which may be bolted together. The transmission 11 is connected to a differential 3 ( figure 2 shown). The differential 3 is connected to a power transmission unit 8 . The transmission 3 and the power transmission unit 8 will be described in more detail below.

[0030] The power transmission unit 8 is connected to the drive rod 14 through a universal joint. The drive rods 14 may include a front drive rod 14a, a central traction shaft 14b and a rear drive rod 14c. The drive rod 14 may also include one or more support bearings 15 . Said drive rod 14 is connected to a coupling 16 at the rear axle. Specifically, in the illustrated embodiment, coupling 16 is a smart lockable multi-plate clutch coupling. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com