Hygienic cotton baling machine for sanitary material manufacturing

A technology for sanitary materials and cotton wrapping machines, applied in packaging and other directions, can solve the problems of integration of sanitary materials production process, adverse effects on production, and reduced efficiency, and achieve the effects of reducing secondary pollution, reducing scrap rate, and accelerating production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

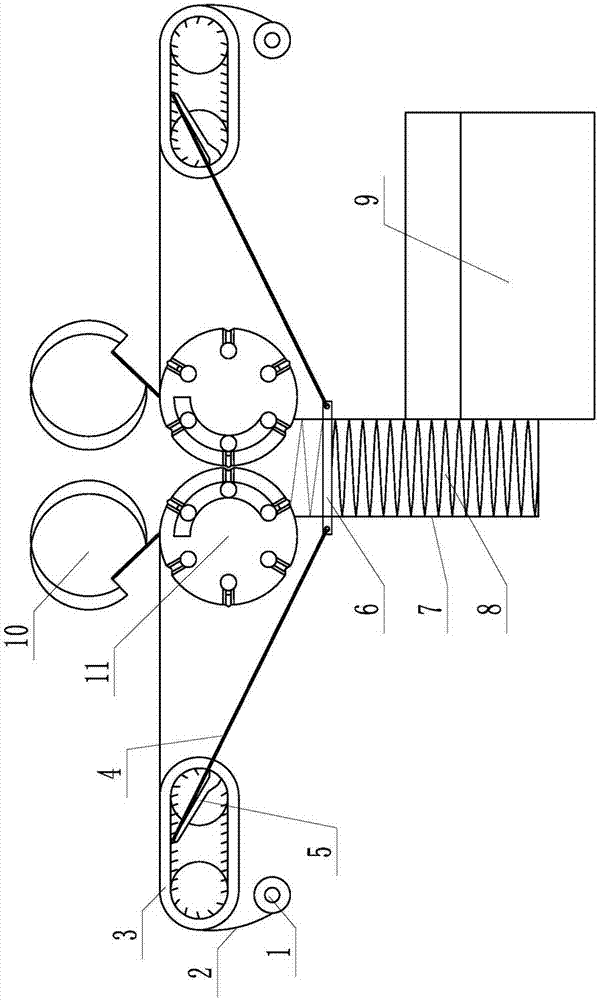

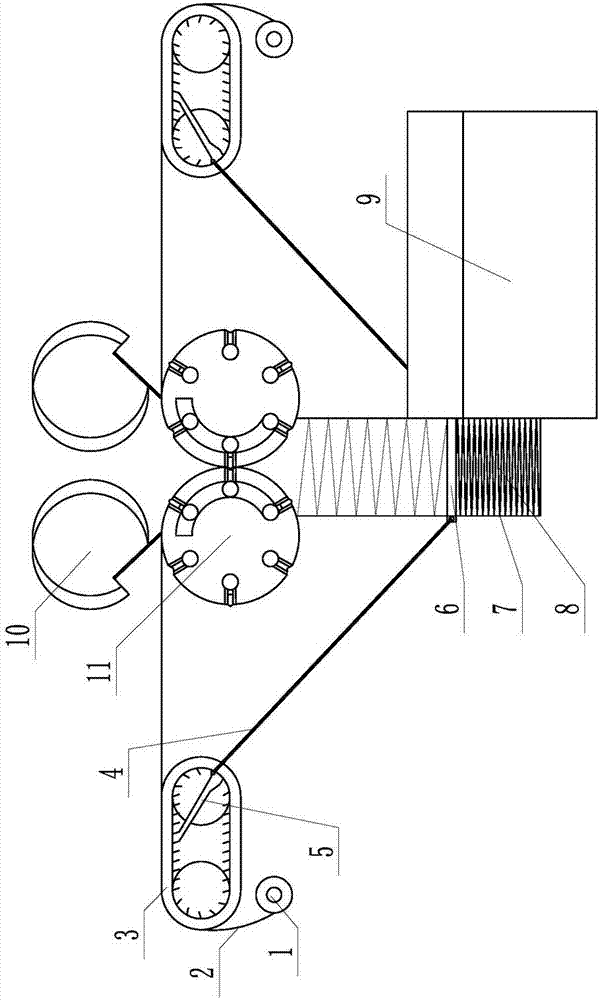

[0035] Embodiment 1: According to Figure 1 to Figure 9 As shown, the present invention includes a feeding mechanism, a stacking mechanism and a packaging mechanism. The feeding mechanism includes a feeding belt 3. There are a plurality of teeth 18 protruding obliquely from both sides of the feeding belt 3 in the same direction. The feeding mechanism is built with two ends connected respectively. The chute 5 on the upper and lower sides of the feeding belt 3 is slidably connected with a long rod 4 in the chute 5;

[0036] The stacking mechanism includes two groups of symmetrical cutting rollers and 10 folding rollers 11;

[0037] The bottom of the stacking mechanism is provided with a stacking trough 7 for storing the stacked sanitary materials 2. The stocking chute 7 is divided into upper and lower parts by the holding plate 6. The holding plate 6 slides up and down on the stacking chute 7, and the holding plate The two ends of 6 protrude from the outside of the storage tank...

Embodiment 2

[0046]Embodiment 2: On the basis of embodiment 1, feeding belt 3 is driven by two feeding wheels 17, and feeding belt 3 width is greater than feeding wheel 17, and tooth 18 is distributed in feeding belt 3 and stretches out the inner side of feeding wheel 17 two ends, and feeding Offer through-hole 20 on the wheel 17 axles, be provided with the air pipe 21 that communicates with air pump 19 in the through-hole 20, be densely covered with the first air hole 23 that a plurality of through suction pipe 24 and air pipe 21 communicate on the feeding wheel 17, feed belt 3 is densely covered with the second air hole 22 corresponding to the first air hole 23, and when the hygienic material 2 moves on the feed belt 3, the air pump 19 passes through the air pipe 21, the suction pipe 24, the first air hole 23 and the second air hole. The air hole 22 is a structure that absorbs the hygienic material 2 on the feeding belt 3 .

[0047] The width of feeding belt 3 is greater than feeding whe...

Embodiment 3

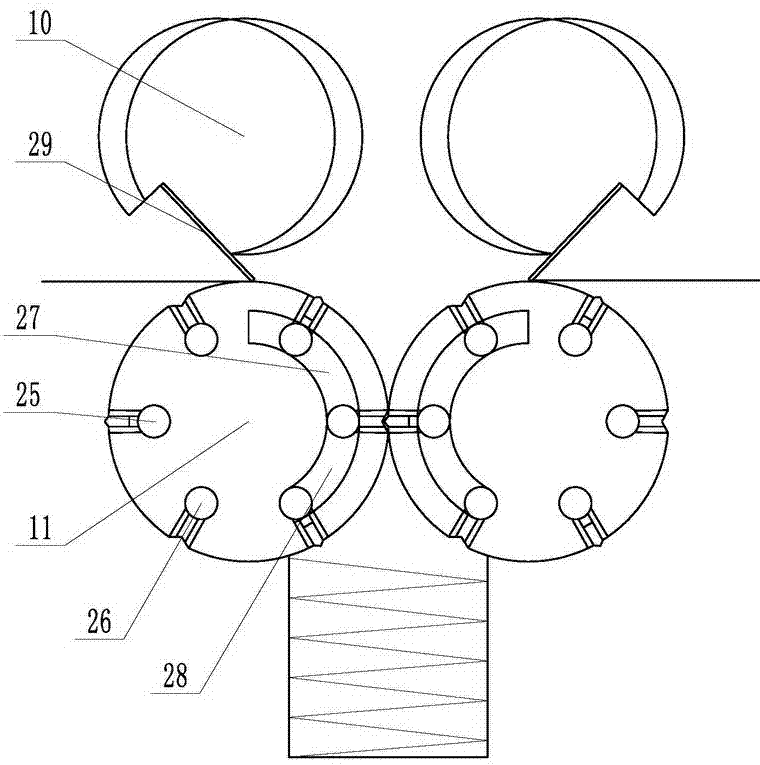

[0048] Embodiment 3: On the basis of Embodiment 1, the material cutting roller 11 is a fixed installation, and the cutting knife 29 with an oblique direction of 45° is fixed on the material cutting roller 10, and six feeding rollers arranged at intervals are evenly distributed on the folding material roller 11. The suction passage 25 and the folding suction passage 26, the feeding suction passage 25 communicates with the feeding air chamber 27 at one end of the folding roller 11, and the folding suction passage 26 communicates with the folding air chamber 28 at one end of the folding roller 11, The roll surface of the folding roller 11 communicates with the feeding suction channel 25 and the folding material suction channel 26 through small holes.

[0049] In this embodiment, the folding roller 11 is divided into a left folding roller and a right folding roller, and the feeding air chamber 27 and the folding air chamber 28 on the left folding roller and the right folding roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com