Preparation method of copybook golden brick writing board

A technology for writing boards and gold bricks, which is applied in the field of preparation of writing boards for writing gold bricks, can solve the problems of short cement setting time and limit the static processing of materials, and achieve compact, delicate and firm product quality, good filling effect, and fine particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

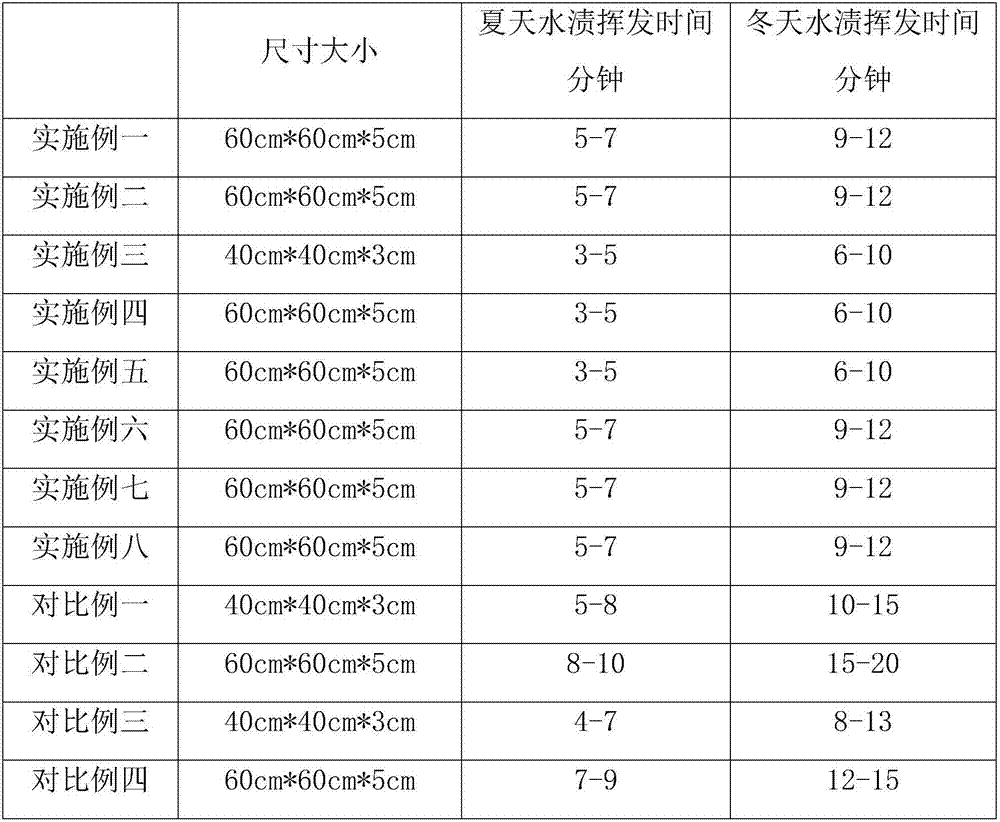

Embodiment 1

[0051] A kind of preparation method of Chinese calligraphy writing board, comprises the following steps:

[0052] The first step: make the main ingredients:

[0053] Take the lake mud at a depth of 10-12m under the lake, dry the lake mud and crush it into 1.0-1.2mm fine grains to obtain the main material;

[0054] The second step: with materials:

[0055] Materials comprising the following parts by weight: 80 parts of main ingredients, 10 parts of amorphous silicon dioxide, 30 parts of aluminum oxide, 15 parts of graphite, and 20 parts of water;

[0056] Mix the main ingredients with water and stir evenly at low speed, add graphite and then stir quickly for 1 hour, then add Al2O3 and amorphous silica, stir slowly for 0.5 hours, then stand at low temperature for 10 hours to obtain brick-making materials;

[0057] The third step: billet making:

[0058] Put the above-mentioned brick-making materials into the mold, the size of the green body is 60cm*60cm*5cm, and the pressure ...

Embodiment 2

[0064] A kind of preparation method of Chinese calligraphy writing board, comprises the following steps:

[0065] The first step: make the main ingredients:

[0066] Take the lake mud at a depth of 10-12m under the lake, dry the lake mud and crush it into 1.0-1.2mm fine grains to obtain the main material;

[0067] The second step: with materials:

[0068] Materials comprising the following parts by weight: 100 parts of main ingredients, 12 parts of amorphous silicon dioxide, 32 parts of aluminum oxide, 25 parts of graphite, and 30 parts of water;

[0069] Mix the main ingredients with water and stir evenly at a low speed, add graphite and stir quickly for 2 hours, then add aluminum oxide and amorphous silica, stir slowly for 1 hour, then stand at low temperature for 12 hours to obtain brick-making materials;

[0070] The third step: billet making:

[0071] Put the above-mentioned brick-making materials into the mold, the size of the green body is 60cm*60cm*5cm, and the pres...

Embodiment 3

[0077] A kind of preparation method of Chinese calligraphy writing board, comprises the following steps:

[0078] The first step: make the main ingredients:

[0079] Take the lake mud at a depth of 10-12m under the lake, dry the lake mud and crush it into 1.0-1.2mm fine grains to obtain the main material;

[0080] The second step: with materials:

[0081] Materials comprising the following parts by weight:

[0082] 92 parts of main ingredients, 12 parts of amorphous silicon dioxide, 30 parts of aluminum oxide, 18 parts of graphite, and 30 parts of water.

[0083] Mix the main ingredients with water and stir evenly at a low speed, add graphite and then stir quickly for 1 hour, then add aluminum oxide and amorphous silica, stir slowly for 0.5 hours, then stand at low temperature for 12 hours to obtain brick-making materials;

[0084] The third step: billet making:

[0085] Put the above-mentioned brick-making materials in the mold, the size of the green body is 40cm*40cm*3cm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com