High-sealing-performance medicinal synthetic-polyisoprene pad and preparation method thereof

A polyisoprene, high-sealing technology, applied in the field of high-sealing pharmaceutical synthetic polyisoprene gasket and its preparation, can solve problems such as liquid leakage, achieve fast vulcanization speed and increase resilience , the effect of smooth combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

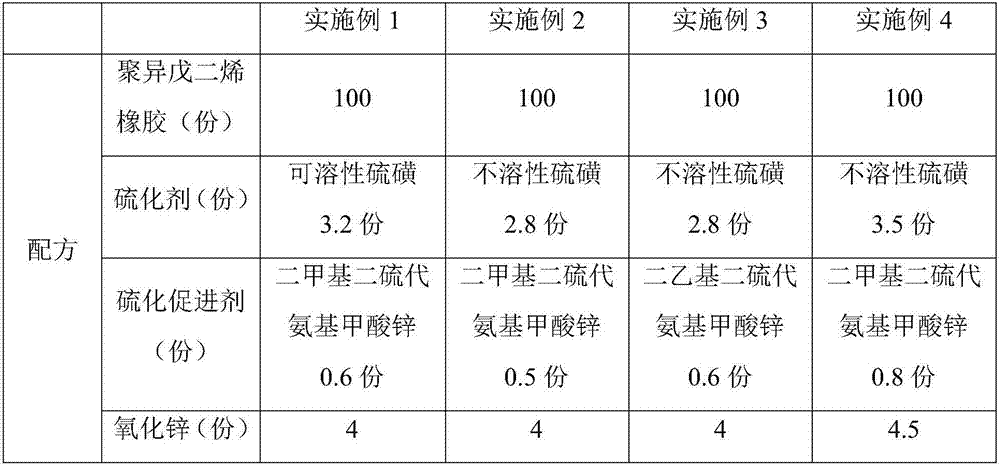

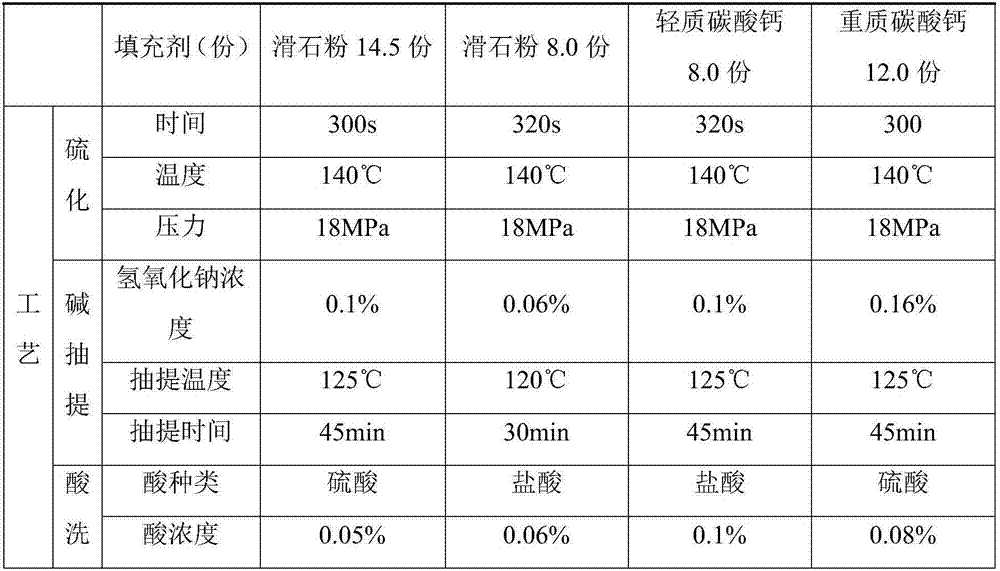

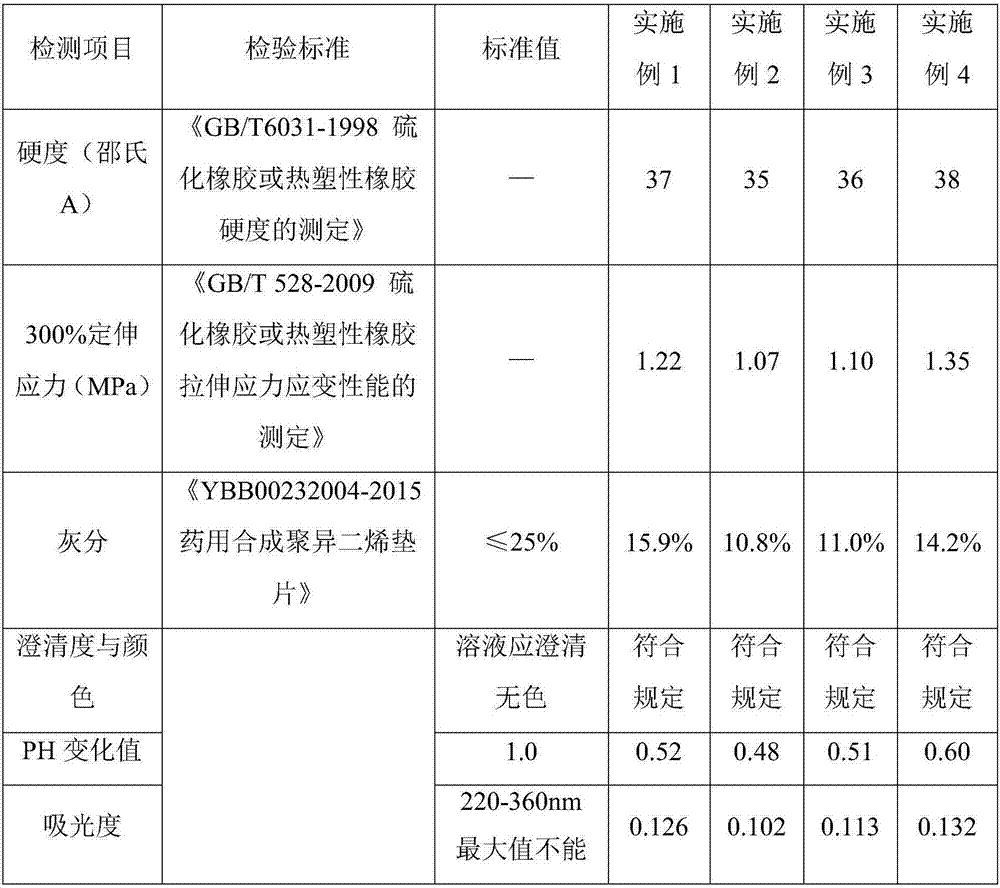

Embodiment 1

[0030] A high-tightness pharmaceutical synthetic polyisoprene gasket, comprising the following components by weight:

[0031] 100 parts of base rubber, 3.2 parts of soluble sulfur, 0.6 parts of zinc dimethyl dithiocarbamate, 4 parts of zinc oxide and 14.5 parts of talcum powder.

[0032] The preparation method of the above-mentioned high-tightness medicinal synthetic polyisoprene gasket comprises the following steps:

[0033] (1) Mixing of rubber materials: Put the basic rubber in the internal mixer for 3 minutes, add activator and filler to continue the internal mixing for 4 minutes, and then transfer the internally mixed rubber to the open mixer. If it causes scorching, it needs to be cooled on the open mill for 4 minutes, and finally add the vulcanizing agent and vulcanization accelerator, and start the refining for 6 minutes.

[0034] (2) Sheeting: After the mixed rubber material is parked for 4 hours, it is made into a 2mm thick sheet through a roller press;

[0035] (3...

Embodiment 2

[0042] A high-tightness pharmaceutical synthetic polyisoprene gasket, comprising the following components by weight:

[0043] 100 parts of base rubber, 2.8 parts of insoluble sulfur, 0.5 parts of zinc dimethyl dithiocarbamate, 4 parts of zinc oxide and 8 parts of talcum powder.

[0044] The preparation method of the above-mentioned high-tightness medicinal synthetic polyisoprene gasket comprises the following steps:

[0045] (1) Mixing of rubber materials: put the basic rubber in the internal mixer for 4 minutes, add activator and filler to continue the internal mixing for 5 minutes, and then transfer the internally mixed rubber to the open mixer. If it causes scorching, it needs to be cooled on the open mill for 4 minutes, and finally add the vulcanizing agent and vulcanization accelerator, and start the refining for 6 minutes.

[0046] (2) Sheeting: After the mixed rubber material is parked for 4 hours, it is made into a 2mm thick sheet through a roller press;

[0047] (3)...

Embodiment 3

[0054] A high-tightness pharmaceutical synthetic polyisoprene gasket, comprising the following components by weight:

[0055] 100 parts of base rubber, 2.8 parts of insoluble sulfur, 0.6 parts of zinc diethyldithiocarbamate, 4 parts of zinc oxide and 8 parts of light calcium carbonate.

[0056]The preparation method of the above-mentioned high-tightness medicinal synthetic polyisoprene gasket comprises the following steps:

[0057] (1) Mixing of rubber materials: Put the basic rubber in the internal mixer for 4 minutes, add activator and filler to continue the internal mixing for 6 minutes, and then transfer the internally mixed rubber to the open mixer. If it causes scorching, it needs to be cooled on the open mill for 3 minutes, and finally add the vulcanizing agent and vulcanization accelerator, and start the kneading for 6 minutes. After two times, the tablet is removed to complete the rubber mixing;

[0058] (2) Sheeting: After the mixed rubber material is parked for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com