Indigo dye preparation method and cloth dyeing method

A dye and indigo technology, applied in the field of dyeing cloth, can solve the problems of low adhesion of indigo dye, not bright color, easy color fading of the fabric, etc., and achieve the effect of bright color, improved adhesion strength and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

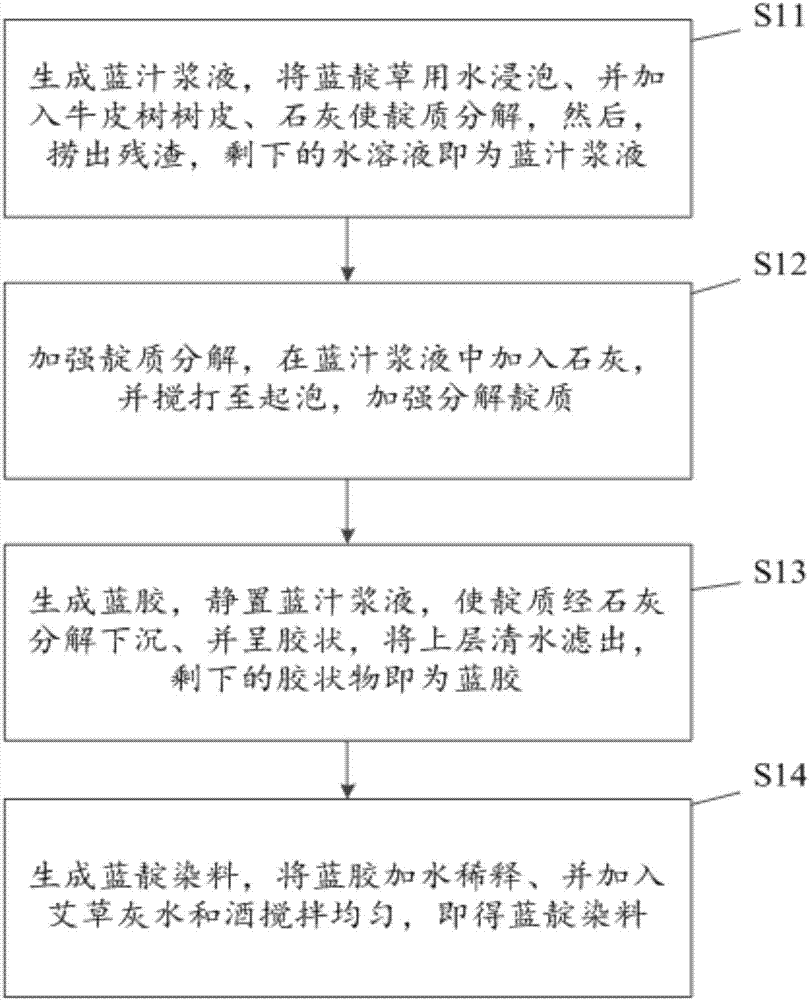

[0038] figure 1 For the flow chart of the indigo dye preparation method that the first embodiment of the present invention provides, please refer to figure 1 .

[0039] The present embodiment provides a kind of indigo dye preparation method, and described indigo dye preparation method comprises the following steps:

[0040] S11: To generate blue juice slurry, soak the indigo grass in water, add cowhide tree bark and lime to decompose indigo, then remove the residue, and the remaining aqueous solution is the blue juice slurry.

[0041] In the step of generating the blue juice slurry, the weight relationship of each component is: 50 parts of indigo, 2.5 parts of cowhide bark, 1.5 parts of lime, and 75 parts of water. Preferably, the time for soaking the indigo grass in water is 10 to 25 days.

[0042] S12: To strengthen the decomposition of indigo, add lime to the blue juice slurry, and beat until foaming, to strengthen the decomposition of indigo.

[0043] The step of stren...

no. 2 example

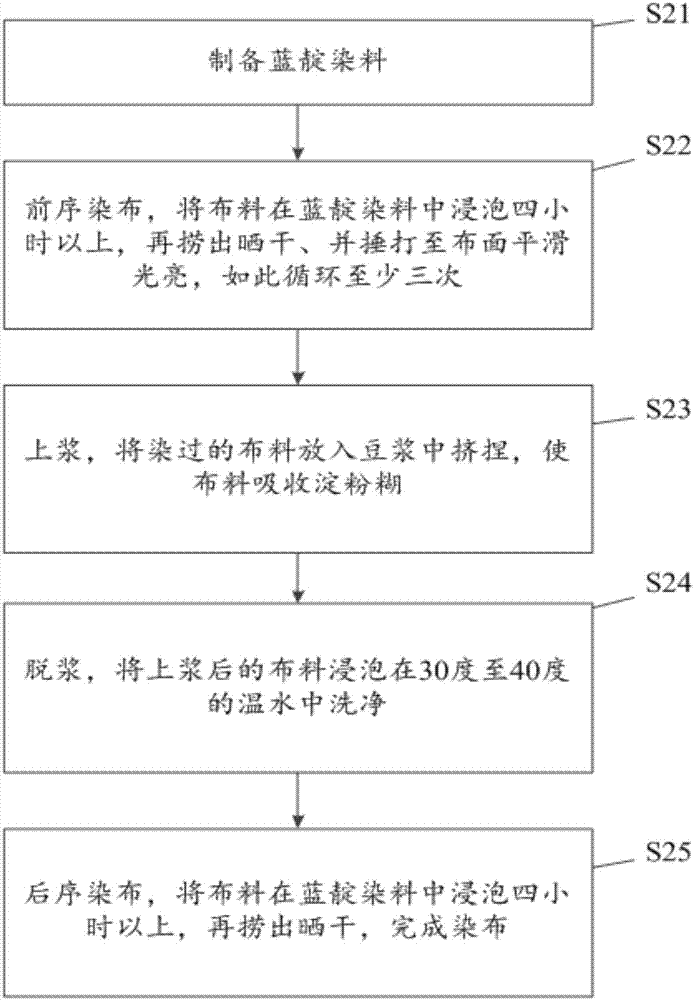

[0051] figure 2 For the flow chart of the cloth dyeing method that the second embodiment of the present invention provides, please refer to figure 2 .

[0052] The cloth dyeing method that present embodiment provides comprises the following steps:

[0053] S21: preparing indigo dye.

[0054] Specifically include the following steps:

[0055] Generate blue juice slurry, soak 50 parts by weight of indigo with 75 parts by weight of water, add 2.5 parts by weight of cowhide bark, 1.5 parts by weight of lime to decompose indigo, then pull out the residue, and the remaining The aqueous solution is the blue juice slurry.

[0056] To strengthen the decomposition of indigo, add lime to the blue juice slurry and beat until foamy to strengthen the decomposition of indigo.

[0057] Blue gum is produced, and the blue juice slurry is left to stand for 20 to 30 days, so that the indigo decomposes and sinks through lime, and becomes gelatinous, and the upper layer of clear water is filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com