Recycled aggregate total pervious concrete pavement structure and construction method thereof

A technology of permeable concrete and recycled aggregate, which can be applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problem of restricting the popularization and application of recycled aggregate permeable concrete pavement structure, and the wear resistance of recycled aggregate permeable concrete can not meet the requirements Pavement concrete and other problems, to avoid soil loss, reduce heat island effect, and alleviate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

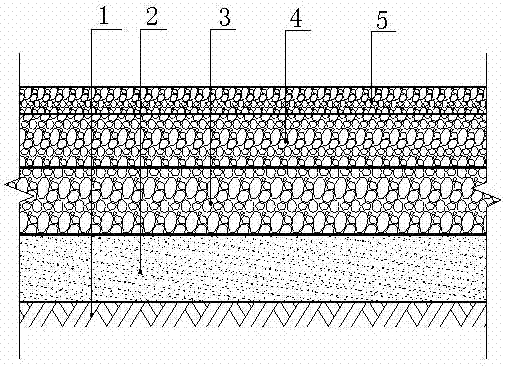

[0027] See figure 1 . The recycled aggregate fully permeable concrete pavement structure provided by the invention includes a permeable cushion 2, a permeable base 3, a permeable surface 4, and a permeable cover 5 laid from bottom to top on the soil foundation 1; the permeable cushion 2. Natural crushed stone is used, the thickness of which is 100-200mm; the permeable base layer 3 is made of recycled aggregate permeable concrete, the maximum particle size of the aggregate is less than 16mm, and the laying thickness is not less than 150mm; the permeable surface layer 4 is made of recycled aggregate Permeable concrete, the maximum particle size of the aggregate is less than 16.0mm, the laying thickness is 90-120mm, and the water permeability coefficient is greater than the permeable cover layer; the permeable cover layer 5 is configured with natural aggregates such as hard, durable and clean granite For permeable cement concrete, the maximum particle size of the aggregate is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com