A non-explosion-proof trackless transportation method for high gas and gas outburst tunnels

A technology for gas prominent, trackless transportation, applied in gas emission, underground transportation, transportation and packaging, etc., can solve the problems of high energy consumption, high cost, difficult to popularize and apply, and achieve less labor, cost reduction, and ventilation energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

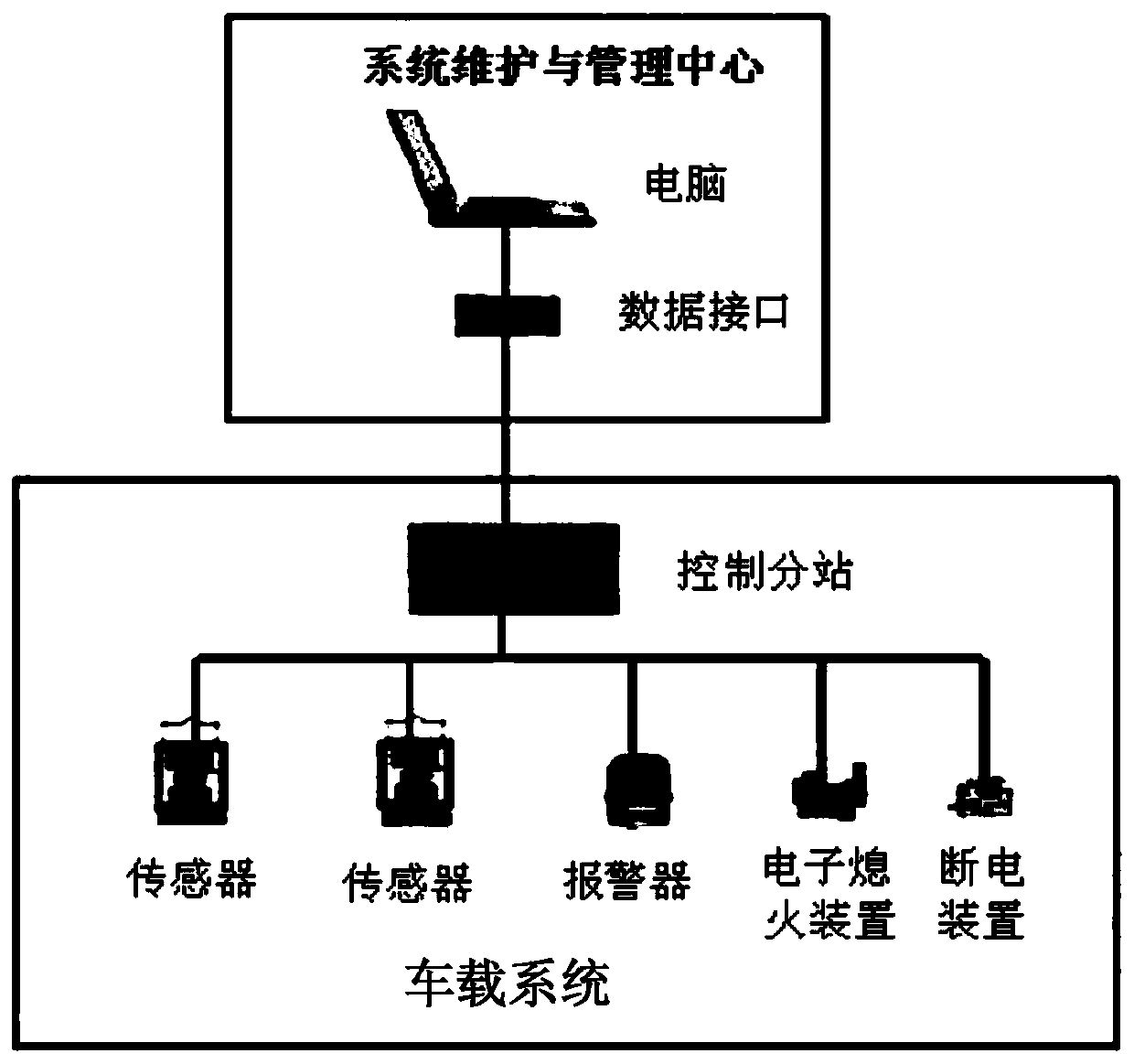

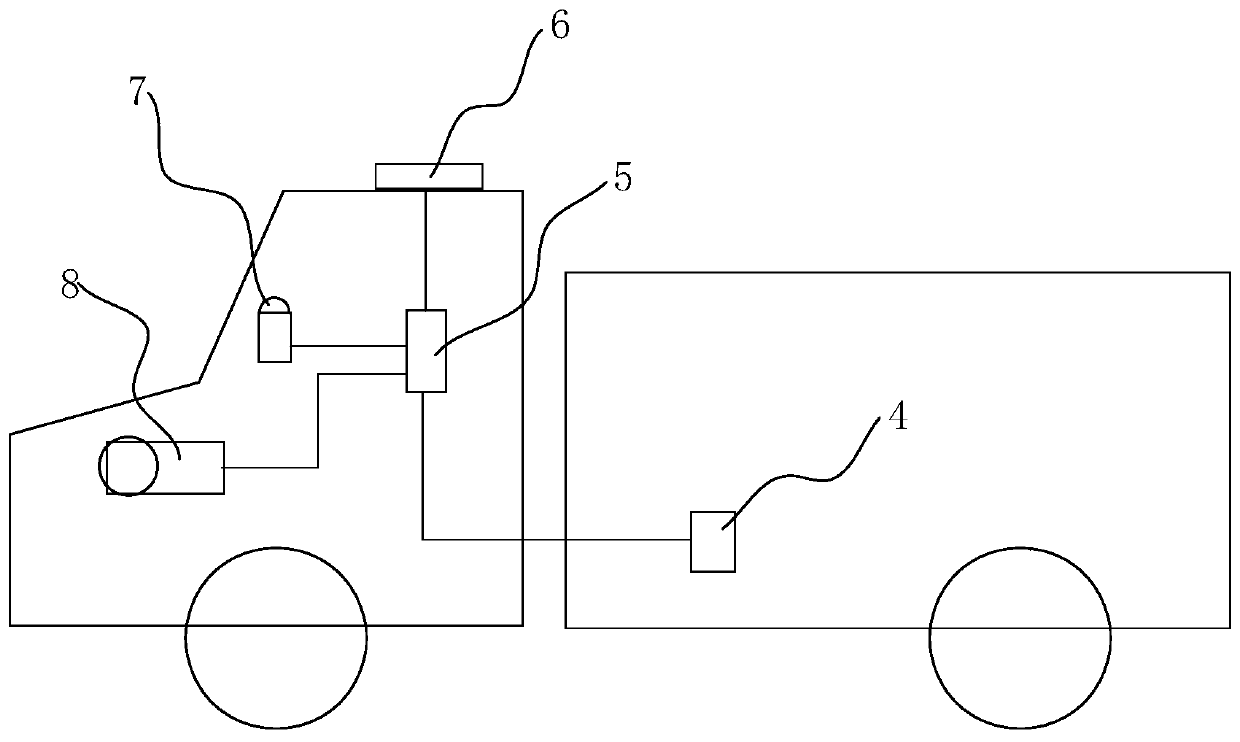

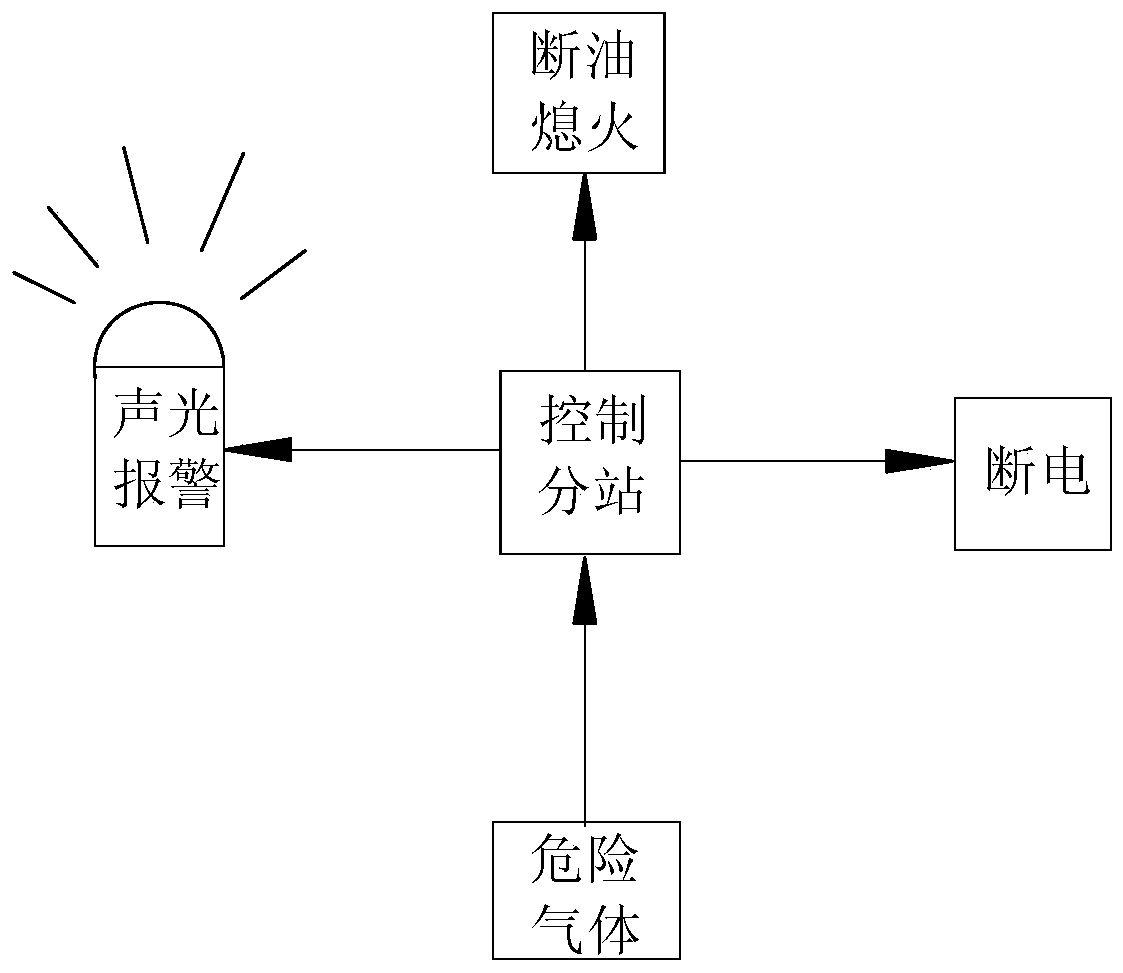

[0049] The non-explosion-proof trackless transportation method for high gas and gas outburst tunnels of the present invention is carried out through comprehensive utilization of the following steps: tunnel energy-saving ventilation step, tunnel coal seam and gas advance prediction step, gas outburst coal seam gas drainage anti-outburst treatment step, gas outburst tunnel The construction steps of uncovering the coal, the steps of predicting and controlling the amount of gas emission, the steps of gas monitoring and monitoring during tunnel construction, and the steps of locking tile cars in the gas tunnel according to the signals obtained from the steps of tunnel gas detection and monitoring. Even if the above-mentioned steps are all combined using the existing technology, the present invention can avoid the use of explosion-proof equipment, reduce the weight of the equipment, and significantly reduce both the equipment purchase cost, the use cost and the energy consumption. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com