Vertical vibration reducing and vibration isolating support and working method thereof

A vibration reduction and vibration isolation, vertical technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the limitations, poor compressive bearing capacity, vertical vibration reduction and vibration isolation function Affected by the structure and other issues, it achieves the effect of good air tightness, good vibration reduction and vibration isolation effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention will be further described.

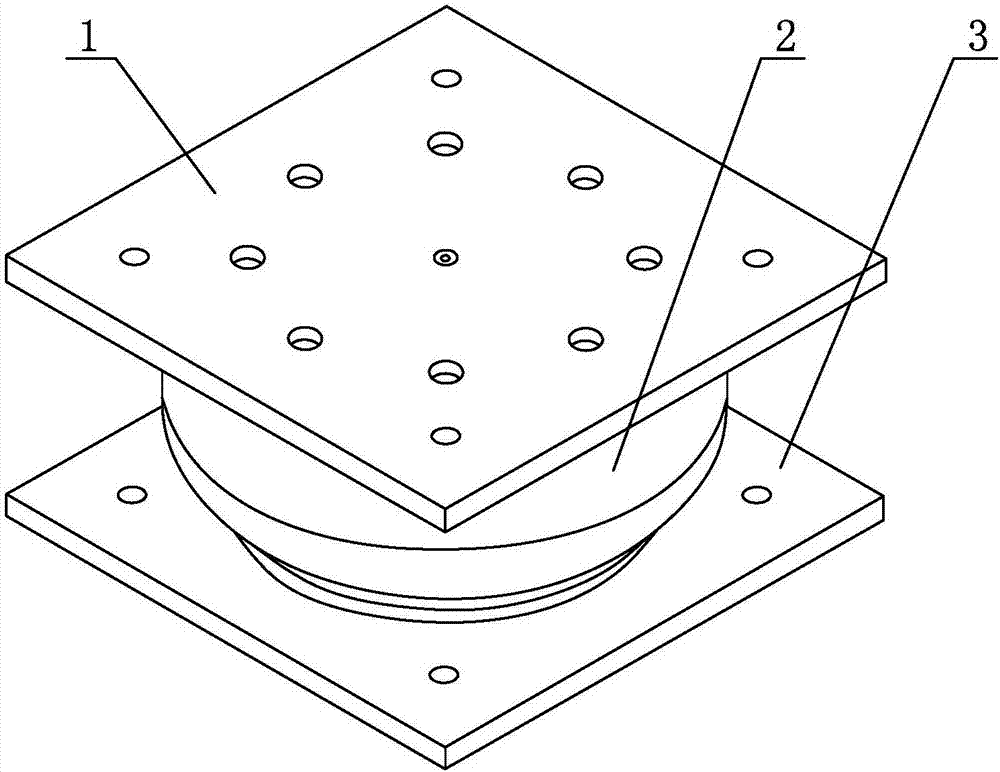

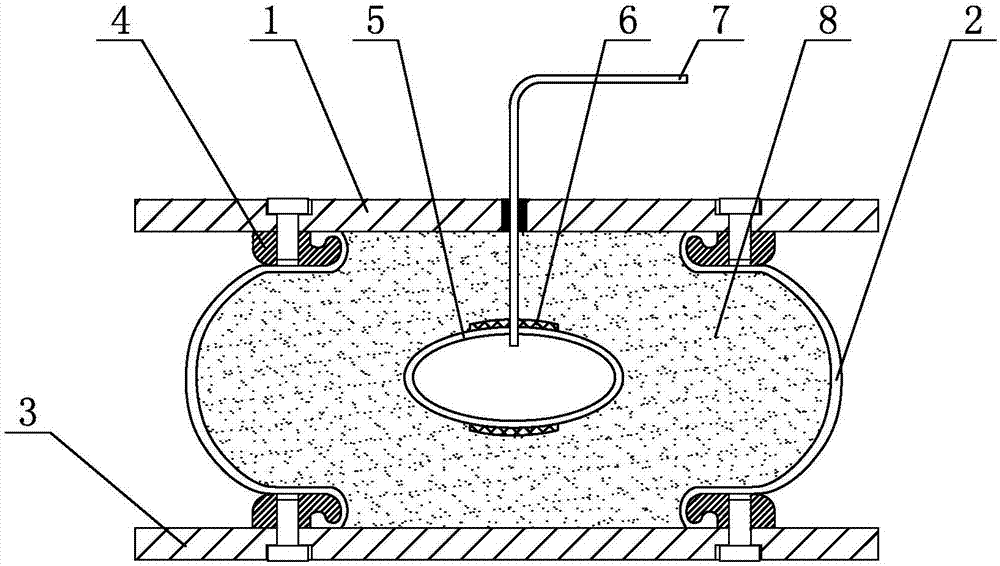

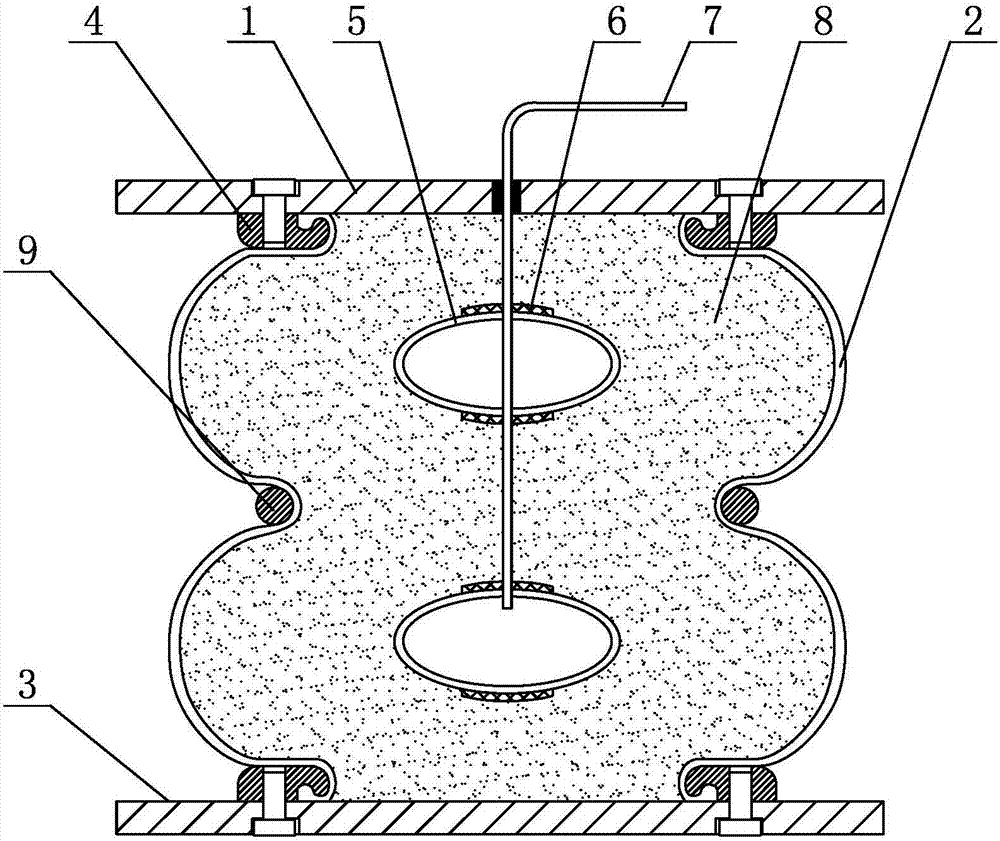

[0021] Such as figure 1 , figure 2 As shown, the vertical vibration-reducing vibration-isolation support includes an upper sealing plate 1, a pressure-bearing capsule 2, a lower sealing plate 3, a positioning flange 4, an airbag 5, and solid particles 8. The side of the pressure-bearing capsule is an arc-shaped surface , the upper and lower ends of the pressure-bearing capsule are respectively provided with positioning flanges, and the upper and lower positioning flanges are respectively fastened to the corresponding upper and lower sealing plates through the upper and lower positioning flanges and bolts. The inner cavity of the pressure-bearing capsule is provided with an airbag, which is filled with gas such as air or nitrogen, and the cavity formed between the inner cavity of the pressure-bearing capsule and the outer wall of the airbag is densely filled with solid part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com