Welding seam texture tissue nondestructive testing system

A non-destructive testing and textured tissue technology, which is applied in the direction of measuring devices, polarization-influenced characteristics, and material analysis through optical means, and can solve problems such as high requirements, poor picture clarity, and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core of the present invention is to provide a non-destructive testing system for weld texture structure, which can detect the quality of the weld without damaging the weld to be tested, and is applicable to welds with low magnetic permeability.

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the non-destructive testing system for weld texture structure of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

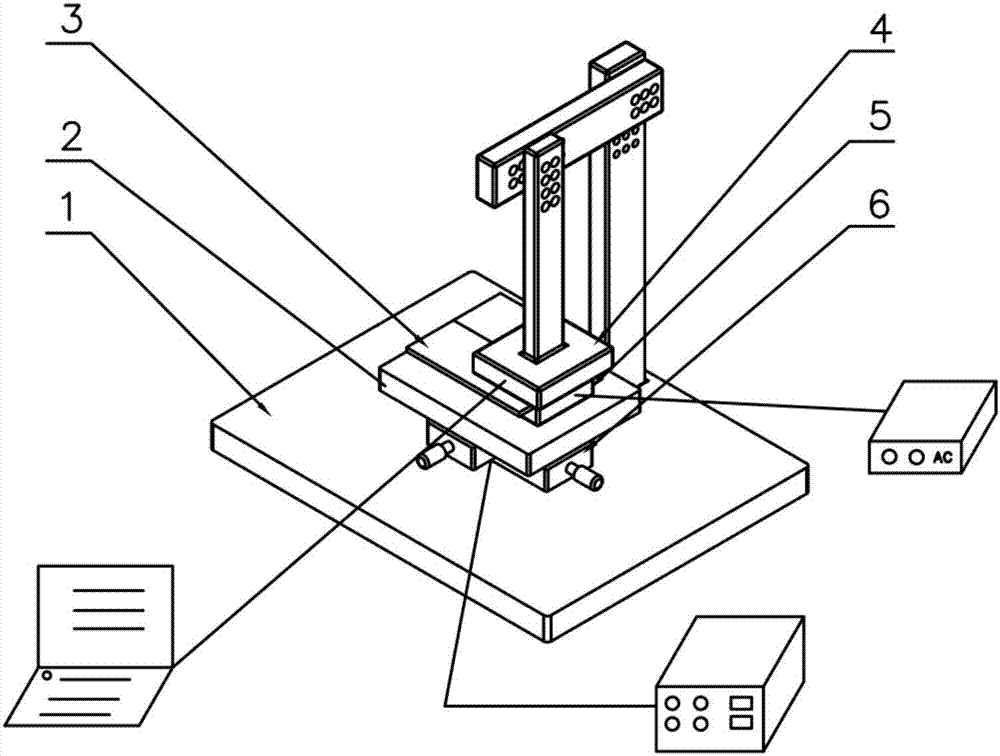

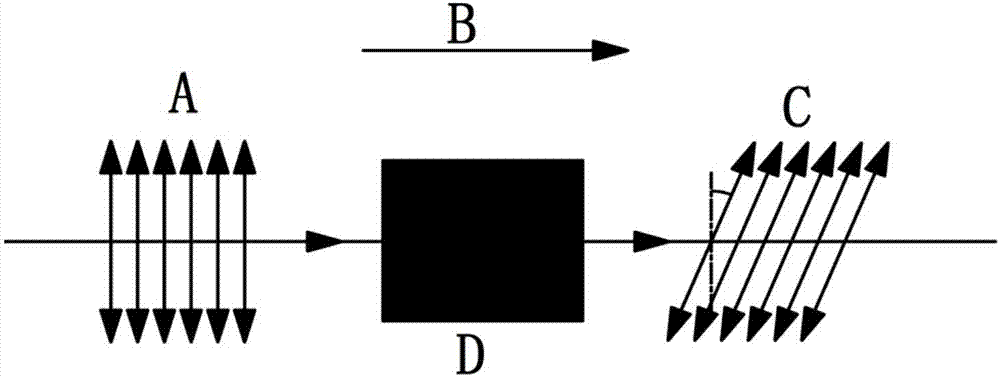

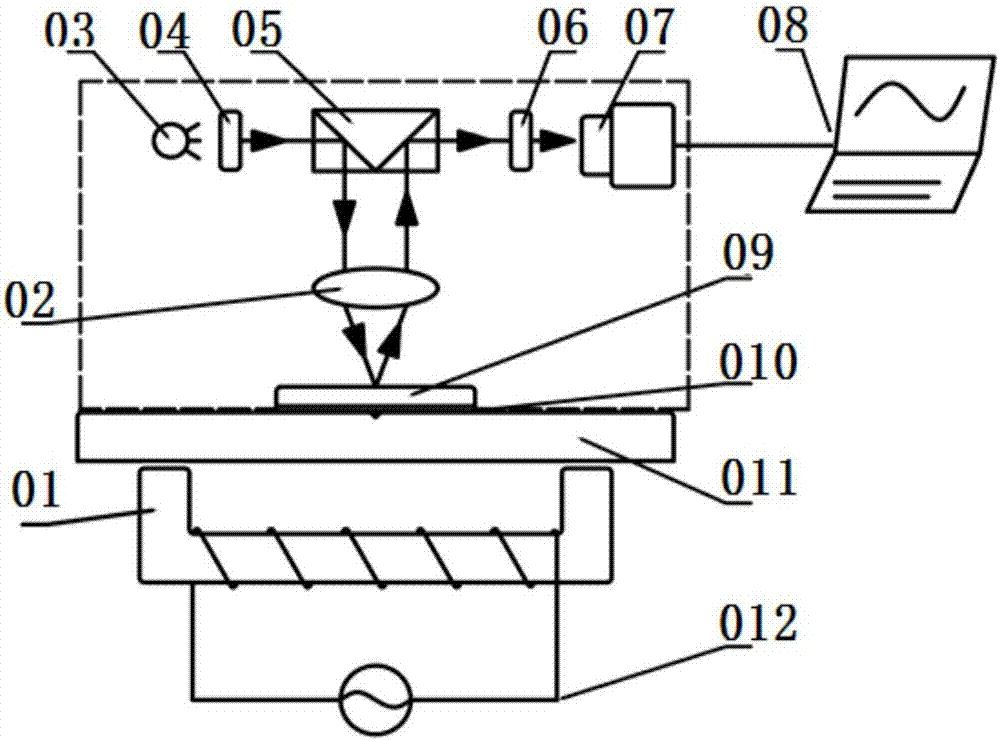

[0021] like figure 1 As shown, it is a specific structural diagram of the non-destructive testing system for weld texture structure of the present invention, which includes structures such as an alternating magnetic field generator 5, a magneto-optical sensor 4 and a processor, wherein the magnetic field generator 5 is used for testing the weld The workpiece 3 is alternately excited, so that the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com