Client-based oxygen production equipment remote fault diagnosis system and fault diagnosis method

A fault diagnosis system and technology for oxygen production equipment, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of economic loss, affecting users' use, long shutdown and maintenance time, etc., to reduce economic losses and improve. The effect of maintenance efficiency and shortening maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A client-based remote fault diagnosis system and fault diagnosis method for oxygen-generating equipment of the present invention will be described in detail below in conjunction with the embodiments and drawings.

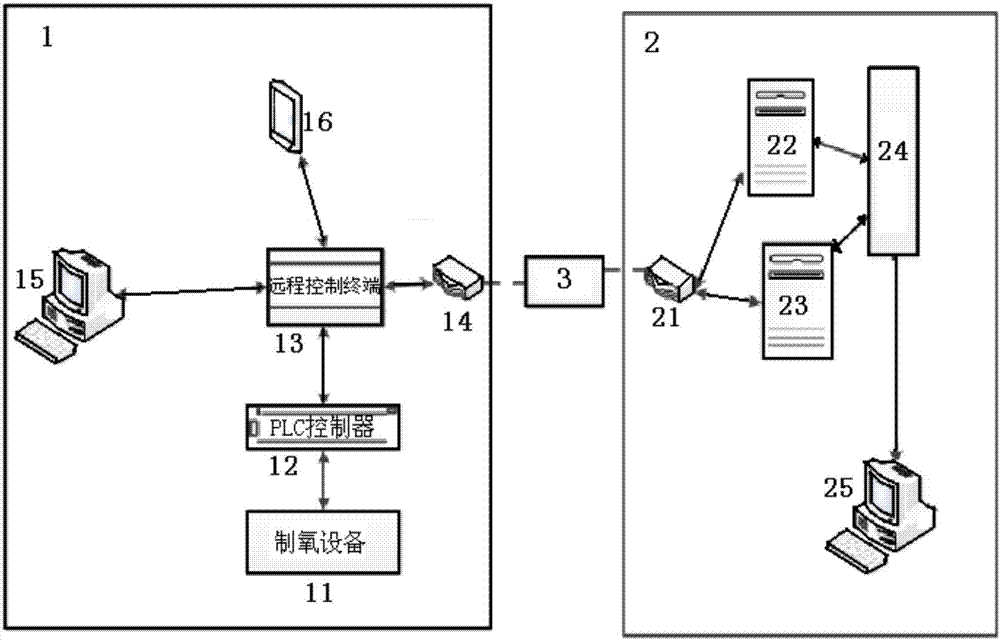

[0031] Such as figure 1 As shown, the client-based remote fault diagnosis system for oxygen production equipment of the present invention includes an on-site oxygen production station 1 and a remote technical service center 2 that communicates with the on-site oxygen production station 1 through a network 3. The on-site oxygen production The station 1 is an on-site oxygen production station 1 distributed in different regions and different locations, and the remote technical service center 2 includes: a service center router 21 connected in sequence to the on-site oxygen production station 1 through the network 3, The data server 22 for receiving the data of the on-site oxygen generation station 1 is analyzed and stored, and the result is fed back to the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com