Concentric high-speed stranding machine

A stranding machine, concentric technology, applied in the field of stranding machines, can solve the problems of large machine delivery, high power consumption, low production efficiency, etc., and achieve the effects of small space occupation, small air resistance, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

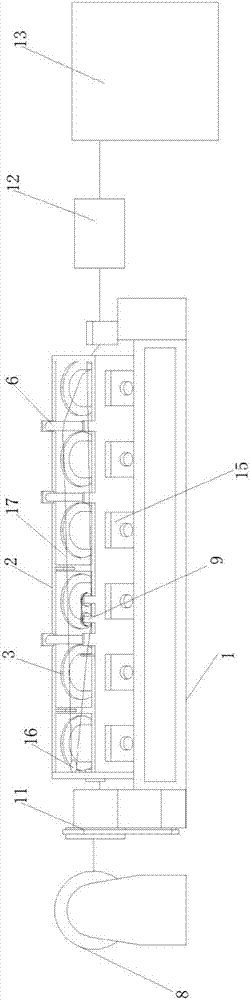

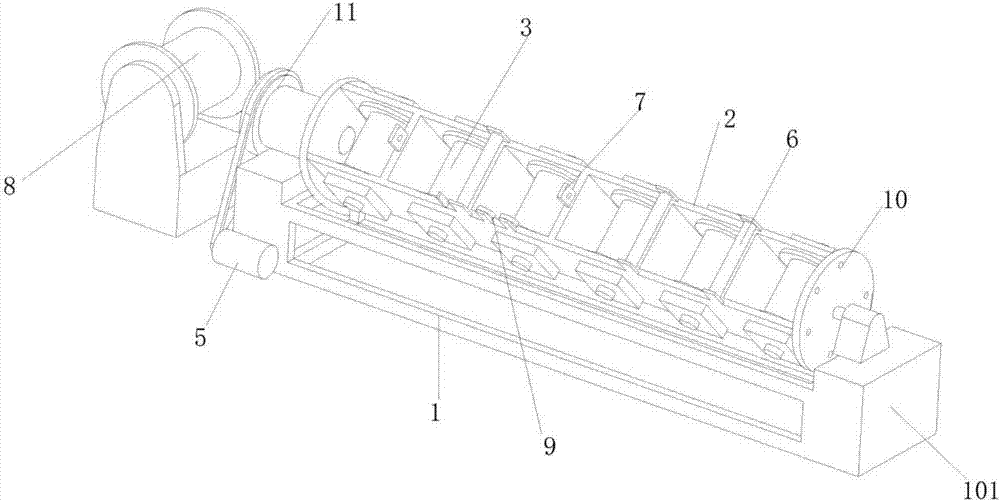

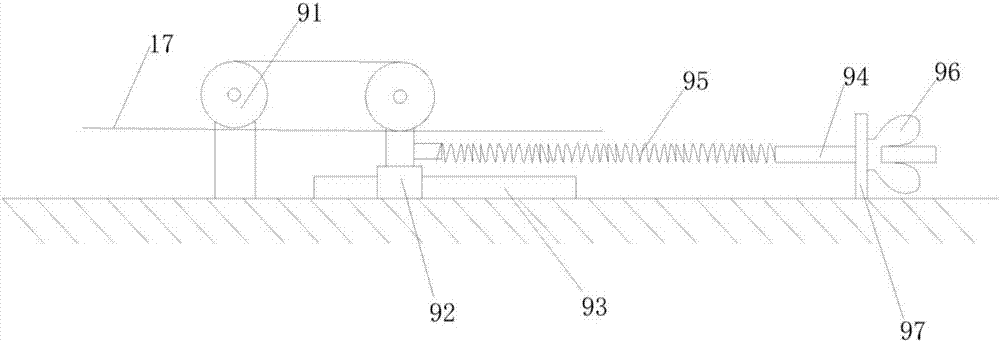

[0024] like figure 1 , 2 As shown in and 3, a concentric high-speed stranding machine includes a frame 1 and a twisting system placed on the frame 1, and also includes a pulling machine 12 and a winding system for pulling and winding the twisted cables in sequence. The wire machine 13, the twisting system rotates along its axis, that is, it rotates relative to the frame 1 to realize the twisting of the multi-strand cables, and then the twisted cables are drawn and then wound up by the wire take-up machine 13 , to realize the process of continuous twisting and cable, in this twisting machine, the twisting system includes a bracket 2 that is rotatably connected to the frame 1 through the bearing seats at both ends, and the bracket 2 is evenly distributed in the same straight line direction A plurality of pay-off wheels 3 are arranged, and the pay-off wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com