Large object plane X-ray stripe image converter tube and electronic optical imaging system

An X-ray and image-changing tube technology, which is applied in the direction of X-ray tube electrodes, X-ray tubes, X-ray tube components, etc., can solve the problems of large electrode spacing, poor anti-interference, and affecting system imaging performance, etc. Spacing, the effect of improving the anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

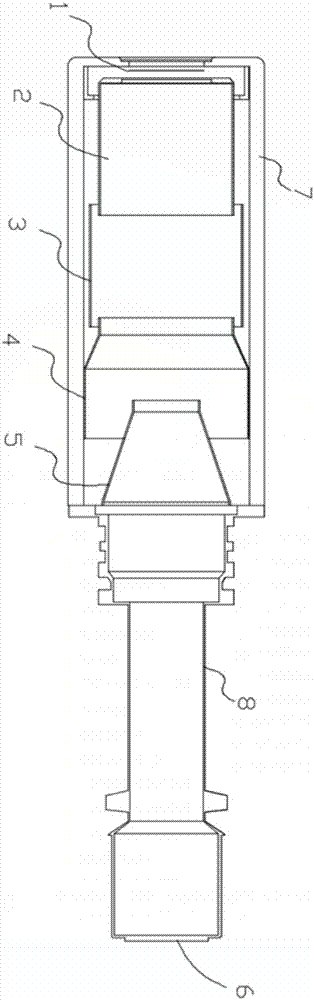

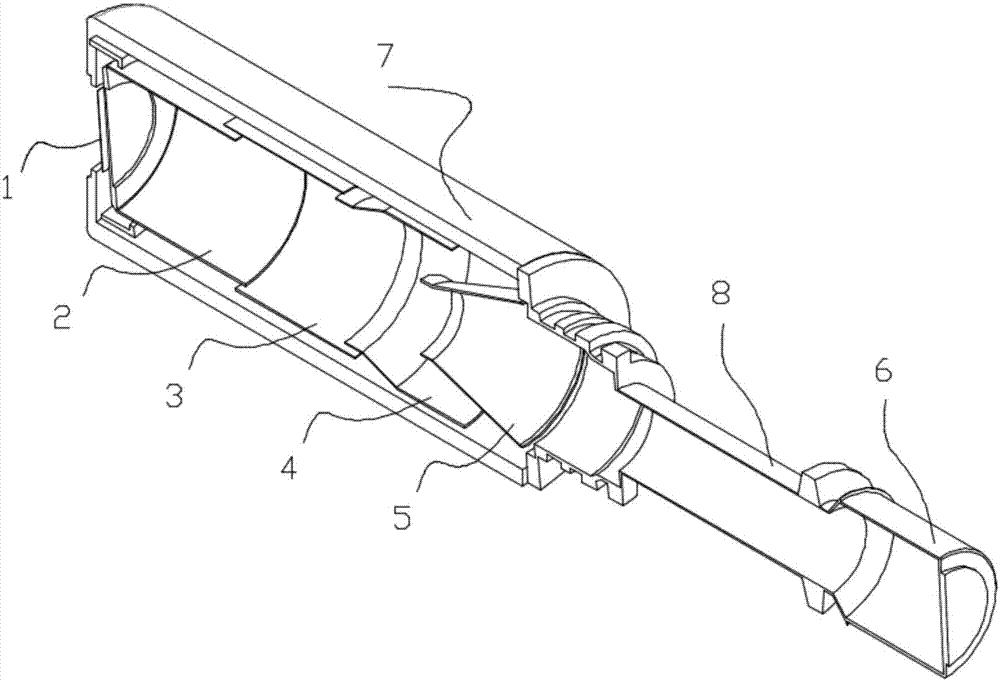

[0039] see figure 1 and figure 2 , this embodiment provides a large object plane X-ray stripe image transformation tube, including an insulating jacket 7 and a metal sleeve 8 connected to each other. The insulating jacket 7 is made of insulating material. As a preferred insulating material, the insulating jacket 7 is made of ceramics.

[0040] When the X-ray stripe image transformation tube with large object surface is working, it will generate a lot of heat. By making the material of the insulating jacket 7 be ceramic, it can not only insulate, but also play a good role in high temperature resistance. In this embodiment, the inside of the insulating jacket 7 and the metal sleeve 8 is a vacuum environment, and its vacuum degree must be lower than 0.005Pa. By drawing a vacuum, the electron beam can be kept in a vacuum, preventing ionization of the air.

[0041] A cathode 1, a grid 2, a focusing electrode assembly, and an anode 5 are arranged in sequence in the insulating ja...

Embodiment 2

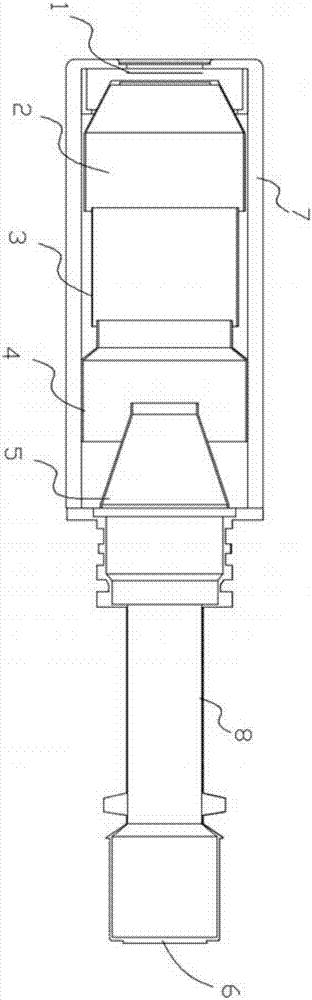

[0057] Such as image 3 , Figure 4 As shown, the present embodiment provides another large object plane X-ray stripe image transformation tube. The structure of the large object plane X-ray stripe image transformation tube in this embodiment is basically the same as that of the large object plane X-ray stripe image transformation tube in Embodiment 1. The same, the difference between the two is that this embodiment provides another grid 2, and the dimensional relationship between the grid 2 and the first focusing electrode 3, specifically as follows:

[0058] The head end of the grid 2 is a cone, the tail end of the grid 2 is a cylinder, and the first focusing electrode 3 is a cylinder. The inner diameter of the tail end of the grid 2 is larger than the outer diameter of the first focusing electrode 3, and the first focusing electrode The inner diameter of 3 is larger than the outer diameter of the first cylindrical section, the outer diameter of the first focusing pole 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com