Oblique position plumb electric welding method

A welding method and tilting position technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low welding efficiency and achieve the effects of improved welding efficiency, faster flow speed, and guaranteed welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

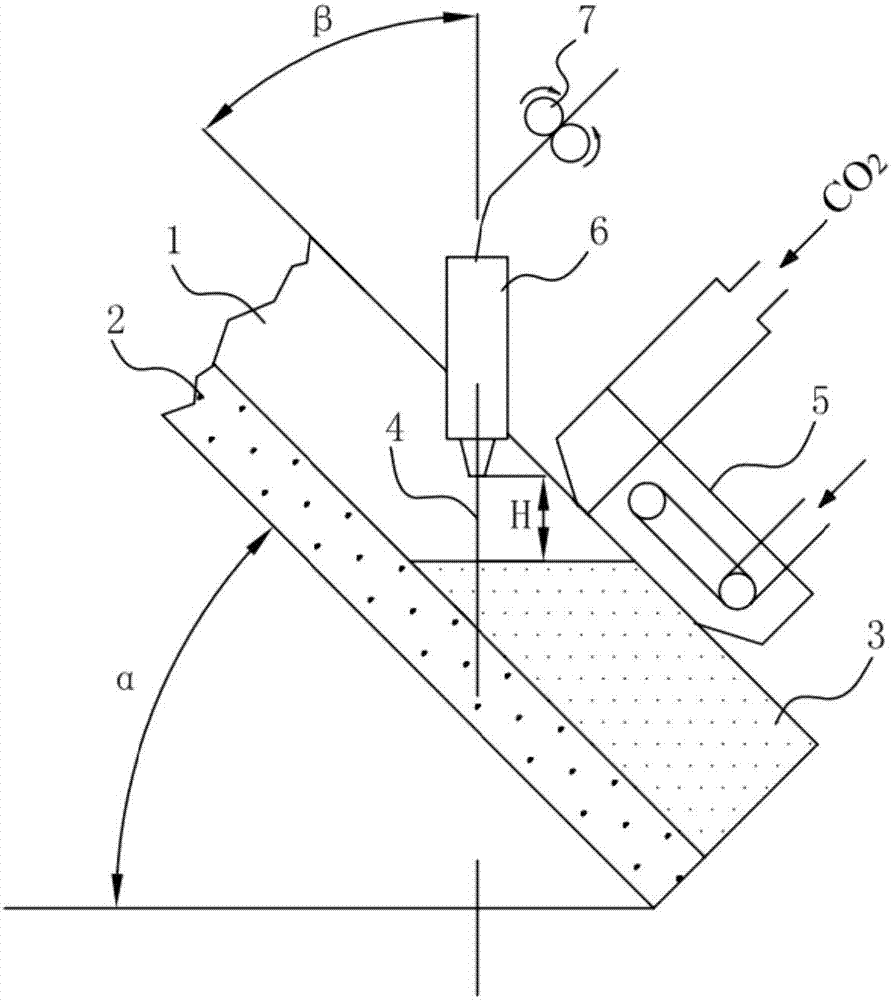

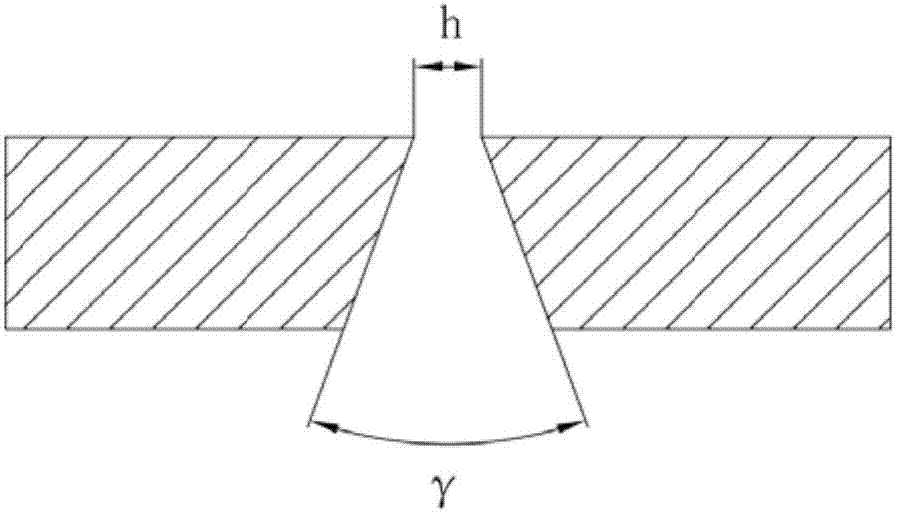

[0026] Such as Figure 1-4 As shown, the present embodiment provides a vertical gas-electric welding welding method in an inclined position, comprising the following steps:

[0027] (1) Partially treat the surface on both sides of the groove of the steel plate to be welded 1 inclined to the horizontal plane, and remove rust, moisture and oil;

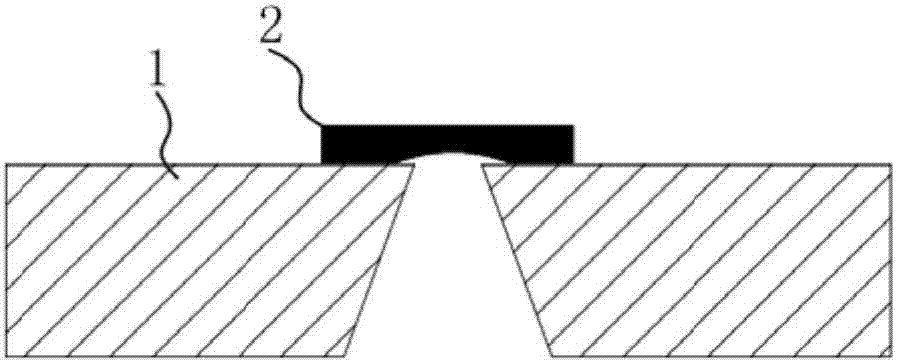

[0028] (2), a liner 2 is pasted on the back of the steel plate 1 to be welded;

[0029] (3), using CO 2 As a shielding gas, the welding torch releases the welding wire 4 inside the groove of the steel plate 1 to be welded for welding, so that the liquid metal molten pool fills the entire groove, and uses the gasket 2 on the back of the groove and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com