Double sludge oxidation ditch denitrification phosphate-removing apparatus and method thereof

A technology of denitrification phosphorus removal and oxidation ditch, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Nitrifying bacteria carbon source competition and other issues, to achieve the effect of guarantee, increase biomass, and improve nitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

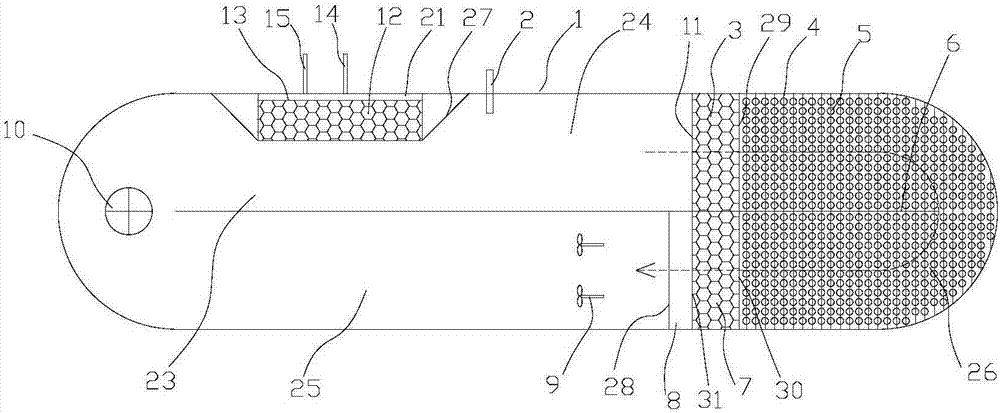

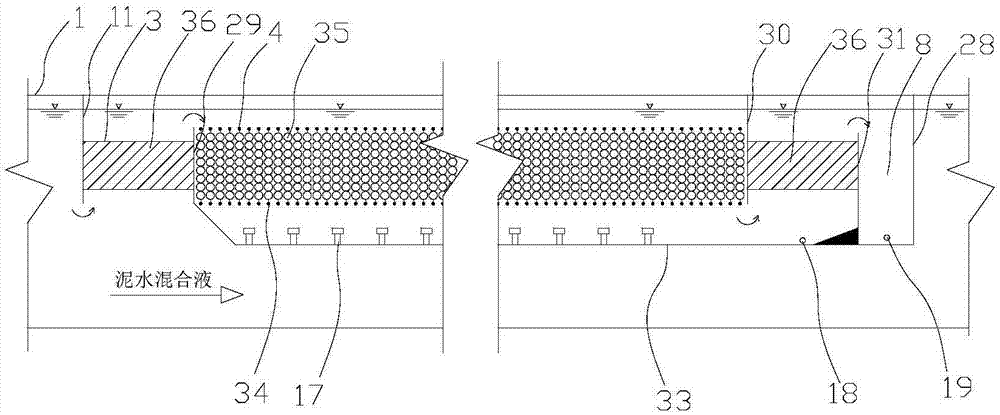

[0037] Such as Figure 1 to Figure 4 As shown, a dual sludge oxidation ditch denitrification and dephosphorization device includes an oxidation ditch 1 in which there are successively connected outlet areas, a pre-anaerobic area 23, an anaerobic area 24, and independent nitrification along the flow of sewage. Zone 26, anoxic zone 25 and water outlet zone. The independent nitrification zone 26 is separated from the anaerobic zone 24 and the anoxic zone 25 by the first baffle 11 and the second baffle 28, respectively. The mud-water separation zone 3, the filling zone 5, the second mud-water separation zone 7 and the steady flow zone 8, so that the main channel of the oxidation ditch 1 (except the accidental area of the independent nitrification zone 26) and the sludge in the independent nitrification zone 26 mutually Independent, forming a dual sludge system that does not interfere with each other. The packing area 5 is used to adsorb nitrifying bacteria, and a plurality of aer...

Embodiment 2

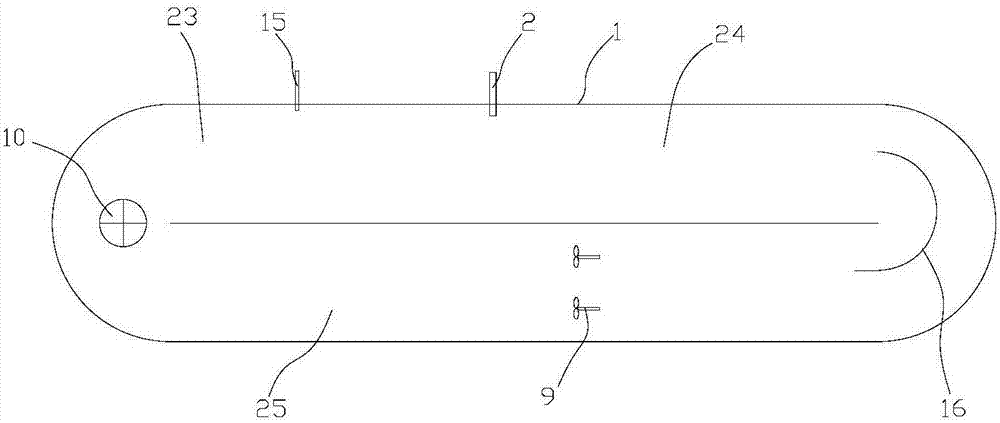

[0046] The Carrousel oxidation ditch with the secondary settling tank 22 and the sludge return line can also be upgraded, that is, such as Figure 5 As shown, the water outlet device in the pre-anaerobic zone 23 is cancelled. After the micro-aerator 10, the mud-water mixture is sent to the secondary settling tank 21 through the original outlet ditch 21, and the sludge separated by the mud-water separator re-enters Anaerobic zone 23. Transform the upper part of a corridor of the Carrousel oxidation ditch into Figure 5 In the independent denitrification zone 26 shown in the figure, except for an inverted umbrella type aerator at the back end of the hypoxic zone for micro-aeration, the other micro-aerators are stopped. The rest of the operation steps are the same as in the first embodiment, and a better processing effect can also be achieved.

[0047] An outlet ditch is provided in the oxidation ditch of the pre-anaerobic zone to communicate with a secondary settling tank, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com