Polymer containing aza-crown ether structure as well as preparation method and application thereof

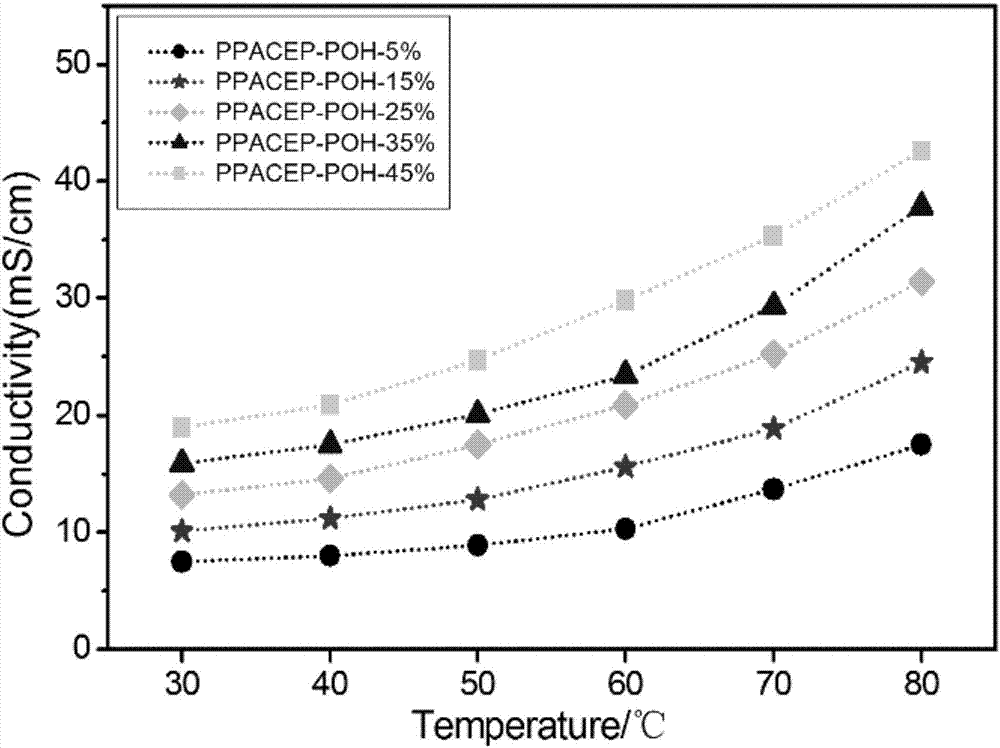

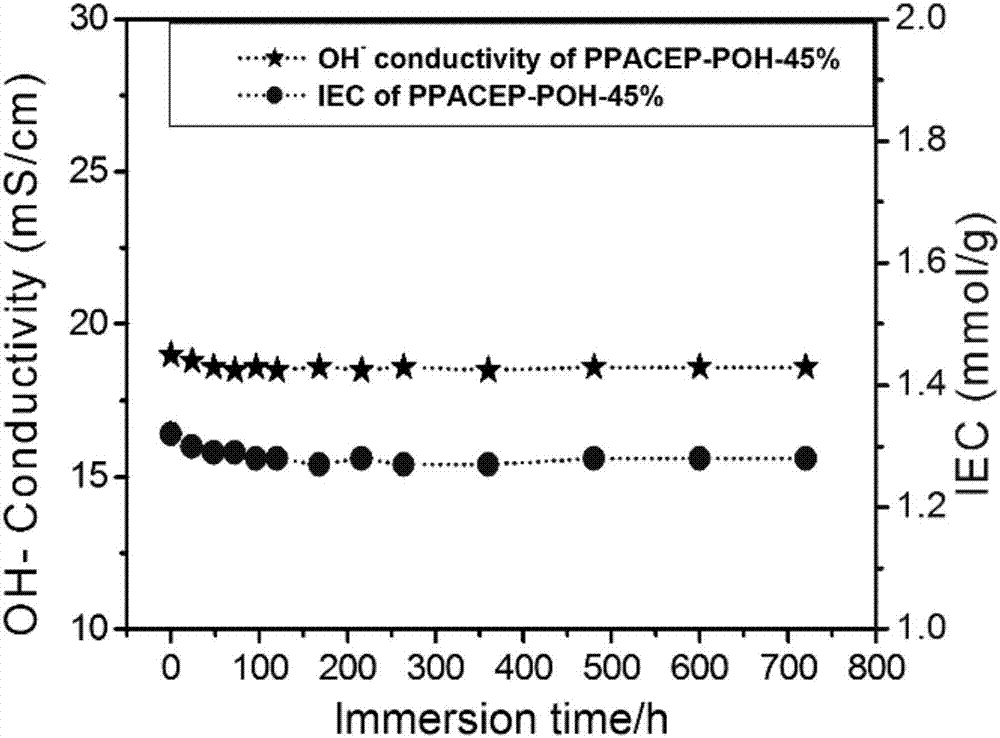

A technology of azacrown ethers and polymers, which is applied in the field of anion exchange membranes containing azacrown ether structures and its preparation, can solve problems that do not involve the research of polyphosphazene anion exchange membranes loaded with azacrown ethers, and achieve Excellent alkali stability, excellent alkali resistance, and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

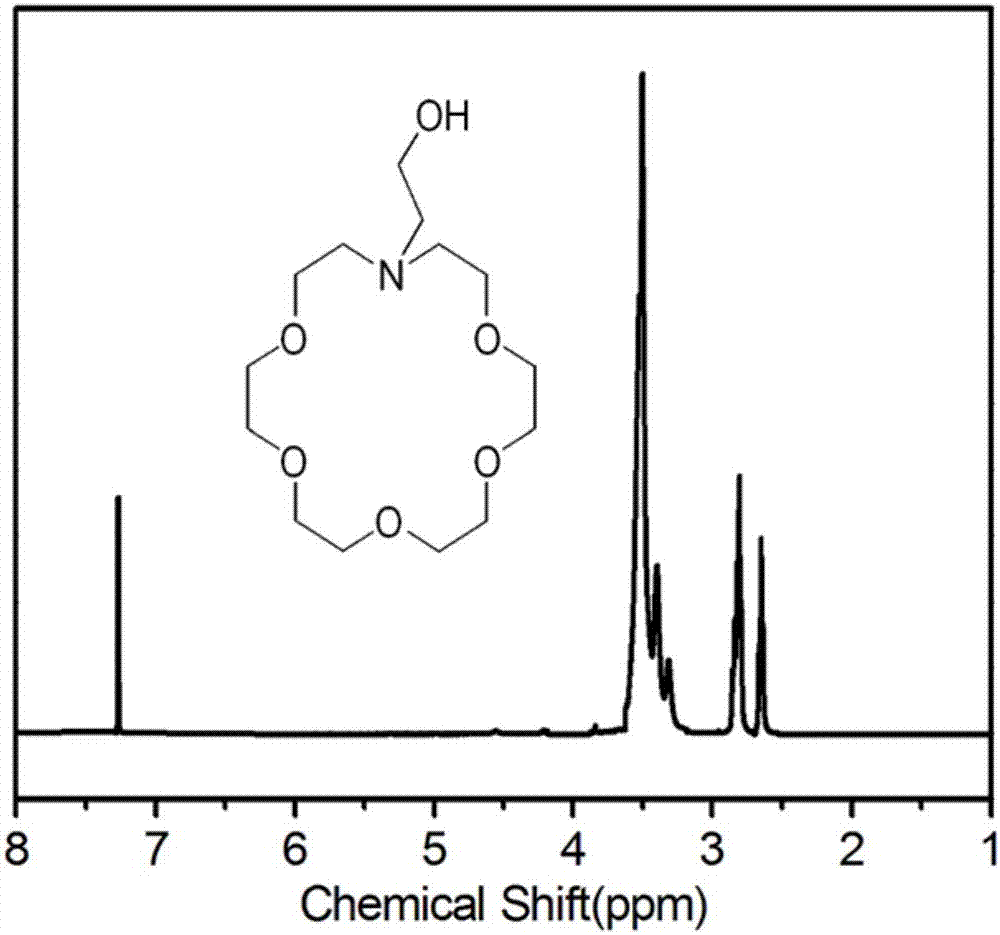

[0040] Take 6.14g of the hydroxy crown ether structure (z=1, m=3) represented by formula (2) and 1.2eq of sodium metal into 1,4-dioxane, heat to 60°C, and react for 24h. Then cool to room temperature, and suction filter to obtain a 1,4-dioxane solution of crown ether sodium salt;

[0041] Add the 1,4-dioxane solution of the above-mentioned crown ether sodium salt into a THF solution containing 23.2g of polydichlorophosphazene, and react at 60°C for 48h;

[0042] Add 33.44g of unsubstituted n-amyl alcohol and 1.2eq of sodium metal into THF, react at room temperature for 4h, and then filter with suction to obtain a THF solution of n-amyl alcohol sodium salt;

[0043] Add the obtained THF solution of fatty alcohol sodium salt into the above solution, continue to react for 24 h, then cool to room temperature, concentrate the obtained reaction solution to obtain a viscous liquid, wash with deionized water, and obtain a light yellow elastomer;

[0044] Dissolve the resulting elasto...

Embodiment 2

[0047]Take 18.42g of the hydroxy crown ether structure (z=1, m=3) represented by formula (2) and 1.2eq of sodium metal into 1,4-dioxane, heat to 60°C, and react for 24h. Then cool to room temperature, and suction filter to obtain a 1,4-dioxane solution of crown ether sodium salt;

[0048] Add the 1,4-dioxane solution of the above-mentioned crown ether sodium salt into a THF solution containing 23.2g of polydichlorophosphazene, and react at 60°C for 48h;

[0049] Add 29.92g of unsubstituted n-amyl alcohol and 1.2eq of metal sodium into THF, react at room temperature for 4h, and then filter with suction to obtain a THF solution of n-amyl alcohol sodium salt;

[0050] Add the obtained THF solution of fatty alcohol sodium salt into the above solution, continue to react for 24 hours, then cool to room temperature, concentrate the obtained reaction solution to obtain a viscous liquid, wash with deionized water, and obtain a light yellow elastomer;

[0051] Dissolve the resulting el...

Embodiment 3

[0054] Take 30.7g of the hydroxy crown ether structure (z=1, m=3) represented by formula (2) and 1.2eq of sodium metal, add it to 1,4-dioxane, heat to 60°C, and react for 24h. Then cool to room temperature, and suction filter to obtain a 1,4-dioxane solution of crown ether sodium salt;

[0055] Add the 1,4-dioxane solution of the above-mentioned crown ether sodium salt into a THF solution containing 23.2g of polydichlorophosphazene, and react at 60°C for 48h;

[0056] Add 26.4g of unsubstituted n-amyl alcohol and 1.2eq of sodium metal into THF, react at room temperature for 4h, and then filter with suction to obtain a THF solution of n-amyl alcohol sodium salt;

[0057] Add the obtained THF solution of fatty alcohol sodium salt into the above solution, continue to react for 24 hours, then cool to room temperature, concentrate the obtained reaction solution to obtain a viscous liquid, wash with deionized water, and obtain a light yellow elastomer;

[0058] Dissolve the resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com