Wine distillation device

A kind of wine steaming equipment and technology of wine fermented grains, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of affecting the quality of wine and mixing in, and achieve the effects of reducing high-boiling impurities, lowering the temperature of wine, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

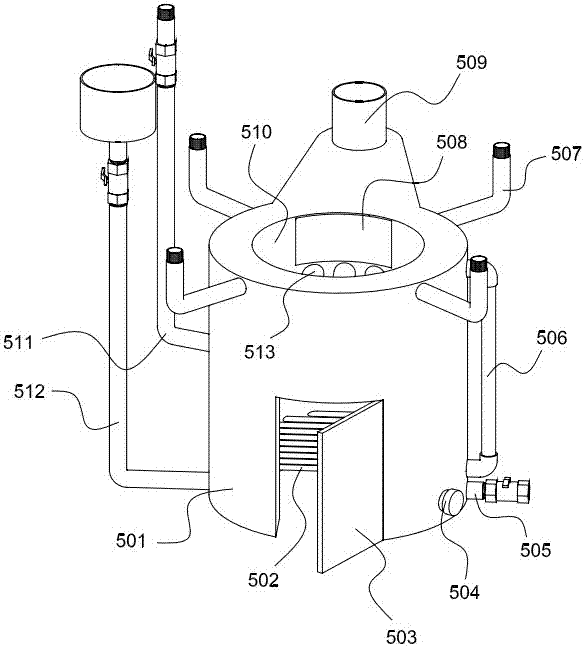

[0027] like Figure 1-5 As shown, the present embodiment includes a steam generator 501 for generating the water vapor required for heating the wine grains, a still for containing the wine grains, a wine vapor pipe 200 for guiding the wine vapor into the condenser 100 from the still, The condenser 100 for condensing the wine vapor introduced by the pipe 200 and the blower, the first air guide pipe and the second air guide pipe for finally blowing air into the wine grains.

[0028] like figure 1 As shown, the steam generator 501 is a steam boiler, the furnace body of the steam boiler is an annular water tank, the inner side of the inner wall 510 of the annular water tank is a furnace, the furnace bridge 502 is arranged below the furnace, and a plurality of tubes and the inner wall of the annular water tank are arranged above the furnace. The heat exchange tube 513 welded at 510, the tube inner space of the heat exchange tube 513 communicates with the inner space of the annular...

Embodiment 2

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , the present embodiment includes a steam generator 501 for generating the water vapor required for heating the wine grains, a still for containing the wine grains, a wine steam pipe 200 for leading the wine steam from the still to the condenser 100, and a wine steam pipe 200 A condenser 100 for condensing the imported wine vapor and a blower and an air duct for finally blowing air into the wine grains.

[0035] Refer to the specific structure of steam generator 501, distiller, blower and air duct figure 1 , figure 2 , image 3 , Figure 4 Shown and written description of Example 1.

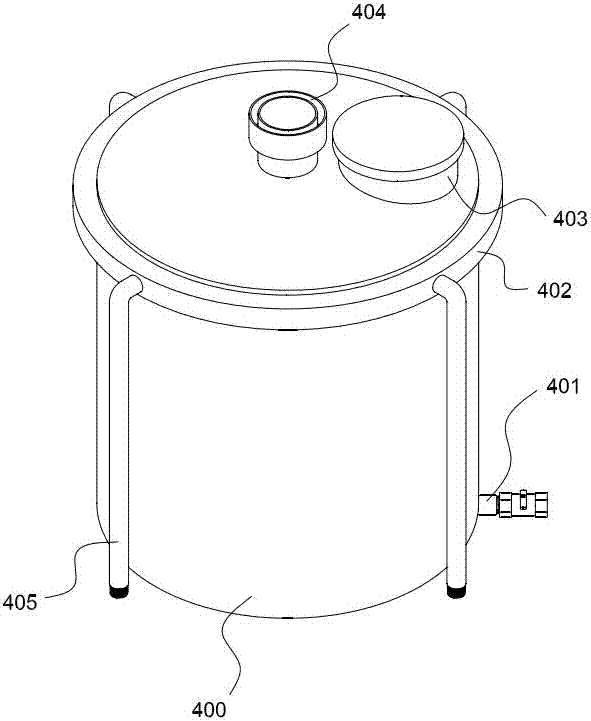

[0036] like Image 6 As shown, one end of the wine vapor tube 200 is connected to image 3 The wine vapor outlet 404 of the shown distillation tank 400 is connected in a water seal, and the other end is connected in a water seal with the water tank 101 of the condenser 100 . A water jacket layer 202 is sheathed on ...

Embodiment 3

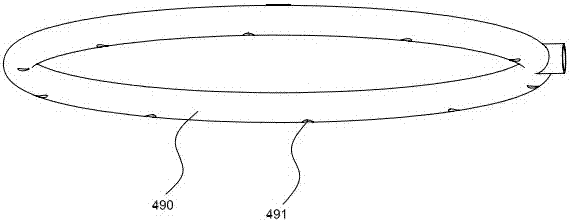

[0039] refer to figure 1 As shown, the side of the steam generator 501 in this embodiment does not have an "L"-shaped air duct 511 and an air distribution pipe 490 connected to the "L"-shaped air duct 511 .

[0040] refer to figure 1 , Figure 7 As shown, the space inside the retort 400 of this embodiment containing the fermented grains is the distilling space for the fermented grains. An annular vapor pressure equalization chamber 402 is arranged above the outside of the retort 400, and the vapor pressure equalization chamber 402 is connected with four upper half sections of the first steam guide pipe 405 located outside the retort 400 and four first steam pipes located outside the retort 400. Two steam guide pipes 406 , the inner space of the steam pressure equalization chamber 402 communicates with the pipe inner space of the first half section 405 of the first steam guide pipe 406 and the pipe inner space of the second steam guide pipe 406 . The lower end of the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com