Nodulizing and inoculating treatment process for nodular cast iron

A technology of nodular cast iron and spheroidization inoculation, applied in the field of metallurgy, can solve problems such as shrinkage porosity, and achieve the effects of eliminating shrinkage holes, improving efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

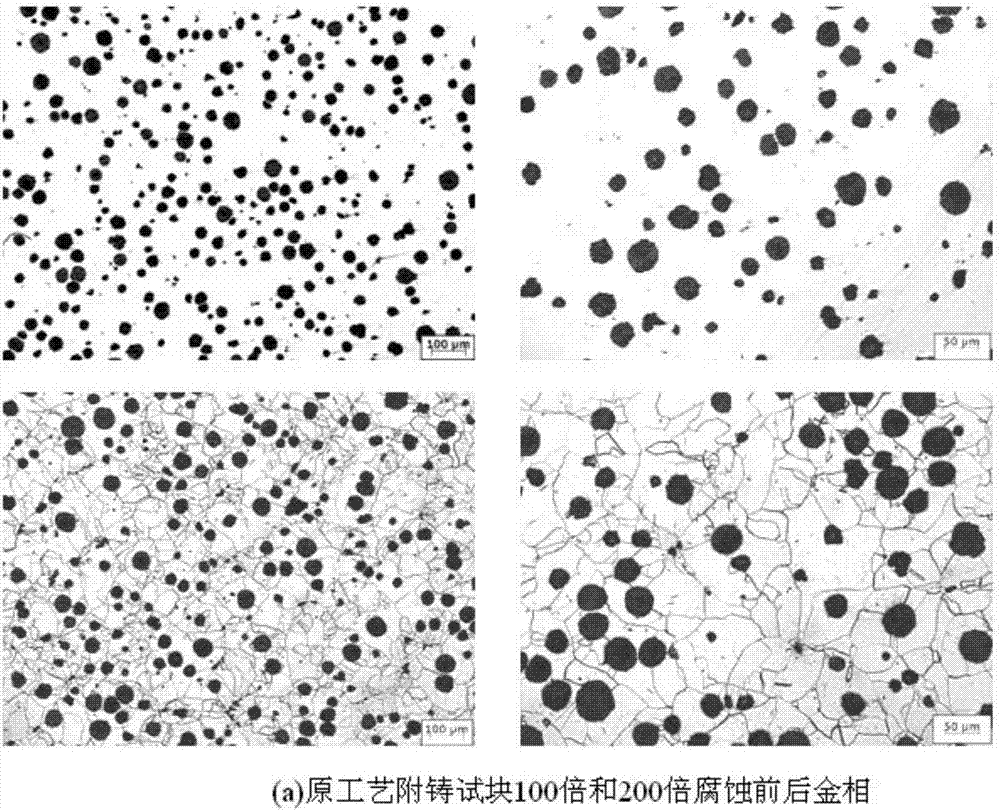

[0020] Scheme 1: The existing pouring wind power 750kw wheel hub, the middle parting, adopts the ceramic tube bottom injection process, and places three heat preservation risers on the top. During the experiment, there are occasional defects larger than φ3-φ5 at the parting surface. meet the requirements.

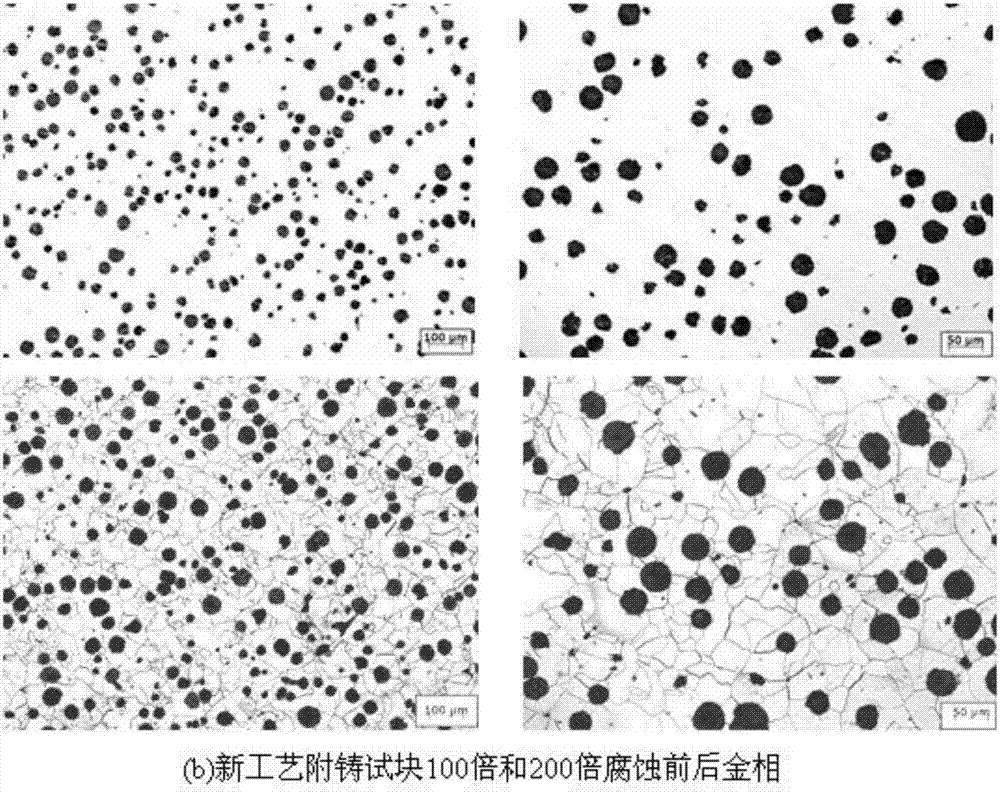

[0021] Solution 2: In view of the above problems, the smelting process is now changed, as follows:

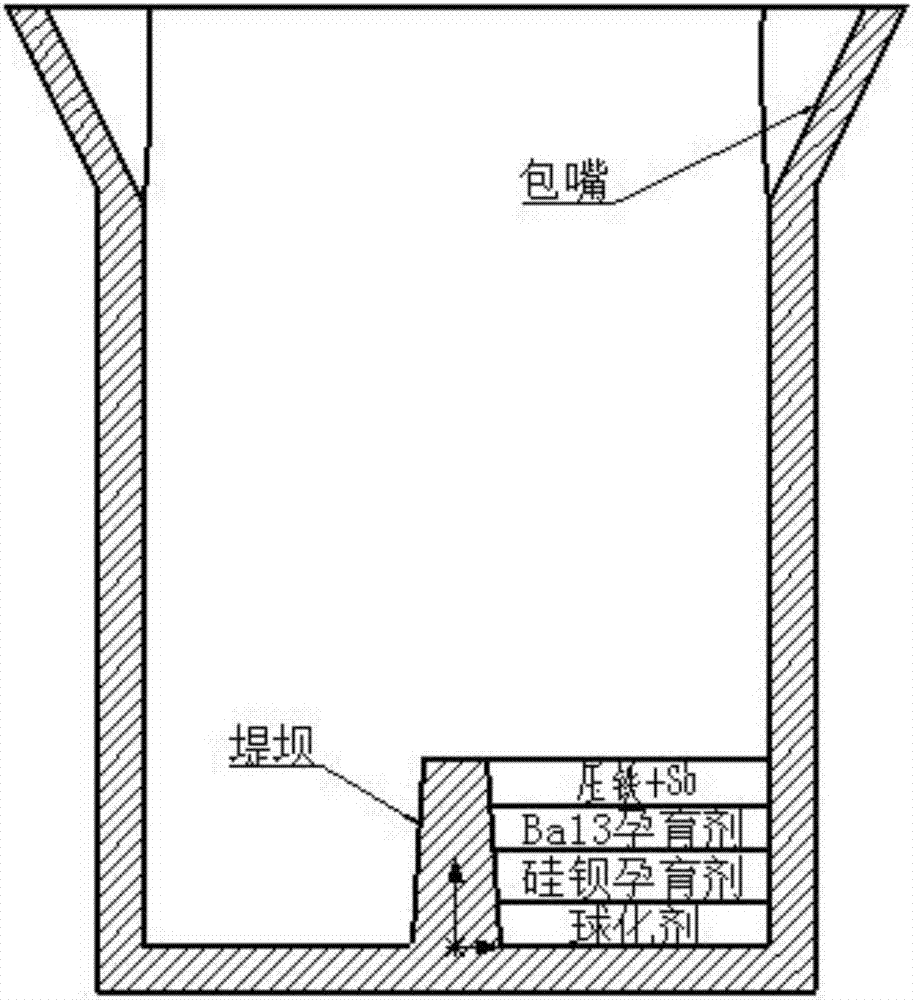

[0022] A spheroidizing inoculation process for ductile iron, comprising the steps of:

[0023] Step 1. Add in sequence in a pit of the spheroidizing bag: 1% spheroidizing agent B, 0.2% barium silicon inoculant, 0.3% Ba13 long-acting inoculant and pressed iron;

[0024] Step 2: Pour molten iron from the furnace into another pit, add 0.15%-0.3% silicon barium inoculant when tapping the iron, and add 0.1%-0.2% special effect 1# flow inoculant when pouring, in order to ensure spheroidization, the ball The finished molten iron S≤0.012%, Mg=0.040%±0.004.

[0025] The nodularize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com