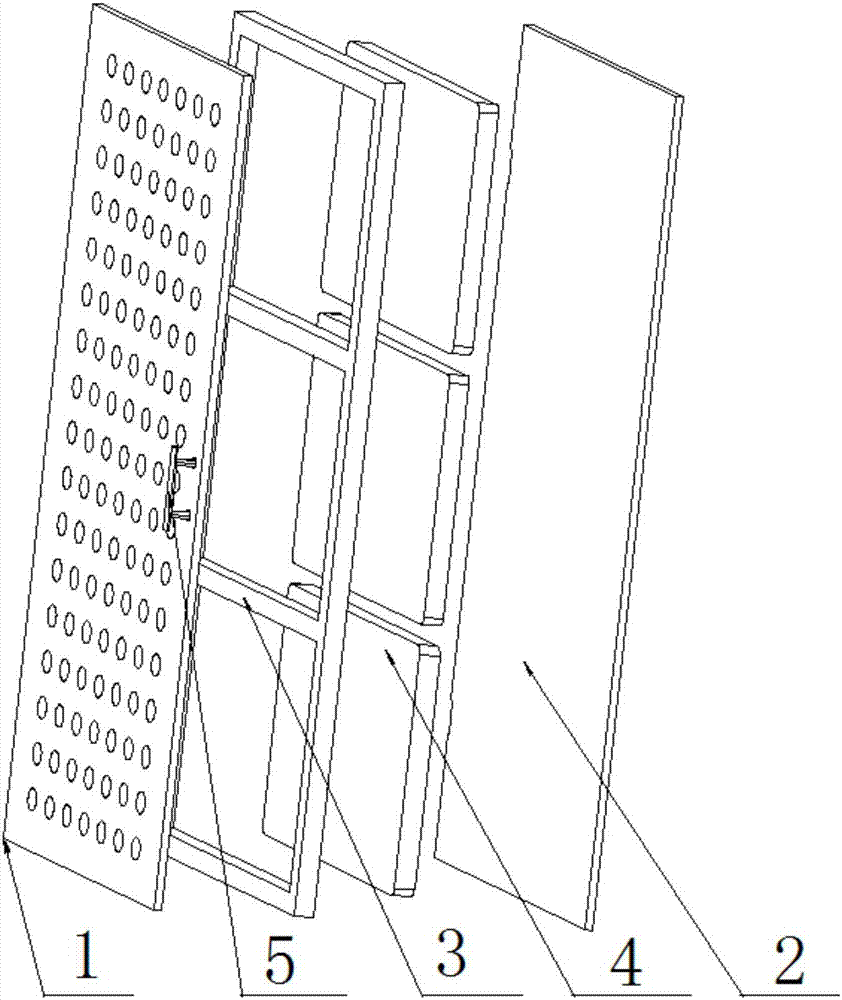

Sound absorption door

A sound-absorbing panel and door-back technology, which is applied in the field of sound-absorbing doors, can solve problems such as poor sound insulation and impact, and achieve a remarkable sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] γ-Al2O3: nickel nitrate: aluminum isopropoxide mass ratio = 4:1:2, 8g γ-Al2O3, 2g nickel nitrate, 4g aluminum isopropoxide;

[0018] Step 1. First, γ-Al2O3, nickel nitrate, 15ml 2mol / L sodium hydroxide, and 15ml absolute ethanol are ultrasonically oscillated in an oil bath at 90°C for 2 hours to remove impurities;

[0019] Step 2. Put 10ml of silica sol, aluminum isopropoxide, 200ml of deionized water, and 7ml of liquid templating agent triethylamine in an ultrasonic oscillating water bath at 90°C for 2 hours to remove impurities;

[0020] Step 3. Add the silica sol dropwise into the flask, then dropwise add deionized water, absolute ethanol, and sodium hydroxide dropwise at a rate of 20 drops per minute, and simultaneously heat the oil bath with magnetic stirring for 3 hours;

[0021] Step 4. Add aluminum isopropoxide to the above solution, then add the templating agent triethylamine dropwise at a rate of 30 drops per minute, and heat at 80°C in an oil bath with magnet...

Embodiment 2

[0030] The preparation method is the same as in Example 1; the difference is that the mass ratio of γ-Al2O3: nickel nitrate: aluminum isopropoxide is 4:3:2, 8g γ-Al2O3, 6g nickel nitrate, and 4g aluminum isopropoxide.

Embodiment 3

[0032] The preparation method is the same as in Example 1; the difference is that the mass ratio of γ-Al2O3: nickel nitrate: aluminum isopropoxide is 4:1:3, 8g γ-Al2O3, 2g nickel nitrate, and 6g aluminum isopropoxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com