Portable photovoltaic assembly used for charging and manufacturing method of photovoltaic assembly

A technology of photovoltaic modules and manufacturing methods, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of being unable to meet the requirements of portability, light weight, wear resistance, poor portability, and wear resistance, and achieve improved Practicality and universality, improving reliability and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

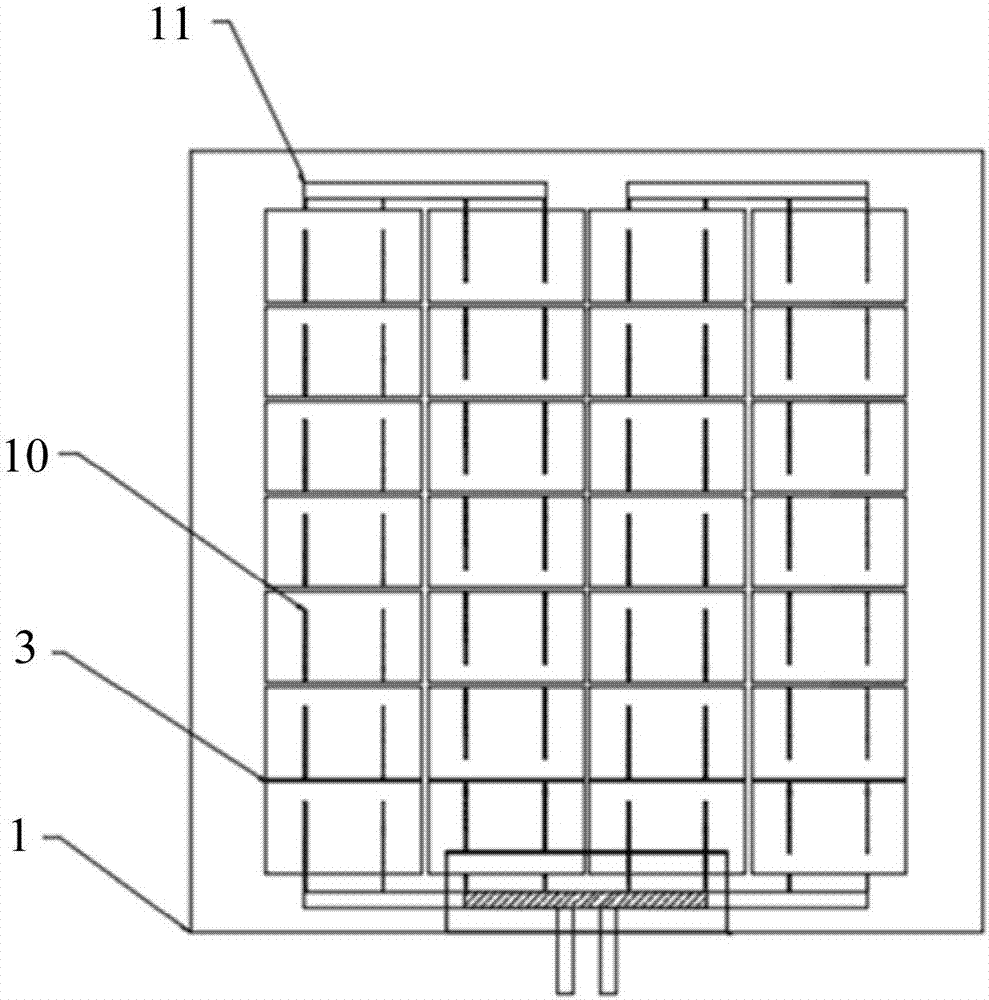

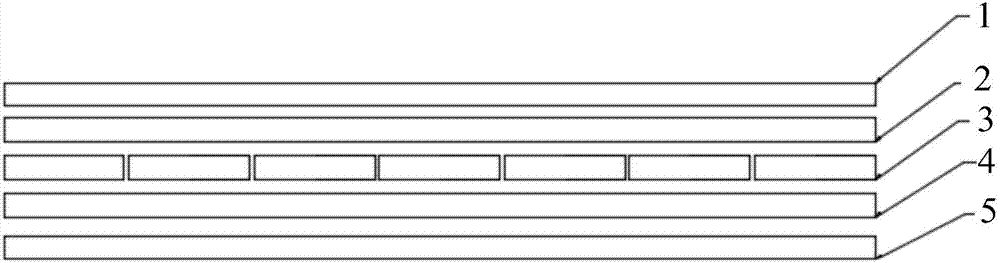

[0032] The manufacturing method of the portable photovoltaic module for charging in this embodiment includes: obtaining battery slices; welding the battery slices to obtain a battery slice array; 1. The second glass is subjected to high-temperature vacuum lamination to obtain a component; the component is cooled, and anti-collision corners are fixed on the periphery of the component; the positive and negative electrodes of the component are connected to the voltage regulation module.

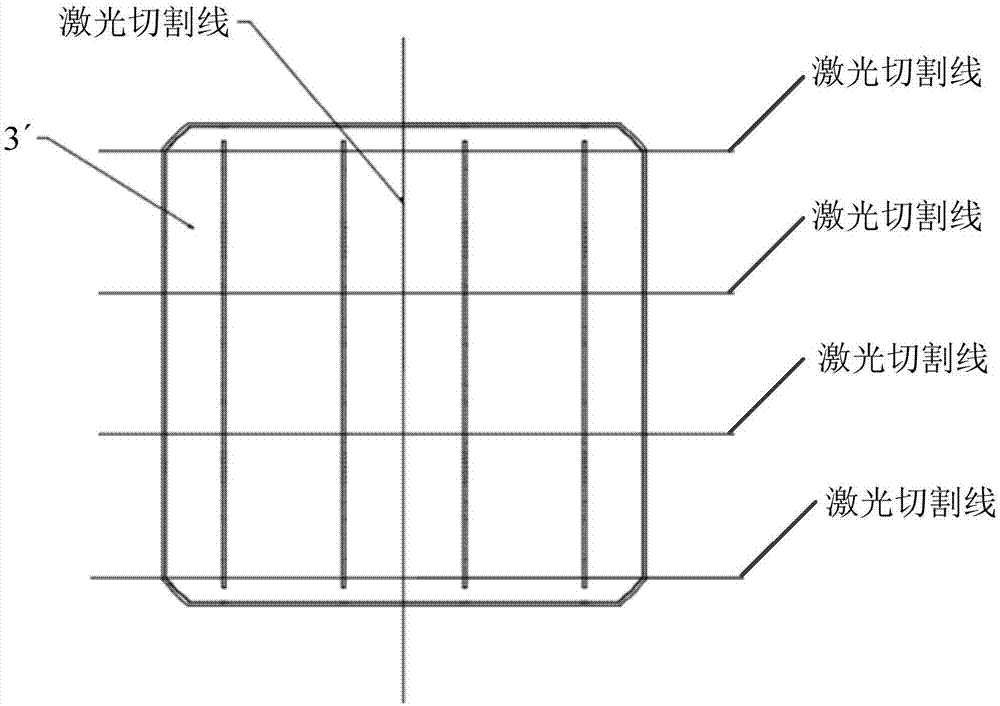

[0033] In this embodiment, the battery sheet is obtained by cutting the M2 specification P-type single-crystal double-sided battery into equal parts, that is, it is obtained by laser scribing into N equal parts. The value of N can be determined according to actual needs. In this embodiment N can be 6 in the example. Specifically, selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com