Method for preparing heavy metal removed pea protein from pea starch wastewater

A technology of pea protein and pea starch, which is applied in the field of pea protein with high protein content, and can solve the problems of complex removal of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

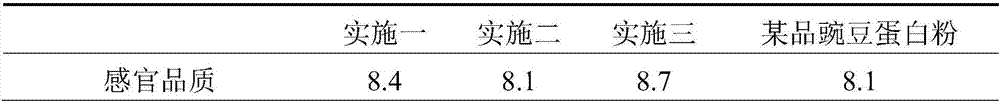

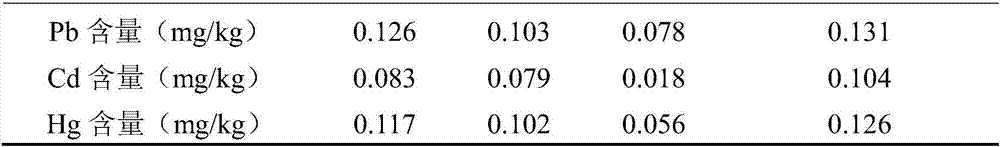

Embodiment 1

[0022] (1) The pea starch wastewater solution is subjected to high-pressure instantaneous sterilization, and is sent into a mechanically stirred and ventilated fermenter, and 5% seeds of Gluconoacetobacter xylinum are inserted, and the temperature is fermented at 25°C for 96h. After the fermentation is over, the pH of the fermented liquid At 4.8, obtain the pea starch wastewater fermented liquid containing microaggregate bacterial cellulose and organic acid;

[0023] (2) The above-mentioned fermented liquid is separated by a centrifuge with a centrifugal force of 3000×g to obtain a supernatant and a precipitate. The supernatant is a fermented organic acid solution chelated with heavy metals, and the precipitate is organic acid chelated and removed once. Heavy metal pea protein, Gluconacetobacter xylinum cells and bacterial cellulose;

[0024] (3) Send the precipitate prepared in step (2) into the slurry tank, add 3 times of water to adjust the slurry, add lye to adjust the pH ...

Embodiment 2

[0031] (1) The pea starch wastewater solution is sterilized by high pressure instantaneously, sent into a mechanically stirred and ventilated fermenter, inserted with 20% gluconoacetobacter xylinum seeds, and fermented at 37° C. for 5 hours. After the fermentation, the pH of the fermented liquid At 4.0 to 4.8, the pea starch wastewater fermentation liquid containing microagglomerated bacterial cellulose and organic acids is obtained;

[0032] (2) The above-mentioned fermented liquid is separated by a centrifuge with a centrifugal force of 2500×g to obtain a supernatant and a precipitate. The supernatant is a fermented organic acid solution chelated with heavy metals, and the precipitate is organic acid chelated and removed once. Heavy metal pea protein, Gluconacetobacter xylinum cells and bacterial cellulose;

[0033] (3) Put the precipitate prepared in step (2) into the slurry tank, add 1 times of water to adjust the slurry, add lye to adjust the pH to 8.5, at 40°C, stir at a...

Embodiment 3

[0040] (1) The pea starch wastewater solution is sterilized by high pressure instantaneously, sent into a mechanically stirred and ventilated fermenter, inserted with 10% gluconoacetobacter xylinum seeds, and fermented at 20° C. for 48 hours. After the fermentation, the pH of the fermented liquid In 4.4, obtain the pea starch wastewater fermented liquid that contains microaggregate bacterial cellulose and organic acid;

[0041](2) The above-mentioned fermented liquid is separated by a centrifuge with a centrifugal force of 2800×g to obtain a supernatant and a precipitate. The supernatant is a fermented organic acid solution chelated with heavy metals, and the precipitate is organic acid chelated and removed once. Heavy metal pea protein, Gluconacetobacter xylinum cells and bacterial cellulose;

[0042] (3) Send the precipitate prepared in step (2) into the slurry tank, add 2 times of water to adjust the slurry, add lye to adjust the pH to 10.0, and dissolve the pea protein at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com