Method for casting high-speed steel-copper tooth-shaped meshing composite roller step by step

A composite roll and high-speed steel technology, which is applied in the field of step-by-step casting of high-speed steel-copper tooth-shaped meshing composite rolls, can solve the problems of composite rolls such as easy cracking, poor thermal conductivity, and low rolling speed, and achieve high strength and toughness at the core , high thermal conductivity, good surface wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

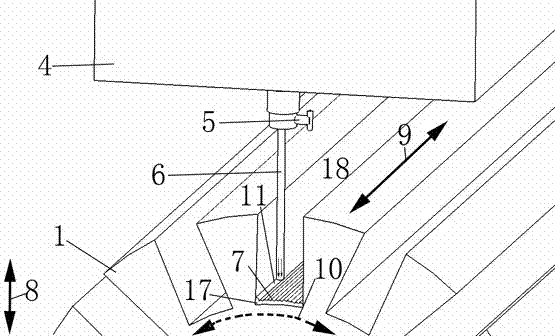

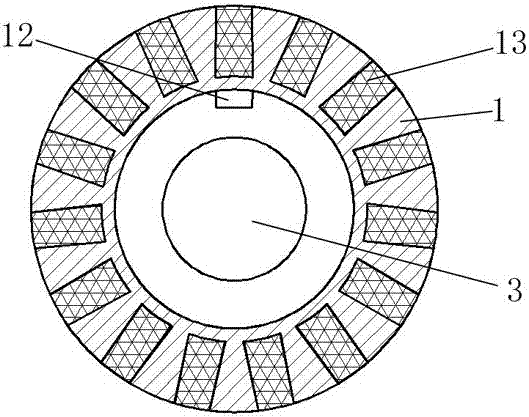

[0052] As shown in the figure, the specific implementation is as follows:

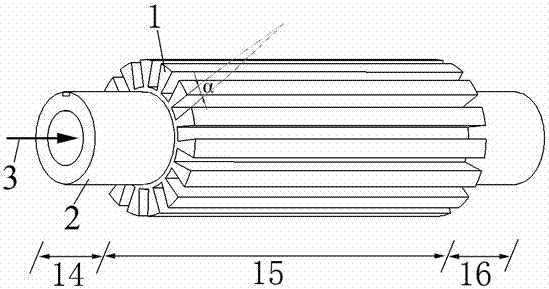

[0053] The total length of the high-speed steel-copper composite roll manufactured in this embodiment is 2580mm; the effective working length of the roll is 1680mm, the outer diameter is 680mm; the two shaft ends are each 450mm long and the diameter is 400mm; the diameter of the cooling water hole is 240mm. The chemical composition of the selected high-vanadium high-speed steel is 1.85C, 1.50Si, 4.90-Cr; 1.35Mo; 0.60Mn; 8.90V by mass percentage, the balance is Fe, and the copper part is pure copper.

[0054] (1) The size of the casting cavity is 2650mm in total length, including 70mm machining allowance; the effective working part of the roll 15 is 1710mm long, including 30mm machining allowance; the outer diameter is 360mm, including machining allowance 20mm; the two shaft ends are 14 and 16 each long 470mm, including machining allowance 40mm; shaft end 14 and 16 diameter 240mm, including machining allowan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com