Workpiece automatic forming machine tool cutting mechanism

A cutting mechanism and automatic forming technology, applied in metal processing mechanical parts, driving devices, manufacturing tools, etc., can solve the problems of reduced work efficiency, unreliable performance, waste of time, etc., and achieve high work efficiency, simple structure, and overall structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

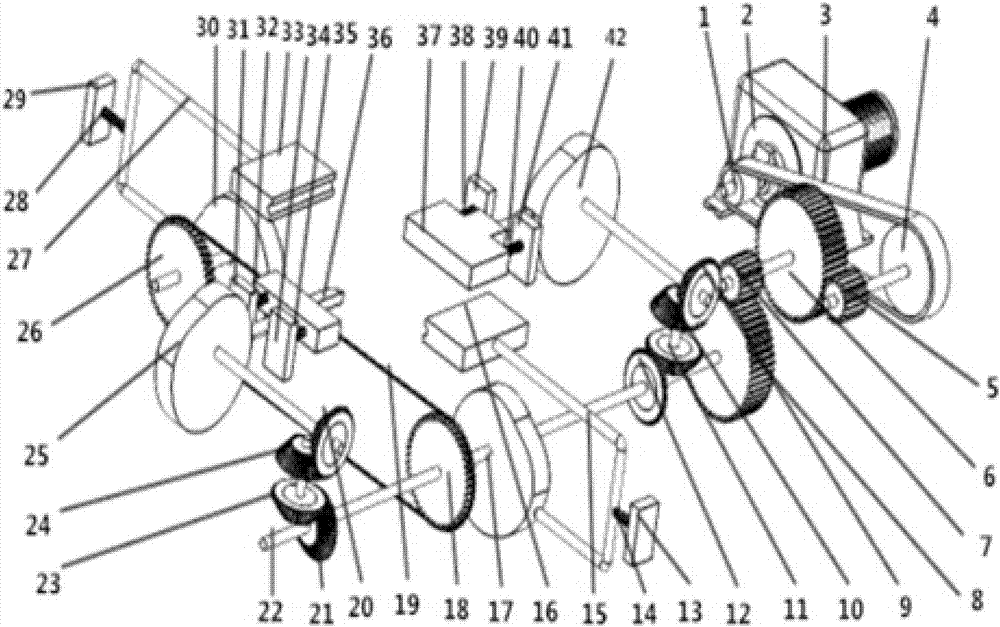

[0024] Such as Figure 1~4 As shown, a workpiece automatic forming machine tool cutting mechanism, it includes:

[0025] power system;

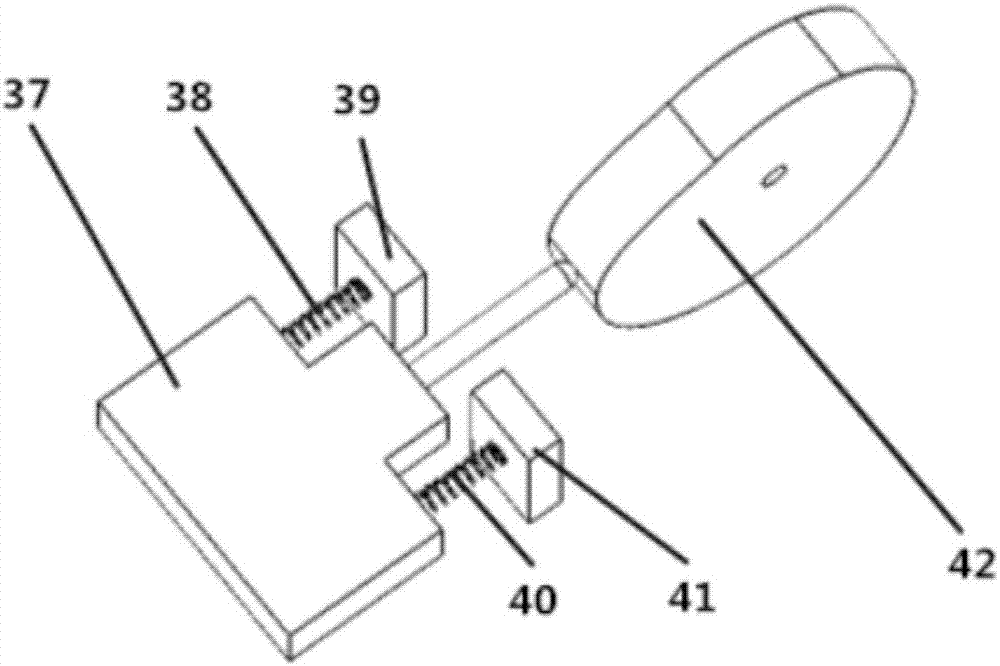

[0026] The feeding mechanism, the feeding mechanism includes a feeding slider 37 and a feeding slider driving mechanism, and the power system is connected with the feeding slider 37 through the feeding slider driving mechanism, so that when the power system moves, the described feeding slider 37 is driven Do reciprocating motion between the station to be sent and the cutting station, so as to send the workpiece on the station to be sent to the cutting station;

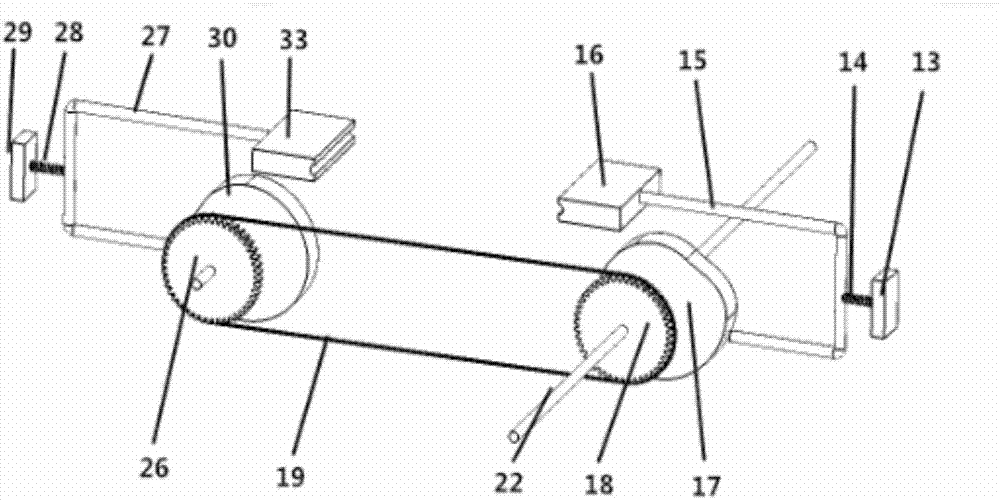

[0027] Clamping mechanism, the clamping mechanism includes the first clamping block 16, the first clamping block driving mechanism, the second clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com