Tensioning device for belt conveyor

A belt conveyor and tensioning device technology, applied in conveyors, transportation and packaging, etc., can solve the problems of expensive frequency converters, high maintenance costs, inability to transport materials, etc., and achieve wide practicability, reliable performance, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

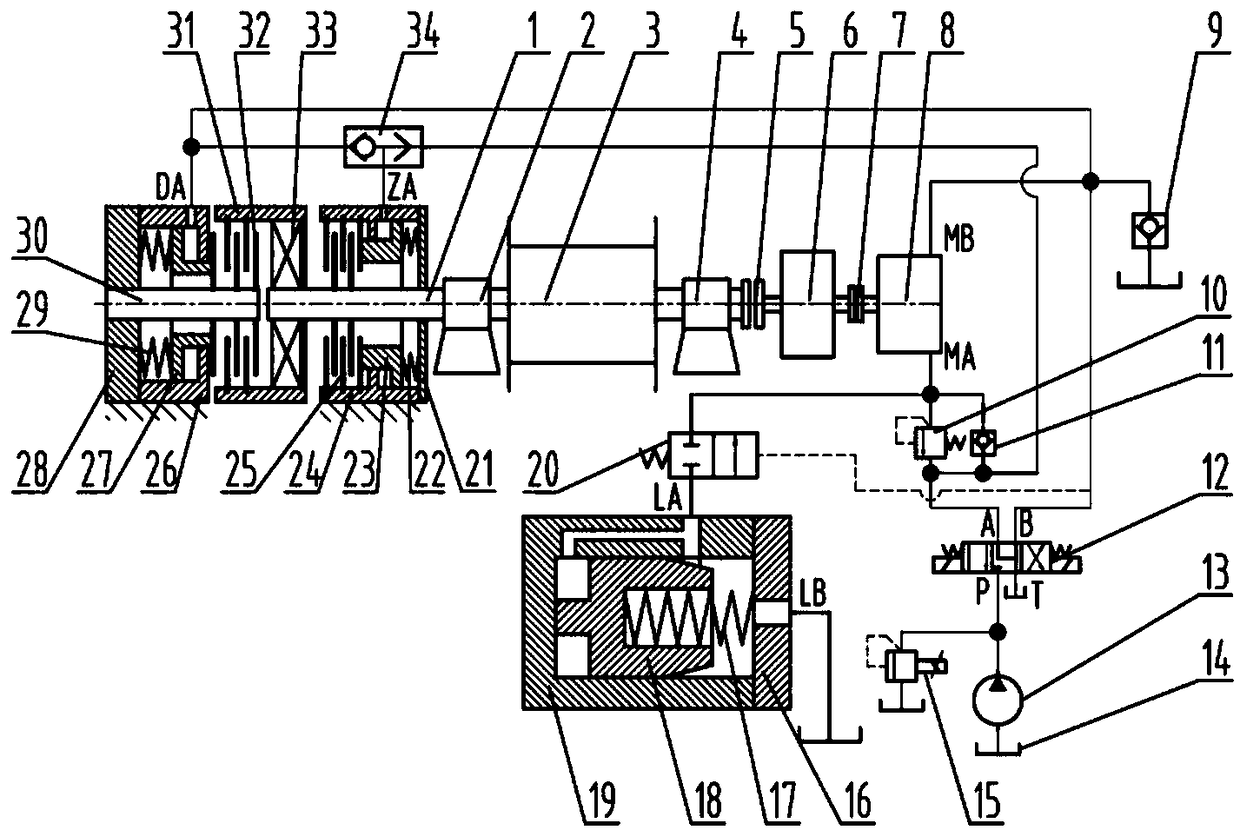

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the tensioning device of the present invention is mainly composed of a reel 3, a reducer 6, a hydraulic motor 8, a brake spring 22, a brake piston 23, a brake housing 24, a brake friction plate group 25, a one-way brake housing 26, a single One-way brake piston 27, one-way brake spring 29, one-way bearing sleeve 31, one-way brake friction plate group 32, one-way bearing 33, hydraulic pump 13 and so on. in:

[0025] The reel 3 is installed on the reel shaft 1, and is located between the left bearing seat 2 and the right bearing seat 4;

[0026] The part of the drum shaft 1 protruding from the left bearing seat 2 forms a dynamic connection with the inner friction plate of the brake friction plate group 25 through the spline, and the outer friction plate of the brake friction plate group 25 is connected with the left side of the inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com