Composite lightweight aggregate ecological cement concrete floating bed and preparation method thereof

An ecological cement and concrete technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve aging and deformation, secondary pollution, easy burning of plastics, aging and deformation, etc. problem, to achieve the effect of large porosity and improved purification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

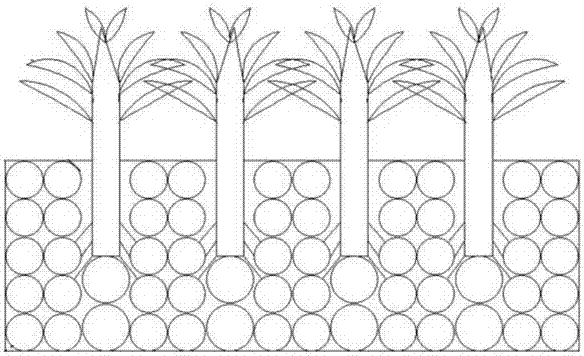

[0022] see figure 1 , in the embodiment of the present invention, a composite lightweight aggregate ecological cement concrete floating bed, the raw materials used include 20 parts by weight of pumice, 5 parts of EPS polystyrene particles, 20 parts of cement, 9 parts of water, and 0.2 parts of water reducer part, 0.1 part of coagulant, pumice particle size is 26.50-31.50mm, pumice bulk density is 300.00kg / m 3 , the diameter of EPS polystyrene particles is 20.00mm, and the packing density of EPS polystyrene particles is 14.80kg / m 3 , the cement adopts fast-hardening and early-strength sulfoaluminate cement, the water-reducing agent adopts polycarboxylate water-reducing agent, the coagulation regulator adopts boric acid components with coagulation-regulating effect, and the composite lightweight aggregate ecological cement concrete floating bed The preparation method includes the following steps: (1) put the weighed pumice stone and EPS polystyrene particles in a mixer and stir...

Embodiment 2

[0025] see figure 1 , in the embodiment of the present invention, a composite lightweight aggregate ecological cement concrete floating bed, the raw materials used include 30 parts by weight of pumice, 2 parts of EPS polystyrene particles, 30 parts of cement, 16.5 parts of water, 0.3 parts of water reducer part, 0.2 part of coagulant, pumice particle size is 26.50-31.50mm, pumice bulk density is 300.00kg / m 3, the diameter of EPS polystyrene particles is 30.00mm, and the packing density of EPS polystyrene particles is 14.80kg / m 3 , the cement adopts fast-hardening and early-strength sulfoaluminate cement, the water-reducing agent adopts polycarboxylate water-reducing agent, the coagulation regulator adopts boric acid components with coagulation-regulating effect, and the composite lightweight aggregate ecological cement concrete floating bed The preparation method includes the following steps: (1) put the weighed pumice stone and EPS polystyrene particles in a mixer and stir f...

Embodiment 3

[0028] see figure 1 , in the embodiment of the present invention, a composite lightweight aggregate ecological cement concrete floating bed, its raw materials include 24 parts by weight of pumice, 4 parts of EPS polystyrene particles, 24 parts of cement, 13 parts of water, 0.25 parts of water reducer parts, 0.15 parts of coagulant, pumice particle size is 26.50-31.50mm, pumice bulk density is 300.00kg / m 3 , the diameter of EPS polystyrene particles is 20.00mm, and the packing density of EPS polystyrene particles is 14.80kg / m 3 , the cement adopts fast-hardening and early-strength sulfoaluminate cement, the water-reducing agent adopts polycarboxylate water-reducing agent, the coagulation regulator adopts boric acid components with coagulation-regulating effect, and the composite lightweight aggregate ecological cement concrete floating bed The preparation method includes the following steps: (1) put the weighed pumice stone and EPS polystyrene particles in a mixer and stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com