A kind of pressure index modifier of solid propellant

A solid propellant and regulator technology, which is applied in the production of compressed gas, offensive equipment, non-explosive/non-thermal agent components, etc. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

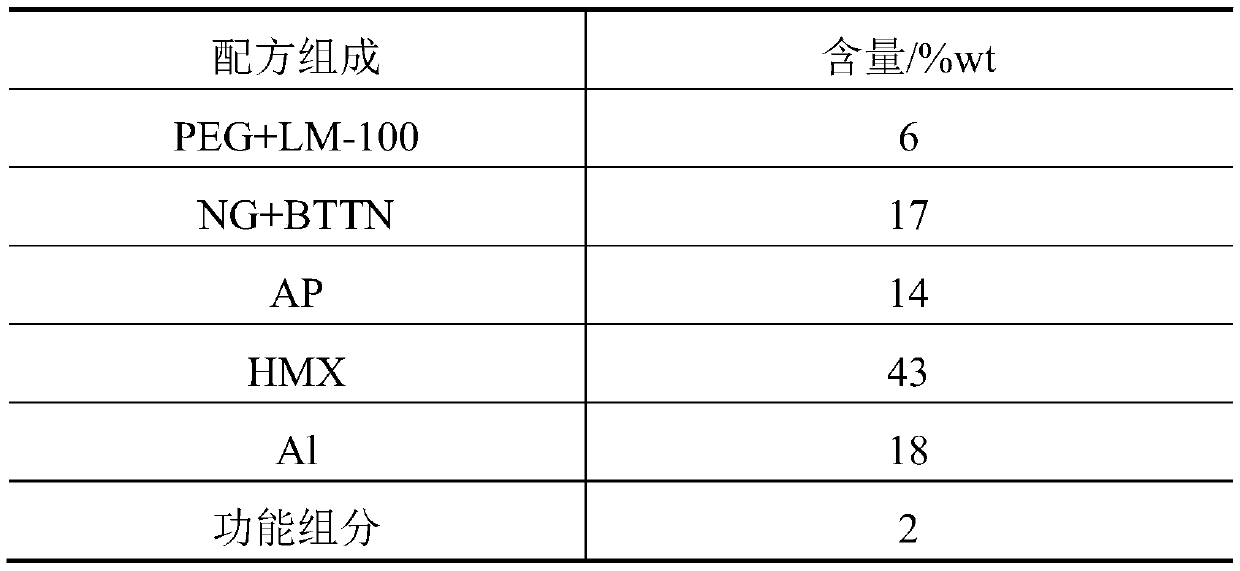

[0019] PEG / NG / BTTN / HMX propellant blank formulation, Co-free 3 o 4 ·CuO composite metal oxide pressure index regulator, see Table 1 for propellant composition.

[0020] Table 1 PEG / NG / BTTN / HMX propellant blank formula composition

[0021]

[0022] Does not contain Co 3 o 4 The combustion performance of the CuO composite metal oxide pressure index modifier blank propellant formula is as follows:

[0023] 1) Propellant burning rate at standard pressure of 6.86MPa: r 6.86MPa =12.82mm / s

[0024] 2) Under the pressure of 3-12MPa, the pressure exponent of propellant burning rate conforms to r=3.2666p 0.71 , n=0.71

Embodiment 2

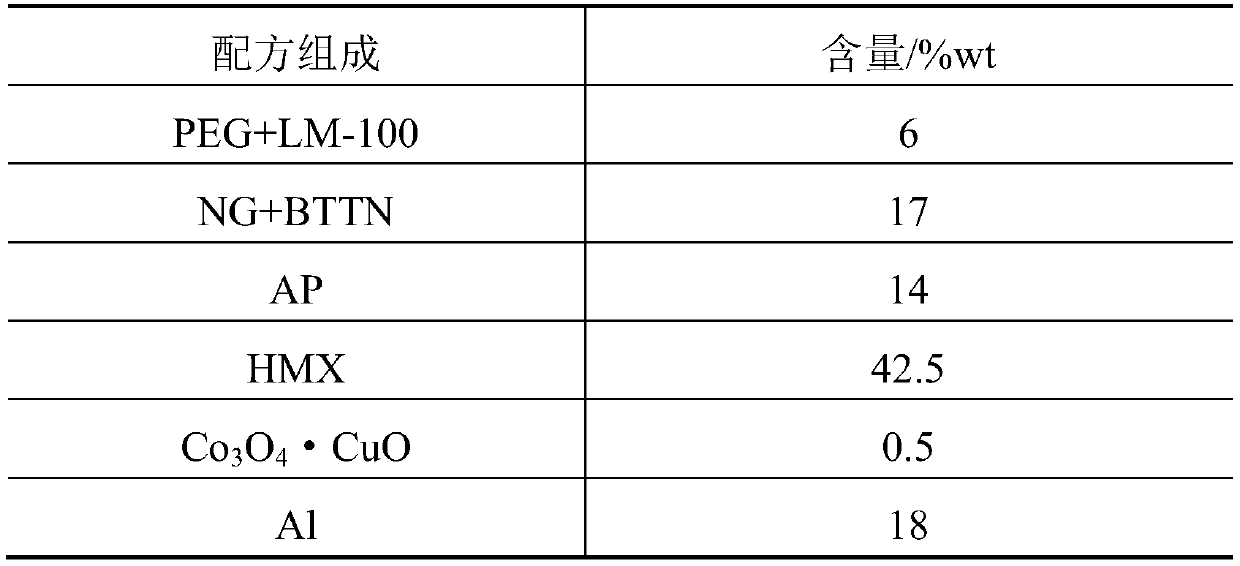

[0026] PEG / NG / BTTN / HMX propellant blank formulation, add 0.5% Co 3 o 4 ·CuO composite metal oxide pressure index regulator, see Table 2 for propellant composition.

[0027] Table 2 PEG / NG / BTTN / HMX propellant formulation composition

[0028]

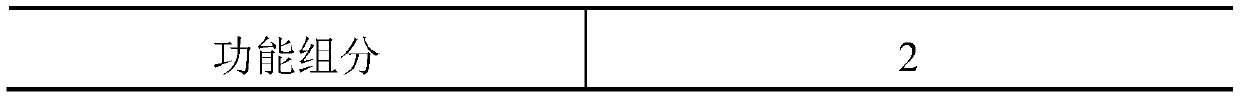

[0029]

[0030] Contains 0.5% Co 3 o 4 The combustion performance of the propellant formula of the CuO composite metal oxide pressure index regulator is as follows:

[0031] 1) Propellant burning rate at standard pressure of 6.86MPa: r 6.86MPa =12.80mm / s

[0032] 2) Under the pressure of 3-12MPa, the pressure exponent of propellant burning rate conforms to r=3.7322p 0.64 , n=0.64

Embodiment 3

[0034] In the blank formula of PEG / NG / BTTN / HMX propellant, add 1.0% Co 3 o 4 ·CuO composite metal oxide pressure index modifier, see Table 3 for propellant composition.

[0035] Table 3 PEG / NG / BTTN / HMX propellant formulation composition

[0036]

[0037] Contains 0.5% Co 3 o 4 The combustion performance of the propellant formula of the CuO composite metal oxide pressure index regulator is as follows:

[0038] 1) Propellant burning rate at standard pressure of 6.86MPa: r 6.86MPa =12.81mm / s

[0039] 2) Under the pressure of 3-12MPa, the pressure exponent of propellant burning rate conforms to r=4.6163p 0.53 , n=0.53

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com