Pulverized coal feeding control device and pulverized coal feeding control method

The technology of a control device and a feeding device, which is applied to the feeding tool of the gasification device, the gasification of granular/powder fuel, transportation and packaging, etc., can solve the problems of unstable transportation, high operation intensity and low transportation accuracy, etc. Achieve the effects of high timing control accuracy, reduced operation intensity, and high execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

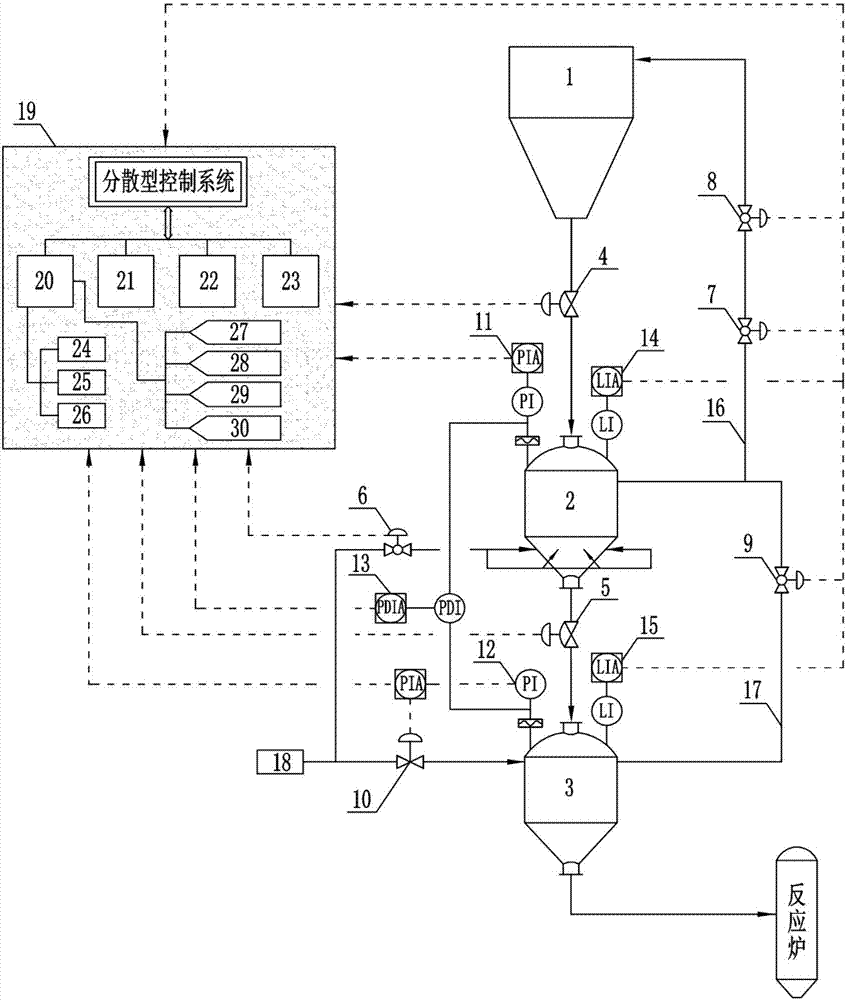

[0039] see figure 1 , the pulverized coal feeding control device of the present invention includes a feeding device body and a control system;

[0040] The feeding device body includes a coal hopper 1, a pulverized coal lock hopper 2 and a pulverized coal hopper 3 connected in sequence;

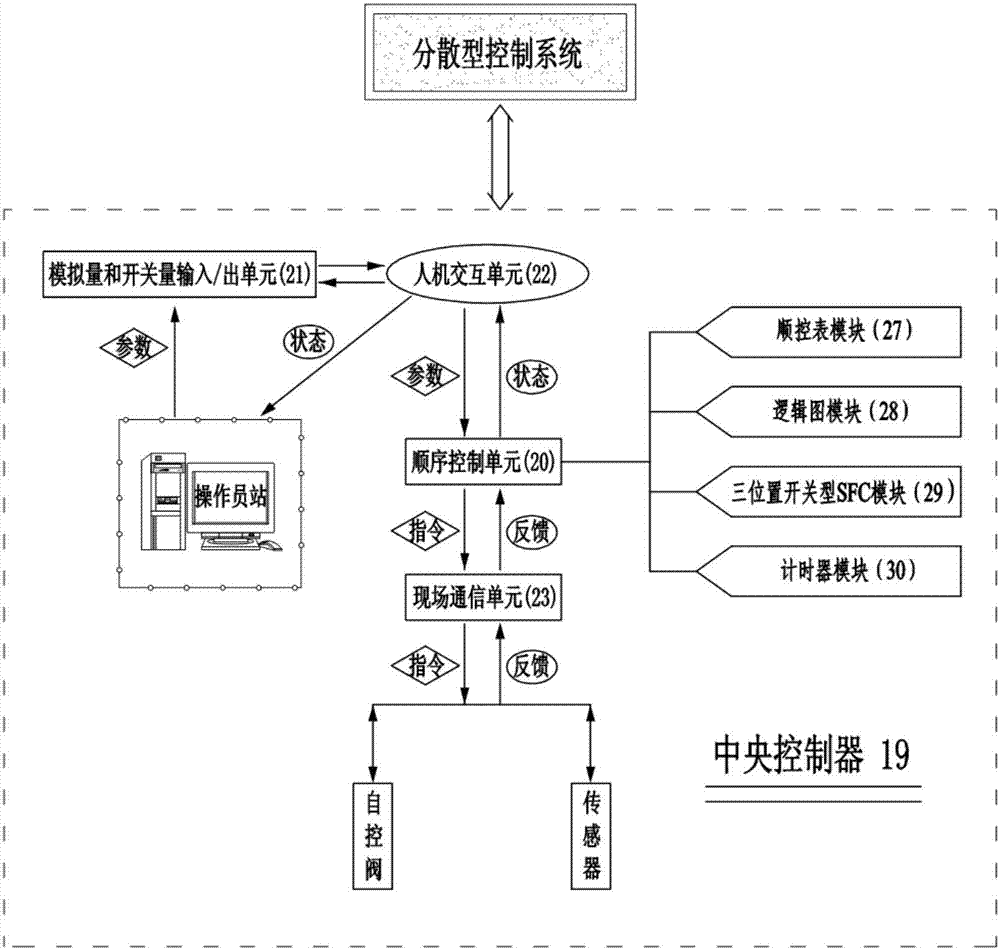

[0041] Described control system comprises central controller 19 and the automatic control valve and the sensor that link to each other with central controller 19;

[0042] The self-control valve includes a lock hopper feed valve 4 installed between the coal hopper 1 and the pulverized coal lock hopper 2, a lock hopper discharge valve 5 installed between the pulverized coal lock hopper 2 and the pulverized coal hopper 3, The lock hopper pressure valve 6 installed between the gas source 18 and the pulverized coal lock hopper 2, the feed hopper pressure regulating valve 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com