Method and system for automatically switching states in electrolytic cell in copper electrolysis workshop

An automatic conversion and electrolytic cell technology, which is applied in the electrolytic process, electrolytic components, photography technology, etc., can solve the problems that the real-time monitoring of the state in the electrolytic cell cannot affect the production efficiency and safety of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

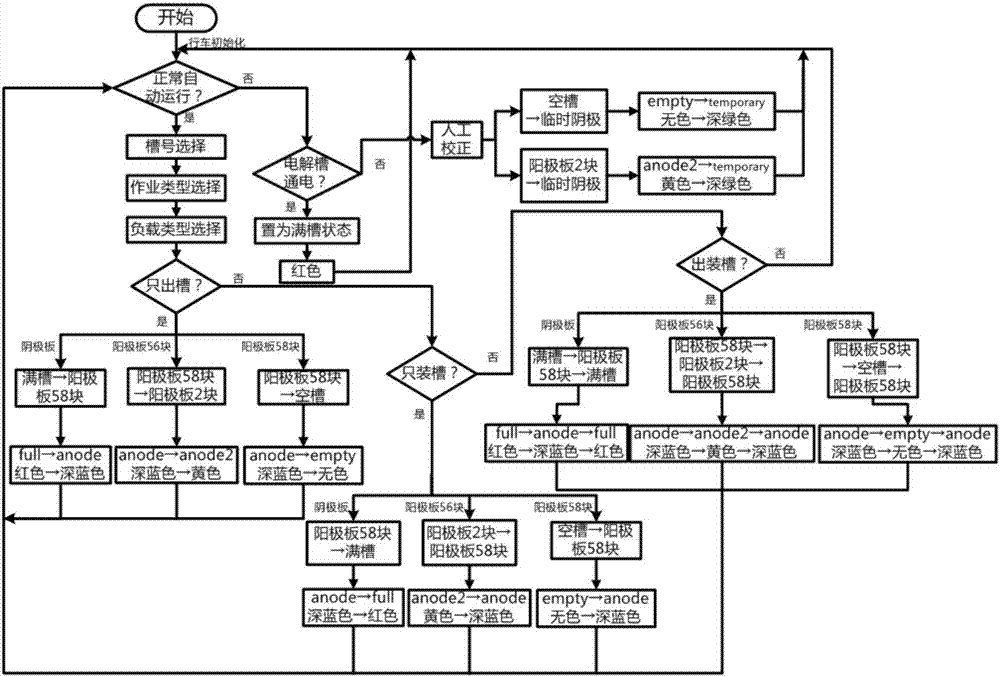

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

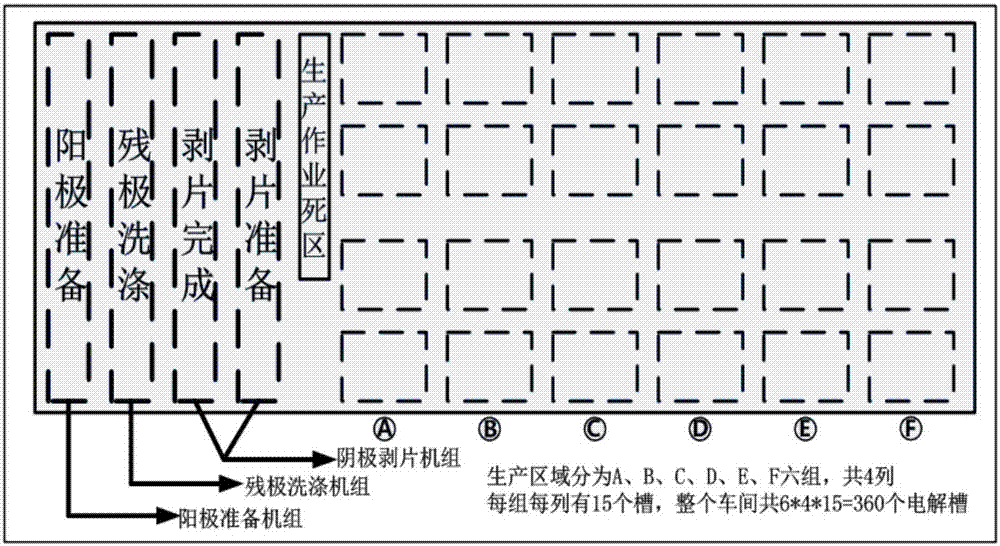

[0029] It should be noted that the electrolysis cycle of cathode and anode plates in the copper electrolysis workshop of the present invention is fixed. At the end of the cycle, the copper electrolysis crane must quickly complete the renewal of the electrolytic cell plate, and the state information in the electrolytic cell changes accordingly. The copper electrolysis crane is erected on the On the electrolyzer, it is mainly used for plate handling, and runs back and forth between the ground unit area and the electrolyzer area.

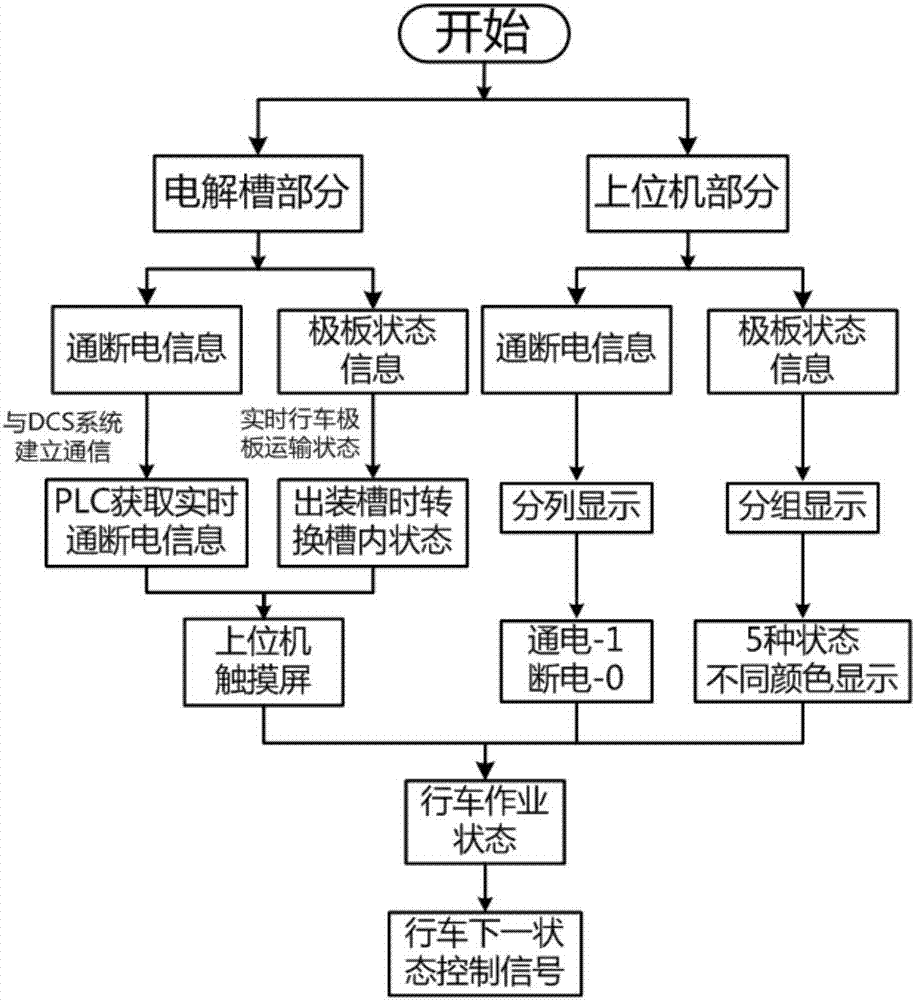

[0030] see figure 1 As shown, the present invention provides a method for automatically switching the state in the electrolytic tank of a copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com