Steel protection tube following method under deep water inclined rock surface condition

A steel casing and rock surface technology, applied in water conservancy projects, coastline protection, embankments, etc., can solve the problems of deformation damage, high cost, steepness, etc., and achieve the effect of easy control of plane position, easy control of verticality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

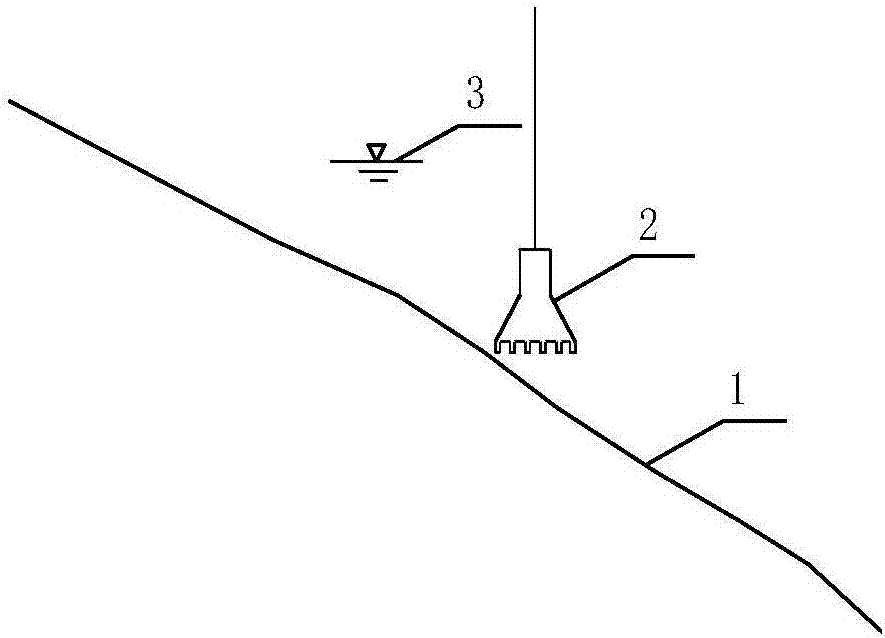

[0057] Step 1, such as figure 1 As shown, a drilling platform is built at the pier position, an impact drilling rig is placed at the drilling pile position of the drilling platform, and the drill bit 2 of the impact drilling rig impacts the exposed rock surface 1 below the water surface 3 without a steel casing .

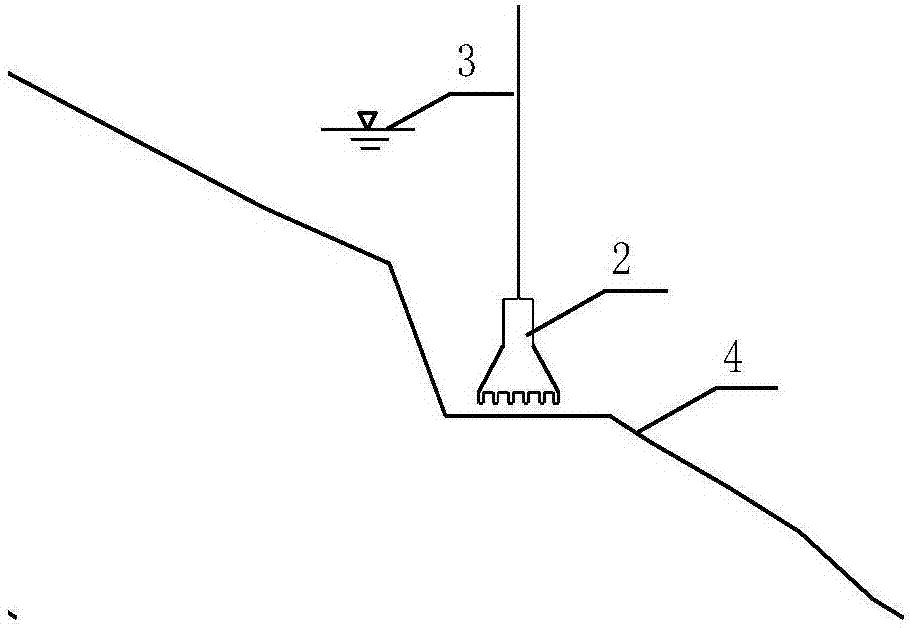

[0058] Step 2, such as figure 2 As shown, the drill bit 2 impacts the exposed rock face 1 to form a partially flattened rock face 4 .

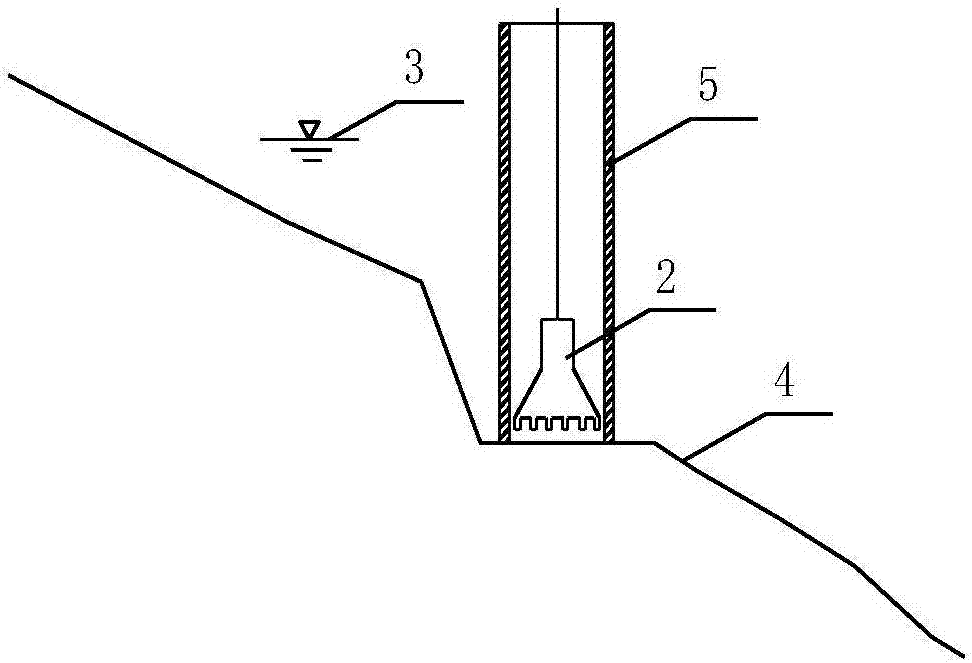

[0059] Step 3, if image 3 As shown, lower the steel casing 5, and after the steel casing 5 contacts the rock surface 4, lower the drill bit 2 in the steel casing 5.

[0060] Step 4, such as Figure 4 As shown, the drill bit 2 impacts the rock formation inside the steel casing, so that the rock surface 4 gradually forms a hole 6 with a certain depth and a diameter approximately the same as the outer diameter of the steel casing.

[0061] Step 5, such as Figure 5 As shown, mention the drill bit 2, place an alternative beating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com