Method for applying large-diameter well sinking by utilizing underground shaft robot

A robot, large-diameter technology, applied in mechanically driven excavators/dredgers, excavation, caisson, etc., can solve problems such as the inability of construction equipment to operate underwater, aggravate the surface subsidence of the construction site, and affect the safety of surrounding buildings, etc. Wide excavation range and adaptability, avoiding skew and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

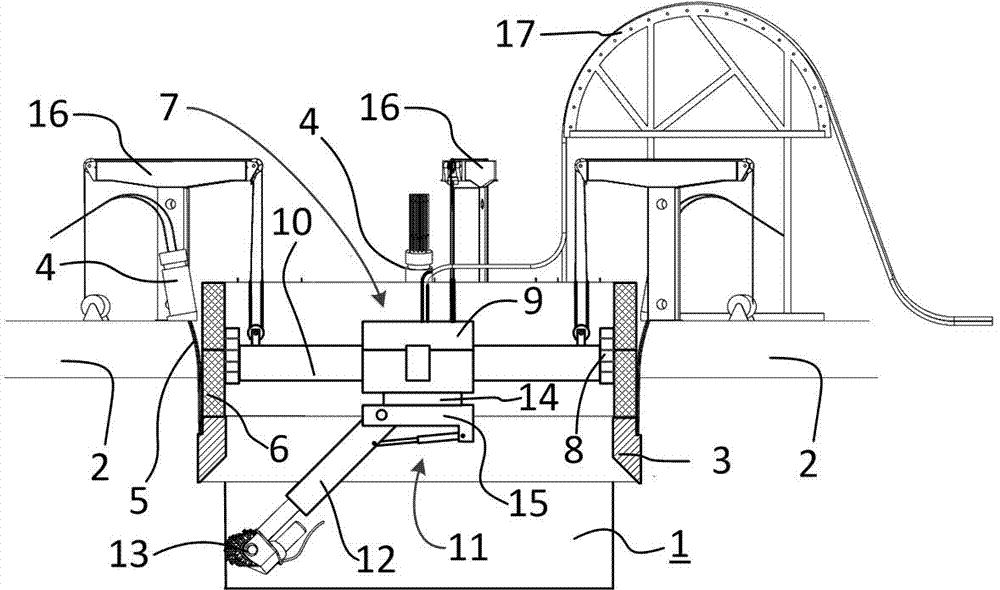

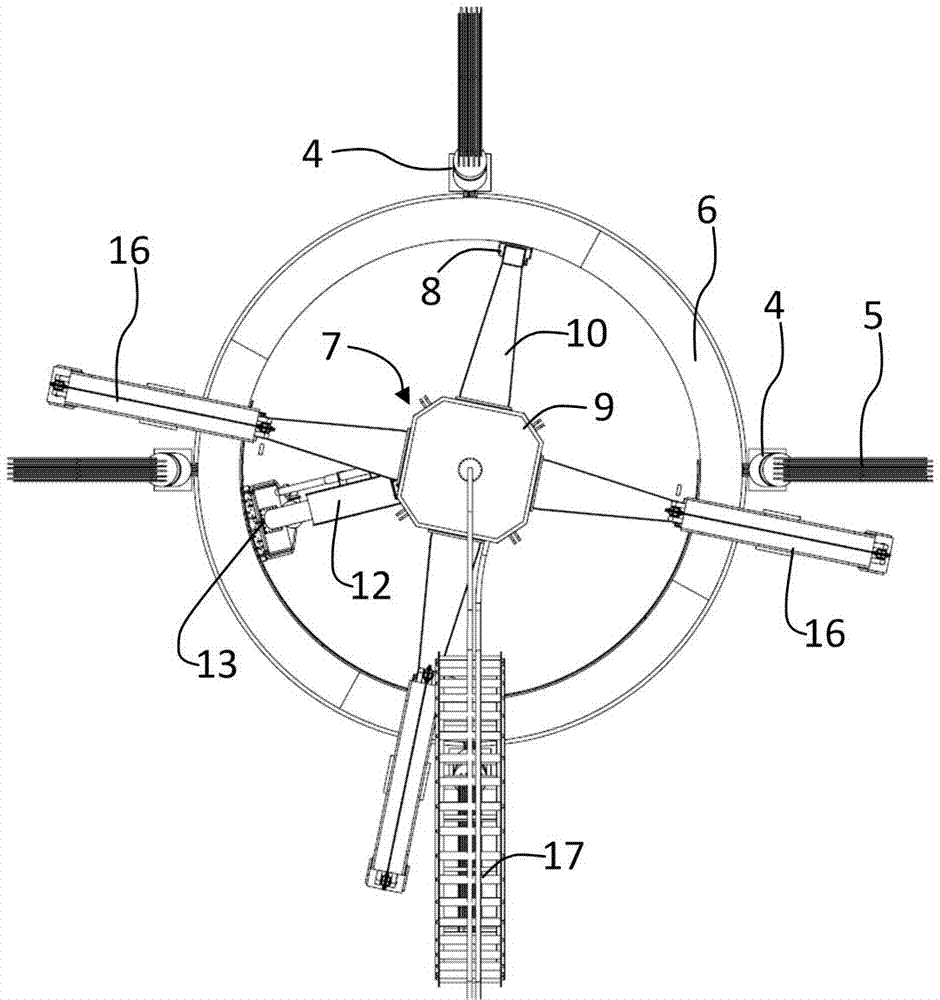

[0024] Embodiment: This embodiment specifically relates to a method for using an underground shaft robot to construct a large-diameter caisson, and the method includes the following steps:

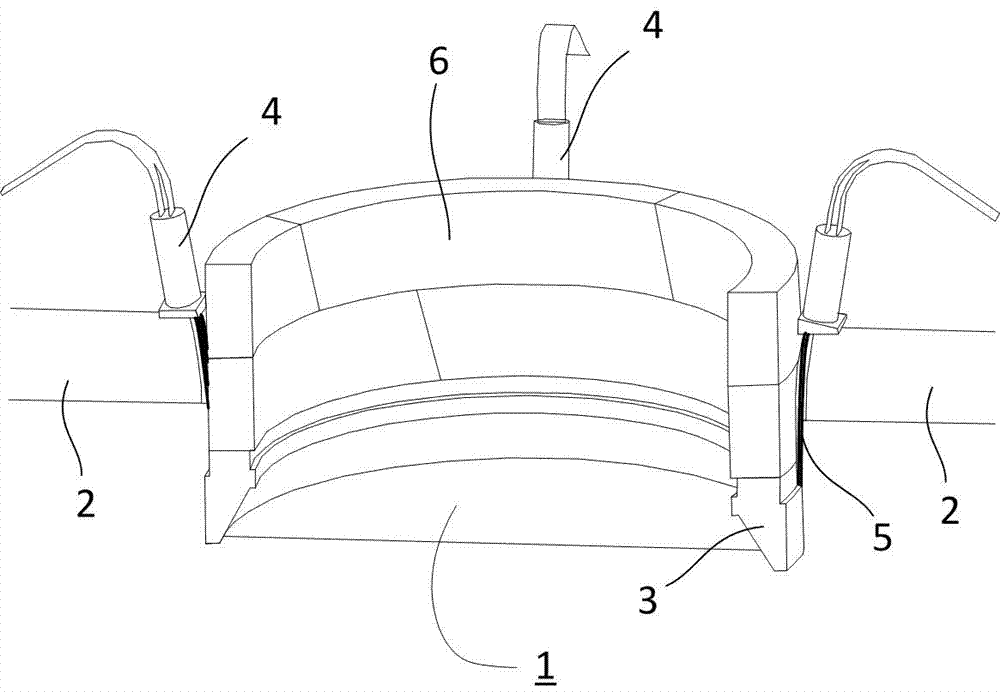

[0025] (1) if figure 1 As shown, the foundation pit 1 is excavated at the preset position of the caisson, and the reinforced concrete foundation 2 is poured on the surface around the foundation pit 1 to install the equipment required for the sinking of the caisson and bear the force of the sinking of the caisson; After the construction of the concrete foundation 2 is completed, the blade foot ring 3 is assembled, and the blade foot ring 3 is hoisted into the foundation pit 1; the blade foot ring 3 is ring-shaped, and its bottom edge is provided with a sharp blade foot for cutting soil.

[0026] After the hoisting of the blade foot ring 3 is completed, four lowering devices 4 are installed on the surface of the reinforced concrete foundation 2 outside the foundation pit 1 (of course, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com