Repulsion type magnetic suspension shock insulation supporting base and manufacturing construction method thereof

A seismic isolation bearing and magnetic levitation technology, which is applied in the directions of earthquake resistance, building type, building structure, etc., can solve the problems of high cost, many equipment, large volume, etc., and achieves low size and cost, good effect, and eliminates mental stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

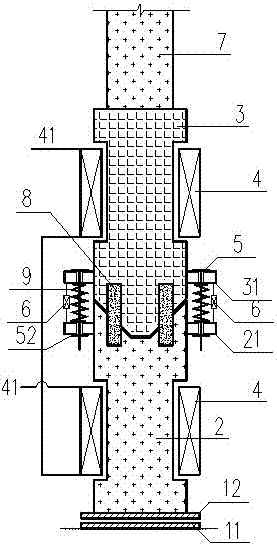

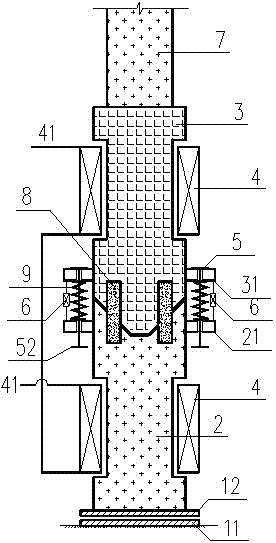

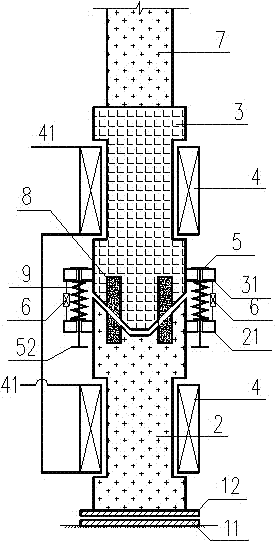

[0033] Such as Figure 1~3 Shown is a longitudinal sectional view of Embodiment 1 of the present invention. The upper electromagnet 3 is provided with a downwardly convex conical protrusion, the lower electromagnet 2 is provided with a concave conical groove, and the coil 4 is wound around the electromagnet. Under normal state, upper electromagnet 3 is inserted in lower electromagnet 2; It is tapered and symmetrical, the horizontal repulsion between the electromagnets counteracts each other to maintain the automatic centering ability, the vertical repulsion between the electromagnets makes the upper electromagnet 3 suspend, and drives the structural load-bearing member 7 fixed on the upper electromagnet 3 to float.

[0034] In order to prevent the structural load-bearing member 7 on the upper electromagnet 3 from floating too high, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com