Pulsed plasma thruster based on electrothermal-electromagnetic hybrid accelerating

A pulsed plasma and electromagnetic mixing technology, applied in the field of plasma, can solve the problems of low utilization rate of working medium, low specific impulse parameters of thrusters, inability to satisfy thrusters at the same time, etc., achieving less moving parts, small size, and improved energy The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

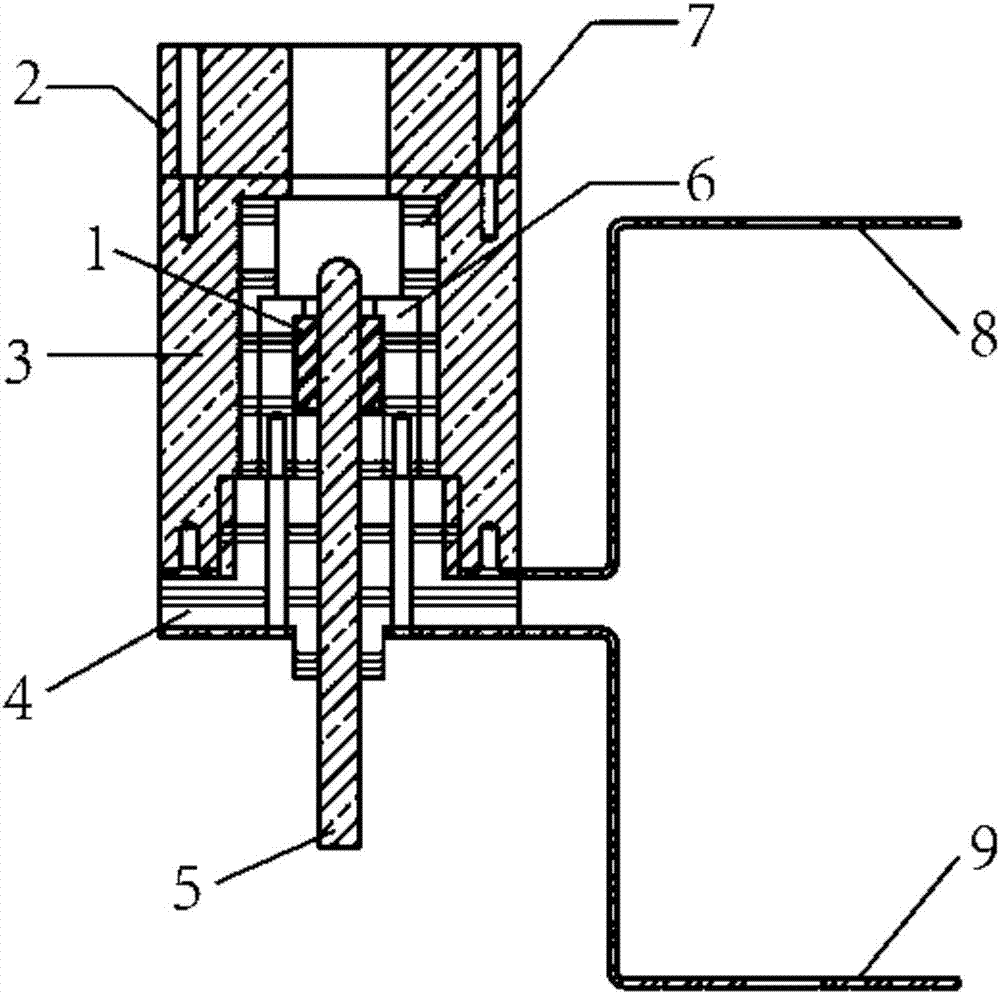

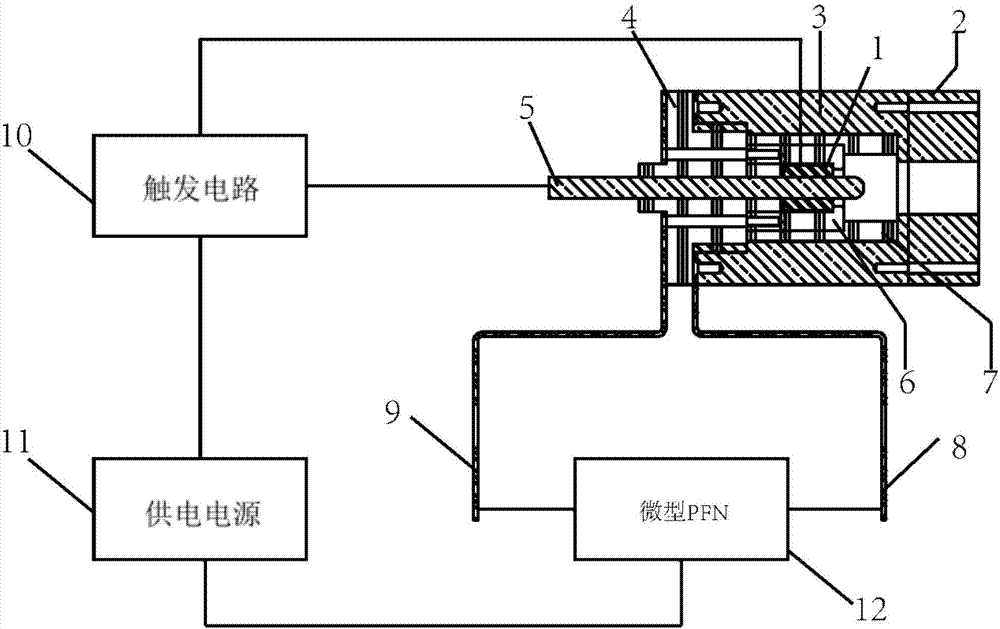

[0020] In one embodiment, combined with figure 1 , figure 2 , the disclosure discloses a pulsed plasma thruster based on electrothermal electromagnetic hybrid acceleration,

[0021] The thruster includes: a power processing unit, a trigger, a trigger circuit, a main discharge circuit, a capillary discharge cavity, a coaxial accelerating electrode and a semiconductor spark plug; the power processing unit supplies power to the main discharge circuit;

[0022] The main discharge circuit is used to apply a high voltage between the anode and the cathode of the thruster before the thruster is ignited, so that the radial and axial electric fields are distributed inside the capillary discharge cavity;

[0023] The trigger circuit outputs high-voltage pulses to the trigger;

[0024] Under the action of the pulse high voltage output by the trigger circuit, the trigger generates surface flashover and releases initially charged particles, and the initially charged particles enter the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com