Double-flexibility and three-speed speed adjusting water pump

A dual-flexible, speed-adjustable technology, applied in the field of auto parts, can solve problems such as poor warm air effect, slow increase of cylinder wall temperature, and aggravated engine wear in cold state, so as to improve warm air effect, improve lubrication efficiency, reduce The effect of cold wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

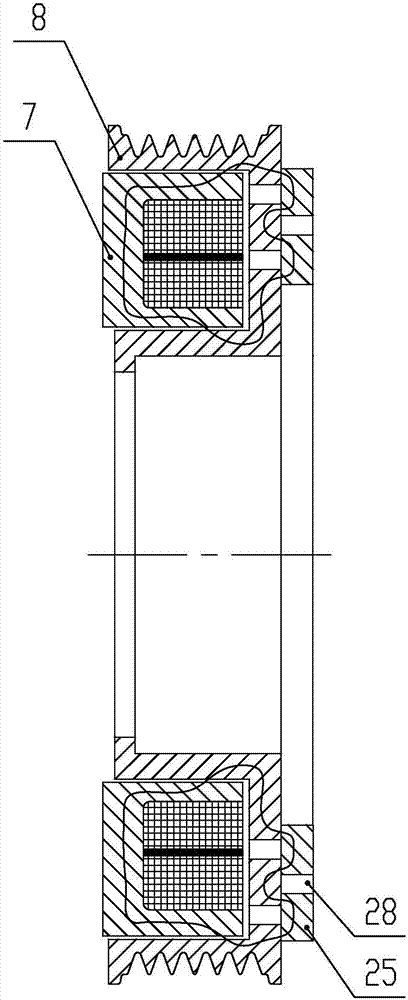

[0023] Such as Figure 4 As shown, the double-flexible three-speed speed-regulating water pump in this embodiment includes a water pump casing 1, a pulley 8, and a water pump shaft 4. The water pump shaft 4 is a shaft-connected bearing. The left end is equipped with water seal 3 and impeller 2, and the right end of water pump shaft 4 passes through the center hole of water pump casing 1 and extends out of water pump casing 1. Water pump casing 1 is equipped with double-row bearing 9, and pulley 8 is set on the water pump through double-row bearing 9. On the shell 1, the inner ring of the double row bearing 9 is fixedly connected with the water pump casing 1, and the outer ring of the double row bearing 9 is fixedly connected with the pulley 8, and the pulley 8 can rotate around the double row bearing 9.

[0024] Such as figure 2 and Figure 4 As shown, the inner cavity of the pulley 8 is equipped with an electromagnet core 7, the electromagnet core 7 is fixedly connected wi...

Embodiment 2

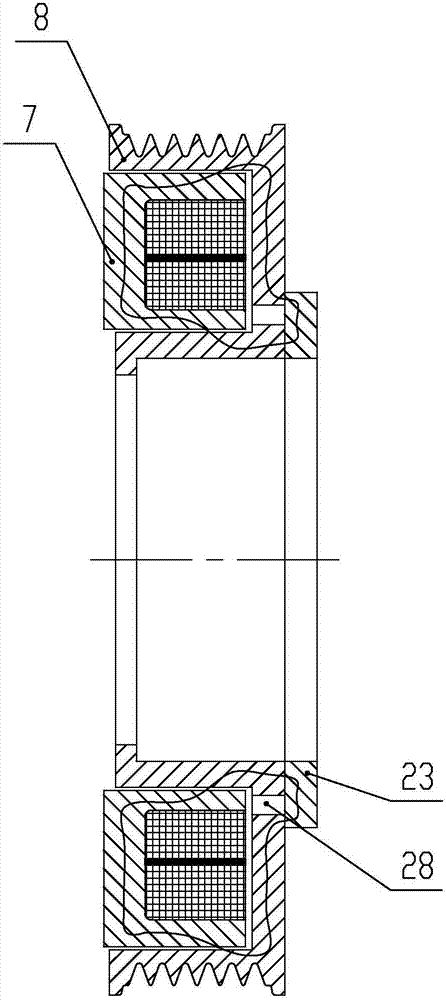

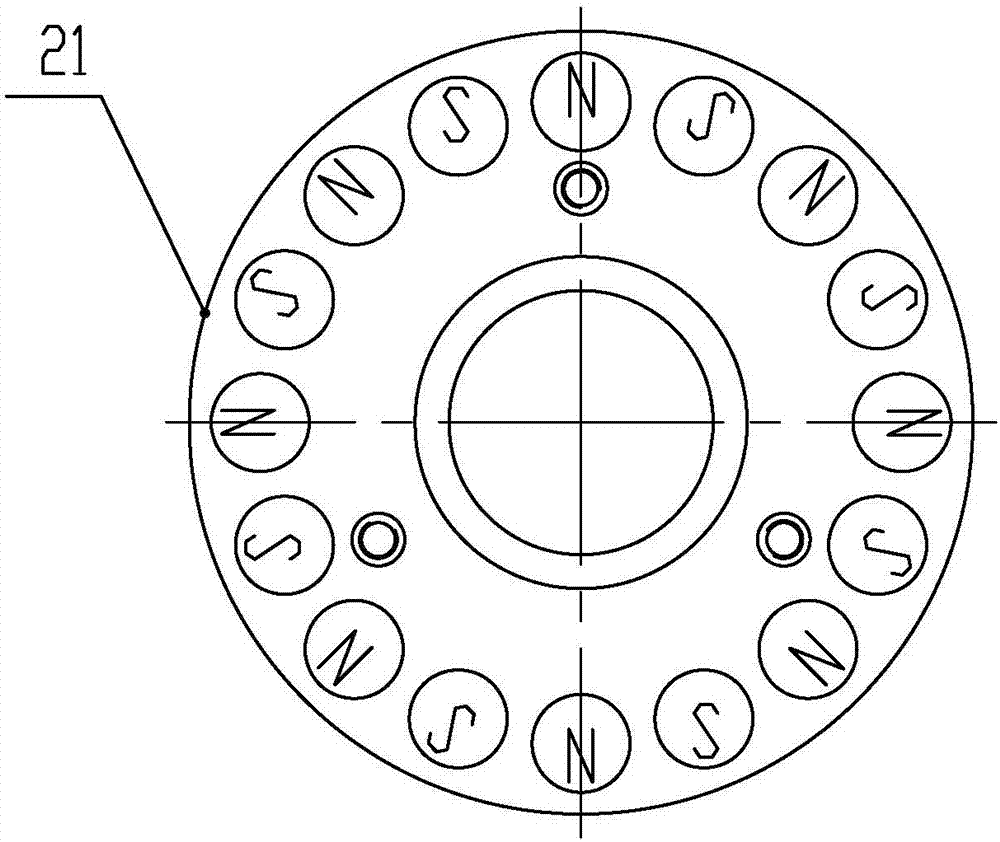

[0031] The difference between the second embodiment and the first embodiment is that the second embodiment does not include the drive disc 11 and the soft iron disc 19, and of course there is no cavity formed by the drive disc 11 and the pulley 8, and the positions of the two turns of the soft iron disc are changed. Among them, the two circles of soft iron discs are: the soft iron disc 15' located in the inner ring and the soft iron disc 17' located in the outer ring, the position of the soft iron disc 15' located in the inner ring and the permanent magnet 14 on the magnet fixing disc 21 Correspondingly, a permanent magnet 18 ′ is embedded on the outer end surface of the pulley 8 , and the soft iron disk 17 ′ on the outer ring corresponds to the position of the permanent magnet 18 ′ on the pulley 8 .

[0032] The working principle and working process of the second embodiment are basically the same as those of the first embodiment, and will not be repeated here.

[0033] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com