Closed-type pump-controlled hydraulic system

A hydraulic system and closed pump technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems of large space occupation, hydraulic system application restrictions, and high cleanliness requirements, and achieve shrinkage Occupied space, reduced power loss, and the effect of meeting system requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the following embodiments are illustrative only and not limitative of the present invention. The protection scope of the present invention is defined by the claims. It should also be understood that in implementing the present invention, it is not necessary to include all technical features in all the following embodiments, and these technical features can be combined in various ways.

[0023] Hereinafter, the words "first" and "second" are just for description, not restrictive, and do not have any restrictive effect on the structure.

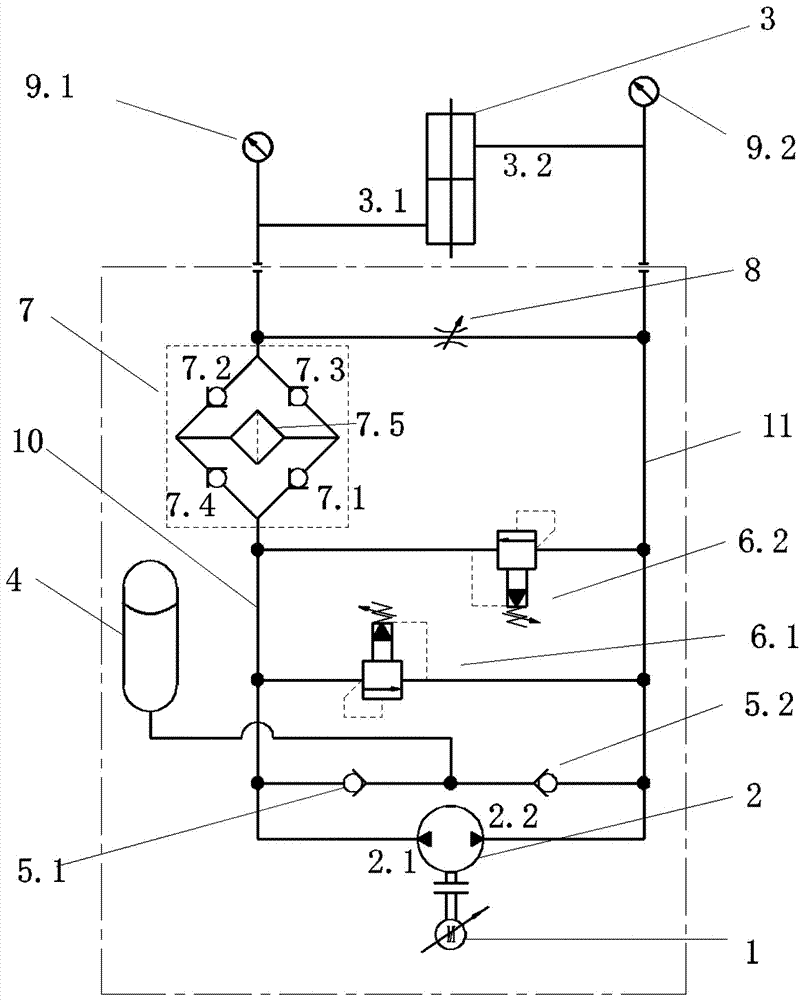

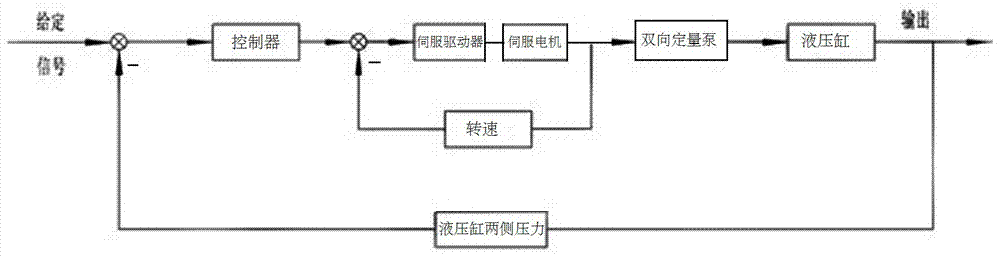

[0024] figure 1 A schematic schematic diagram of a closed pump control hydraulic system according to an embodiment of the present invention is shown, the closed pump control hydraulic system includes: an AC servo motor 1, a bidirectional quantitative pump 2, and two overflow valves 6 And the hydraulic cylinder 3, the output shaft of the AC servo motor 1 is connected to the input shaft of the bidirectional q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com