Online automatic ash clearing device of fire tube type waste heat boiler

A waste heat boiler and automatic ash cleaning technology, which is applied in the fields of solid residue removal, lighting and heating equipment, combustion product treatment, etc. Function and other issues to achieve the effect of ensuring the safe operation of equipment, obvious economic and social benefits, and reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

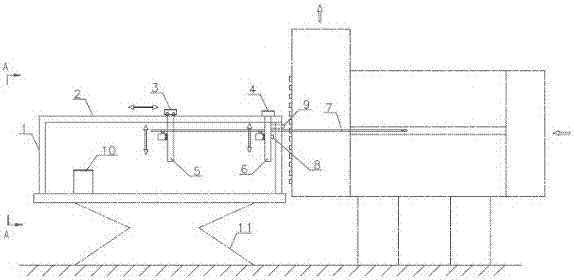

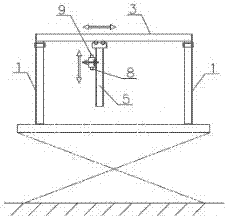

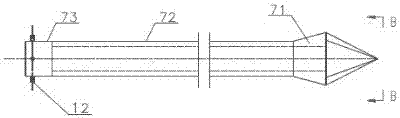

[0037] Such as Figure 1-Figure 4 As shown, an online automatic ash removal device for a fire tube waste heat boiler includes a lifting platform 11, a column 1, a control system, a monitoring system, a positioning system, a drive system and a cleaning gun 7, and the column 1 is fixedly connected to the lifting platform 11 , the control system is respectively connected with the monitoring system, the positioning system, and the drive system, the drive system is connected with the cleaning gun 7, the drive system includes a longitudinal arm, a cross arm, and a vertical arm, and the longitudinal arm includes a drive longitudinal arm 2, and the cross arm Including the rear drive cross arm 3, the front drive cross arm 4, the vertical arm includes the rear drive vertical arm 5 and the front drive vertical arm 6, the control system stores the spati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com