Heat dissipation device of power module and frequency conversion air conditioner

A technology of heat dissipation device and power module, which is used in air conditioning systems, compressors with reversible cycles, and household heating, etc., can solve problems such as uncontrollable, inability to dissipate heat from modules, and failure of modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

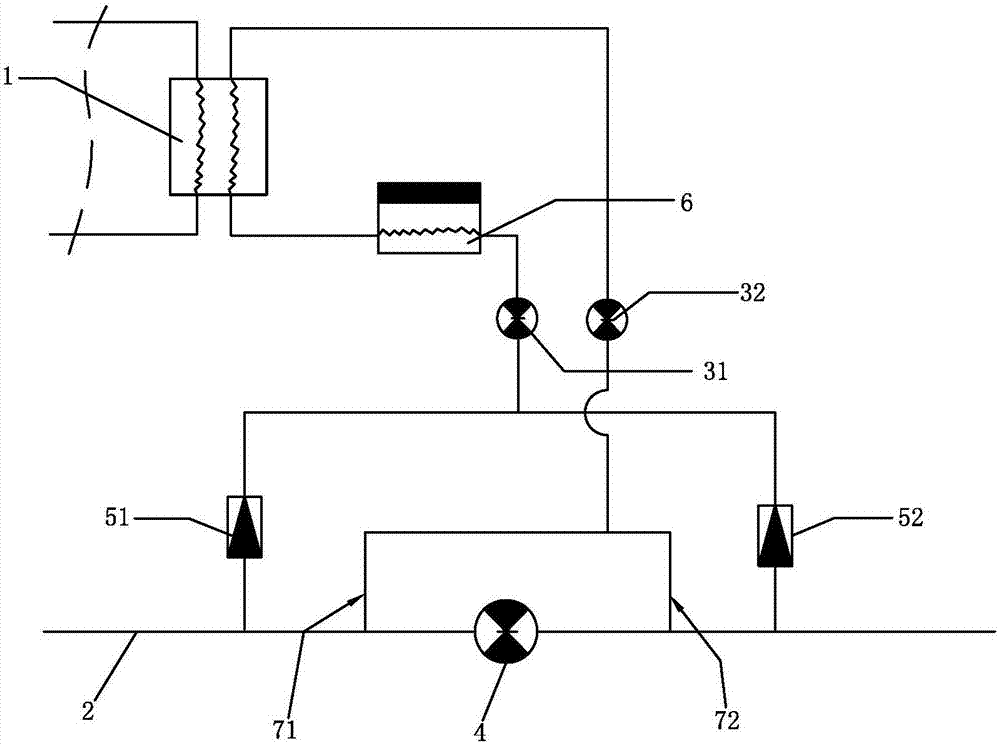

[0018] like figure 1 As shown, a heat dissipation device for a power module includes a recoverer 1, a fluorine pipeline 2, a first expansion valve 31, a second expansion valve 32, a fluorine pipeline expansion valve 4, a first single valve 51, a second one-way valve 52 and module heat exchanger 6,

[0019] The fluorine pipeline expansion valve 4 is arranged on the fluorine pipeline 2, the input ends of the first and second one-way valves 51, 52 are respectively set on the fluorine pipeline 2 at both ends of the fluorine pipeline expansion valve 4, and the output ends are connected in parallel through The first expansion valve 31 and the module heat exchanger 6 are connected to the recoverer 1;

[0020] The first branch pipe 71 communicates with the fluorine pipeline 2 between the first one-way valve 51 and the fluorine pipeline expansion valve 4, and the second branch pipe 72 communicates with the fluorine pipeline between the second one-way valve 52 and the fluorine pipeline...

Embodiment 2

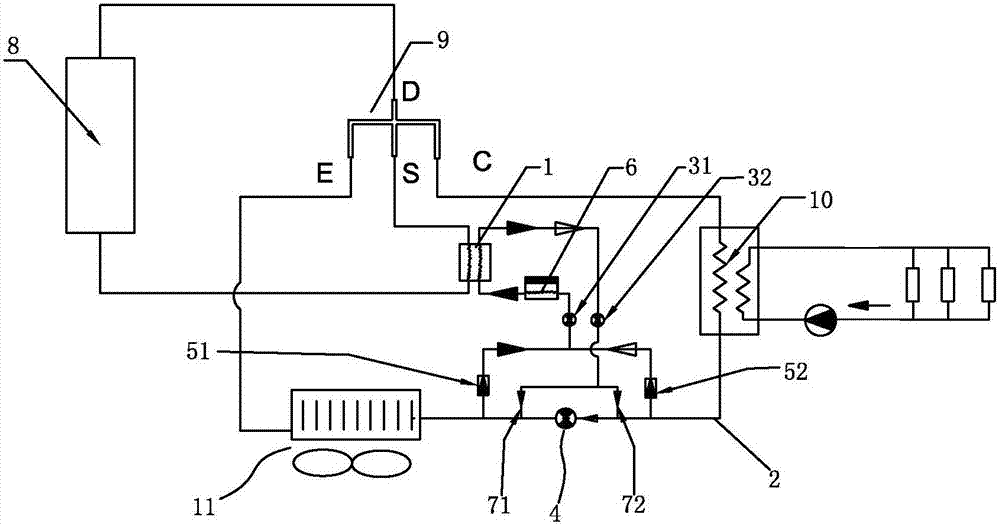

[0022] like figure 2 As shown, an inverter air conditioner includes a compressor 8, a four-way valve 9, a recoverer 1, a heat exchanger 10, an outdoor unit 11, and a fluorine pipeline 2 arranged between the heat exchanger 10 and the outdoor unit 11 Fluorine expansion valve 4. It also includes a first expansion valve 31, a second expansion valve 32, a fluorine pipeline expansion valve 4, a first check valve 51, a second check valve 52 and a module heat exchanger 6,

[0023] The input ends of the first and second one-way valves 51 and 52 are respectively arranged on the fluorine pipeline 2 at both ends of the fluorine pipeline expansion valve 4, and the output ends are connected in parallel and pass through the first expansion valve 31, the module heat exchanger 6 and the recoverer. 1 connection;

[0024] The first branch pipe 71 communicates with the fluorine pipeline between the first one-way valve 51 and the fluorine pipeline expansion valve 4, and the second branch pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com